Automatic dish-washing machine

A dishwashing machine and dishwashing technology, applied in the direction of tableware washing machine/rinsing machine, tableware washing machine/rinsing and rinsing machine parts, cleaning equipment, etc., can solve the problem of labor intensity, low work efficiency, and No high-level problems, to achieve the effect of improving dishwashing efficiency, easy operation, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

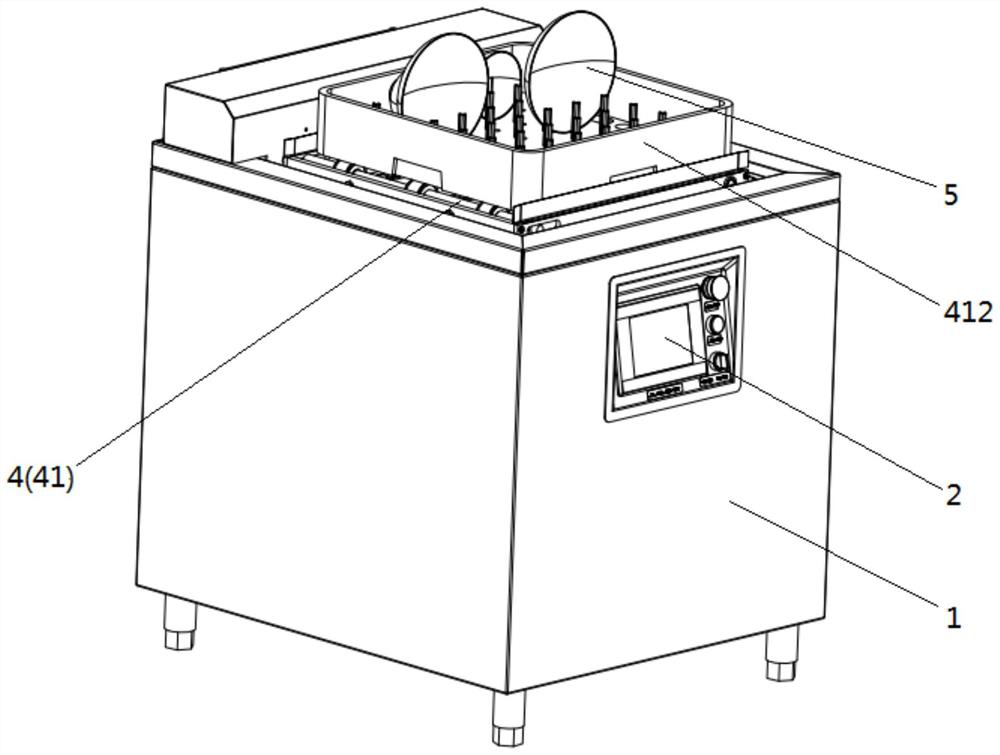

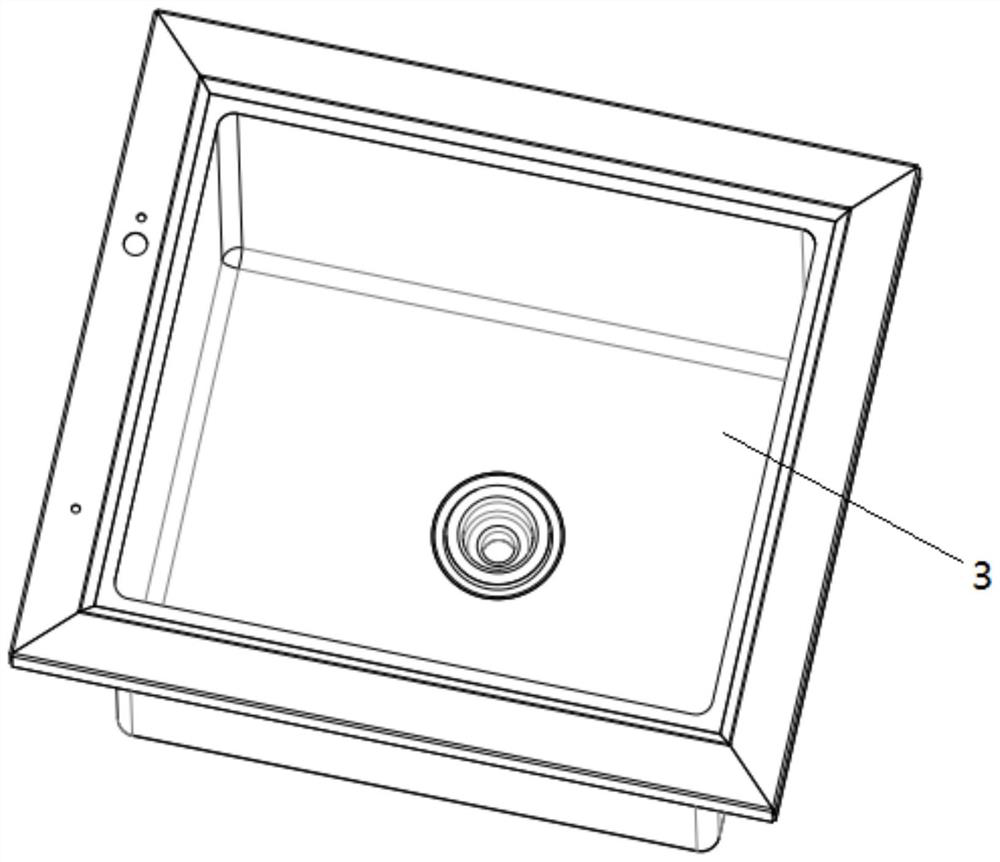

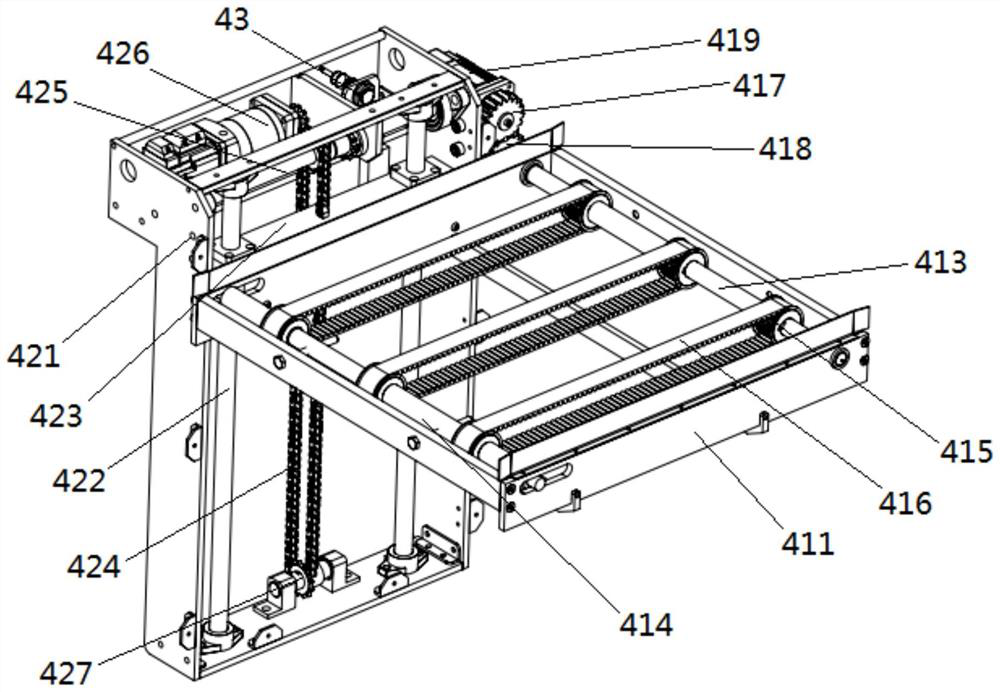

[0023] Such as Figure 1-3 As shown, an automatic dishwasher includes: a fuselage body 1, a control panel 2, a sink 3, an ultrasonic dishwasher mechanism and a transmission mechanism 4, and the control panel 2 is arranged on one side of the fuselage body 1 , the dishwashing tank 3, the ultrasonic dishwasher mechanism and the transmission mechanism 5 are all arranged inside the fuselage body 1, the transmission mechanism 4 includes a horizontal transmission component 41 and a vertical lifting component 42, and the horizontal transmission component 41 and the ultrasonic wave The dishwasher mechanism is located inside the sink 3, the vertical transfer assembly 42 is located outside the sink 3, the horizontal transfer assembly 41 is connected to the vertical lift assembly 42, and the horizontal transfer assembly 41 passes through the vertical lift assembly. 42 moves up and down inside the sink 3, the control panel 2 is used to control and monitor the working status of the sink 3, ...

Embodiment 2

