Draught fan of extractor hood and extractor hood

A range hood, fan technology, applied in the direction of removing oil fume, machines/engines, mechanical equipment, etc., can solve the problems of difficult exhaust air, poor oil fume suction effect, etc., and achieve the effect of enhancing suction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

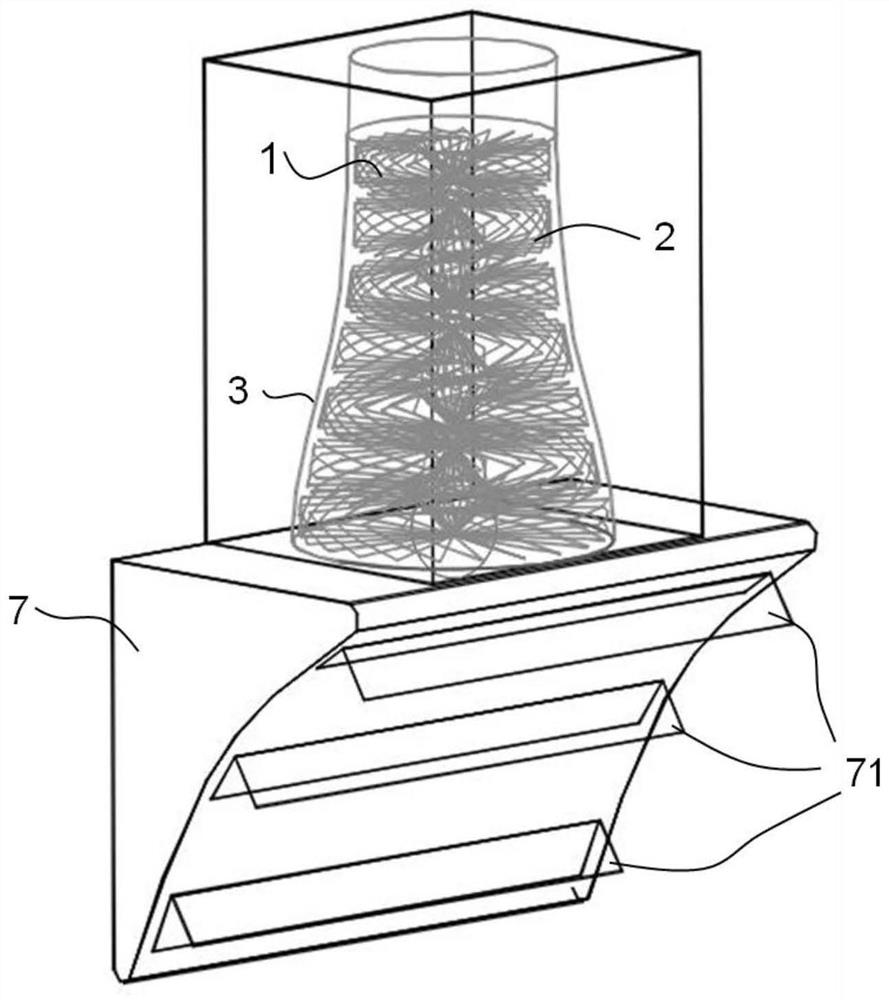

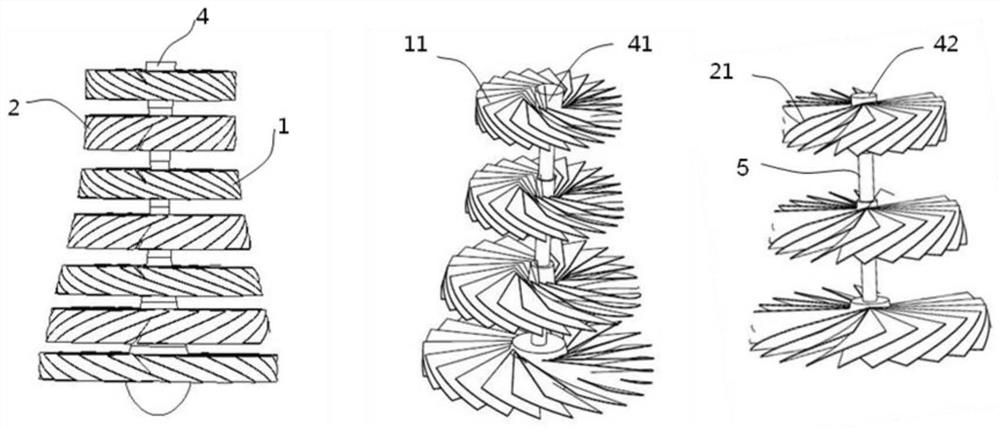

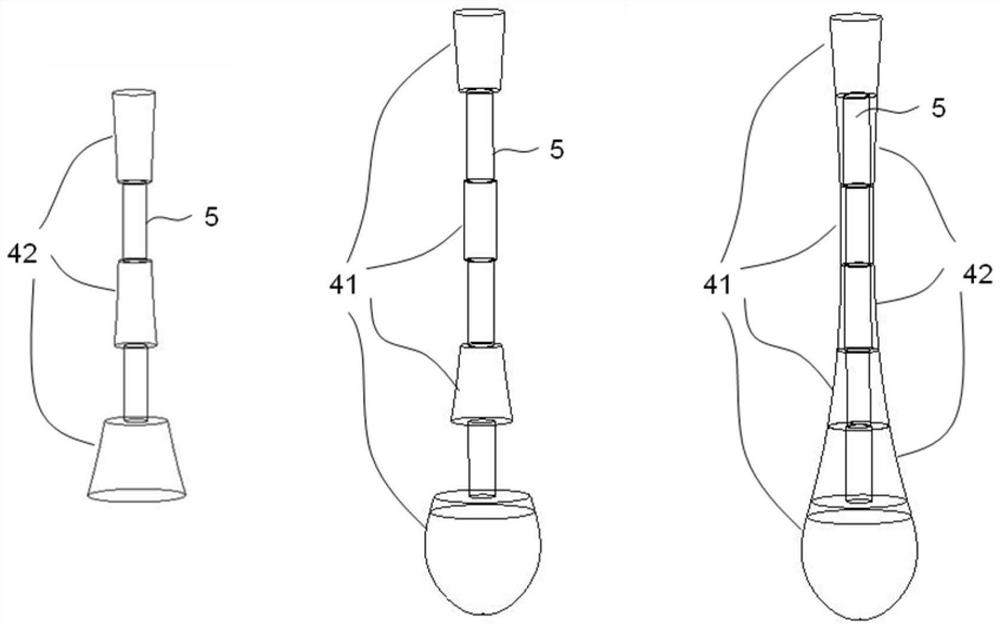

[0024] Embodiment 1 of the present invention provides a fan for a range hood, such as figure 1 and 2 As shown, it includes the impeller assembly and the fan volute 3, the impeller assembly includes the forward impeller 1 and the reverse impeller 2, the forward impeller 1 is composed of a plurality of forward rotating impeller blades 11, and the reverse impeller 2 is composed of a plurality of reverse rotating impeller blades 21. The forward impeller 1 and the reverse impeller 2 are coaxially arranged at intervals and rotate in opposite directions.

[0025] In this way, when the fan is working, the forward impeller 1 and the reverse impeller 2 rotate at the same time, so that the airflow pressure is recursively pushed inside the fan volute 3, and the internal static pressure of the fan can be quickly increased layer by layer within the shortest distance, and the oil fume is continuously generated. The strong suction greatly enhances the oil fume suction effect.

[0026] The f...

Embodiment 2

[0035] Embodiment 2 of the present invention provides a range hood, which includes a smoke collection hood 7 and a fan of the range hood provided in Embodiment 1. The smoke collection hood 7 is provided with three air intake holes 71, and the range hood The blower fan is installed on the fume collecting hood 7 tops.

[0036] The air intake hole 71 comprises an upper air intake hole, a middle air intake hole and a lower air intake hole, the lower air intake hole has the largest width, the middle air intake hole width is next, and the upper air intake hole has the smallest width. The lower air intake hole has the largest width and large air intake volume, which can ensure that the rising oil fume can be sucked in as soon as the airflow starts to rise, reducing the diffusion of oil fume; the upper air intake hole has a small width and large negative pressure, which can ensure that the rising oil fume is diffused The fume is sucked in. By setting different air intake widths, it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com