Coal identification device and coal quality online monitoring system based on radio frequency identification

A radio frequency identification and monitoring system technology, applied in storage devices, supply configuration, transportation and packaging, etc., can solve problems such as flow, complex mixing, incombustibility and coordinated control problems, large uncertainties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042]The radio frequency identification-based furnace coal identification device and coal quality online monitoring system involved in the present invention will be described in detail below with reference to the accompanying drawings.

[0043]

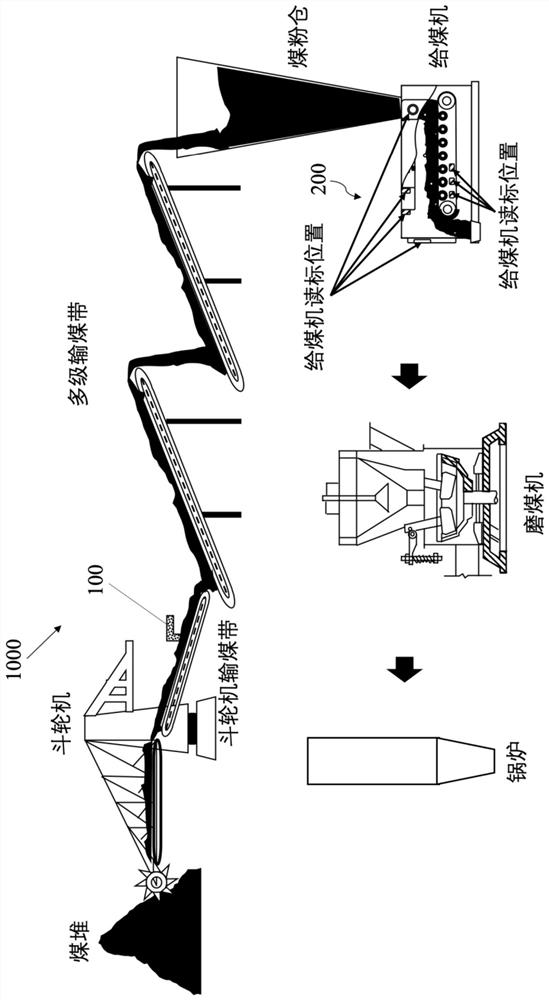

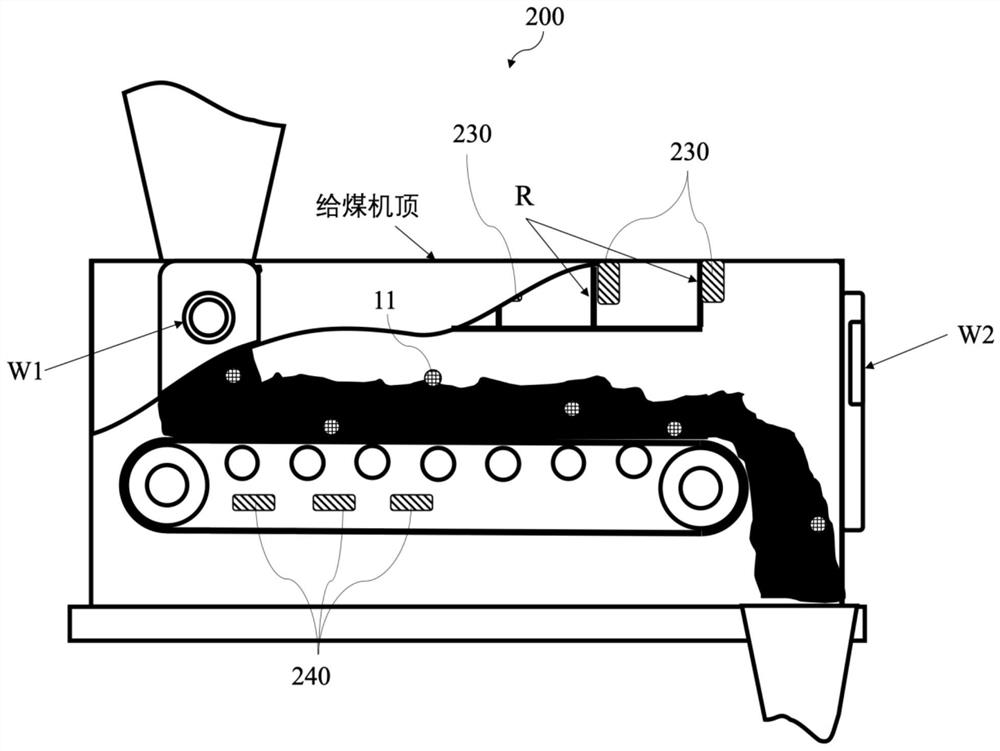

