Machine vision-based disease pipeline defect classification library building and identification method

A defect classification and machine vision technology, applied in character and pattern recognition, optical test flaws/defects, instruments, etc., can solve the problems that the speed of manual recognition cannot meet the speed requirements, affect the consistency of judgment structure, and increase the probability of missed detection. Achieve a wide range of object selection, high production efficiency, and reduce misjudgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

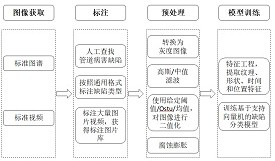

[0020] Such as figure 1 and figure 2 As shown, the present invention provides a method for classifying and identifying diseased pipeline defects based on machine vision, which is characterized in that it includes classification building and identification, and the classification method for building a database is carried out sequentially as follows:

[0021] (1) Image acquisition: collect standard pictures of pipeline diseases through the standard atlas, and collect standard videos as video materials according to the standard atlas;

[0022] (2) Image labeling stage: Call out the acquired pictures or videos, mark the defect type according to the general format, and obtain the marked picture library;

[0023] (3) Image preprocessing stage: Convert the image to a grayscale image, use Gaussian or median filter to filter the image noise, and then use the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com