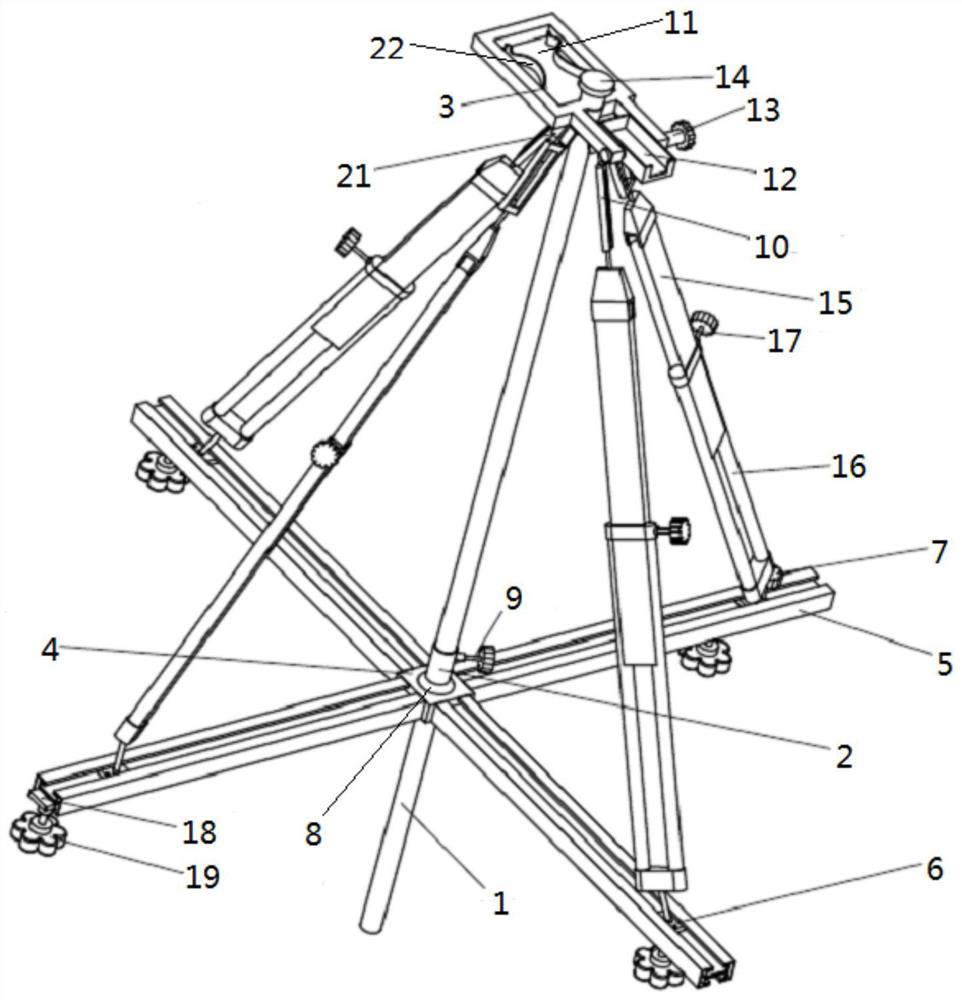

Spherical tank pre-weldment setting-out device and construction method thereof

A pre-welding, spherical tank technology, applied in instruments, measuring instruments, active optical measuring devices, etc., can solve the problems of unorthodox construction process, too large deviation of lofting accuracy, and difficulty of lofting, etc., to achieve simple structure and reduce accuracy. The effect of low cost and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

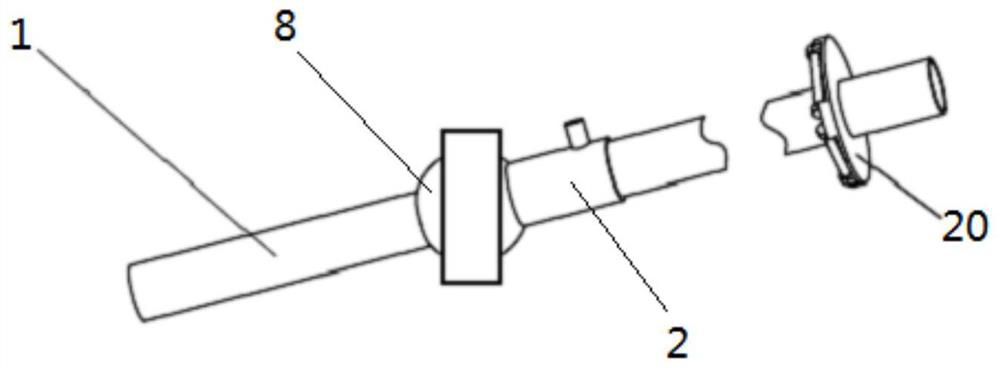

[0036] A construction method for lofting pre-welded parts of a spherical tank, comprising the following steps:

[0037] S1. Fixing of the setter: fix the setter at the manhole of the spherical tank through the positioning slider of the base;

[0038] S2. Adjustment of the lofting device: adjust the height and level of the lofting device through the height adjustment mechanism;

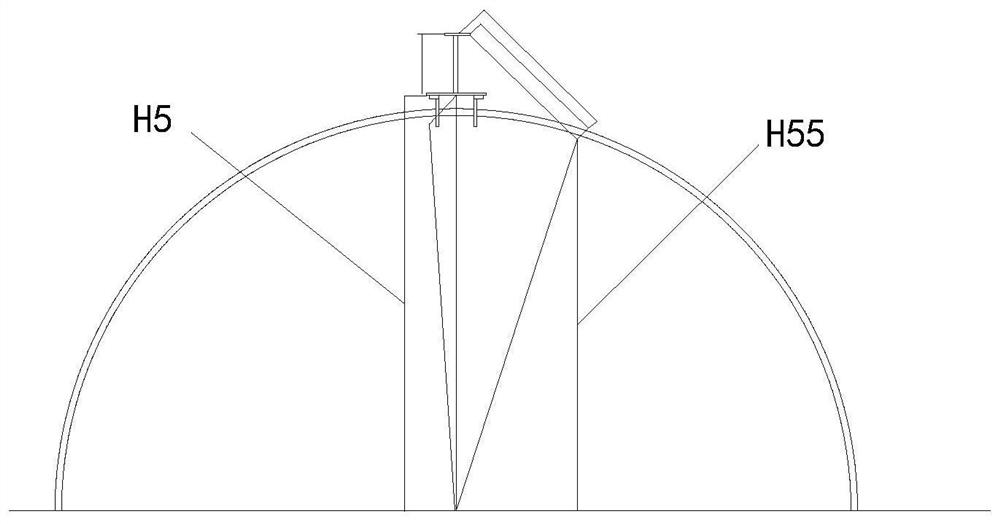

[0039] S3. Data measurement: measure the required data H1 and H4;

[0040] S4. Data calculation: Calculate according to the stakeout radius and stakeout formula, and adjust the angle of the laser rangefinder on the stakeout device so that the data displayed on the rangefinder is consistent with the calculation structure; when the volume of the spherical tank>1000m3 and the outer diameter of the manhole flange When it is not greater than 1000mm, it can be considered approximately that H2≈H4, and this procedure can be skipped; when the volume of the spherical tank is ≤1000m3, this procedure cannot be ig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com