[0044] Such as figure 1 As shown, the coal quality online monitoring system 1000 includes a coal conveyor belt bidding machine 100, a furnace coal identification device 200 and a furnace coal quality determination device.

[0045] The coal conveyor belt bidding machine 100 writes the corresponding coal quality information into the radio frequency tag when the bucket wheel machine takes coal from the coal pile according to the test results of the standard coal quality of the incoming coal, and puts the radio frequency tag on the coal conveyor belt of the bucket wheel machine .

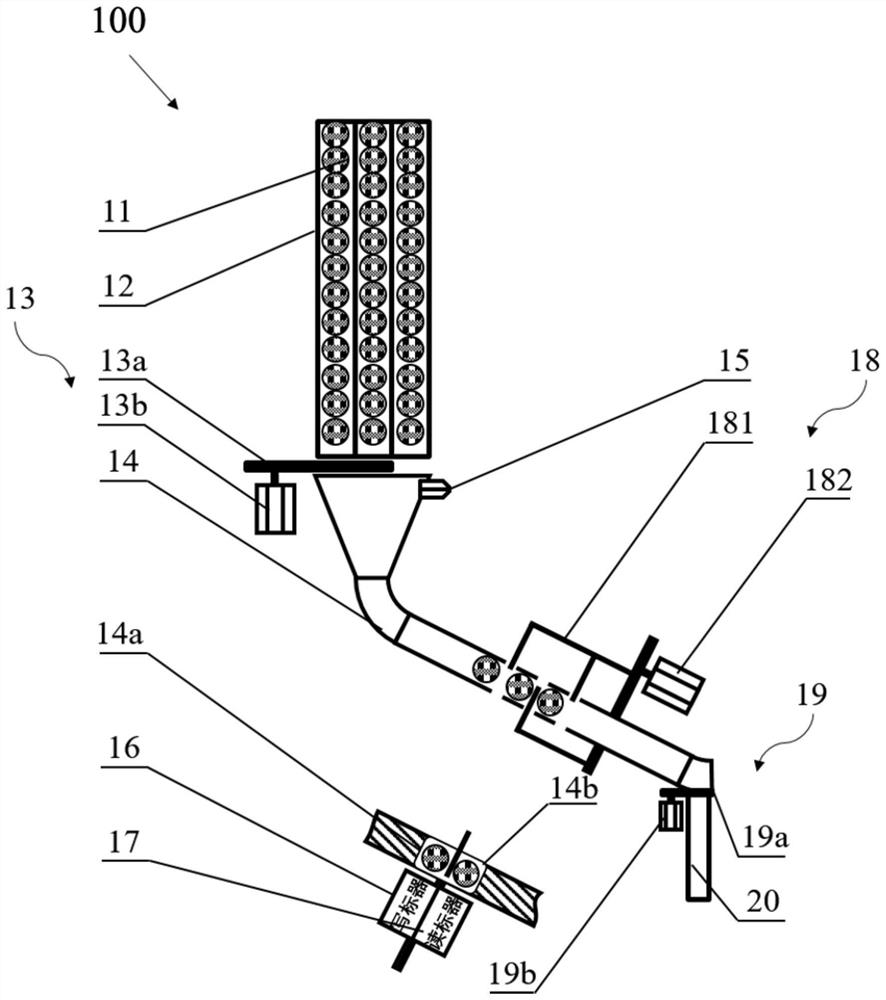

[0046] Coal belt bidding machine 100 includes a plurality of spherical radio frequency tags 11, a tag bin 12, a label delivery mechanism 13, a label slidew...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com