[0028] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the longitudinal transmission assembly 42 includes a second longitudinal frame 441, a second lifting slide bar 442, a second lifting slide seat 443, a driving screw 444 and a third The power part 445, the second vertical frame 441 is fixed on one side of the sink 3, the upper and lower ends of the second lifting slide bar 442 are fixed on the second vertical frame 441, the second lifting slide The seat 443 slides up and down on the second lifting slide bar 442, and the upper and lower ends of the transmission screw 444 are respectively fixed on the upper and lower ends of the second longitudinal frame 441, and the transmission screw 444 is in phase with the second lifting slide 443. connected, the third power part 445 is a motor, the horizontal frame 411 is fixed on the front side of the second lift slide 443, the third power part 445 drives the transmission screw 444 to work thr...

Embodiment 3

[0030] Such as Figure 5 As shown, the difference between this embodiment and Embodiment 1 or 2 is that the longitudinal transmission assembly 42 includes a third longitudinal frame 451, a transmission roller 452, a transmission roller 453, a second transmission bearing 454, a second chain 455. The transmission steel wire 456 and the fourth power member 457. The transmission roller 452 is arranged on both sides of the outer wall of the sink 3, the third longitudinal frame 451 is fixed on the sink 3, and the transmission roller bar 453 Both the fourth power part and the fourth power part are arranged on the third longitudinal frame 451, the second transmission bearing 454 is sleeved on the transmission roller bar 453, the fourth power part 457 is a motor, and the transmission steel wire 456 is wrapped on The transmission roller 452 is connected to the outer side of the transmission roller bar 453 and the upper end of the transmission steel wire 456 is connected with the horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com