Red mud desalted sea sand AC-16 asphalt mixture and preparation method thereof

A technology of asphalt mixture and sea sand, which is applied in the field of building materials, can solve the problems of low utilization rate, inability to alleviate the heavy burden of red mud, and low added value of products, so as to achieve convenient material acquisition, environmental protection and land occupation problems, and improve utilization value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] First, desalinated sea sand is produced by the following process.

[0032] Specifically, the purchased sea sand is piled up; the sea sand that is piled up is desalinated, that is, washed with water, dried, and passed through a 2.36mm sieve to obtain sea sand with a particle size range of 0-2mm; the obtained sea sand The mass percentages passing through the following sieves are shown in Table 2.

[0033]

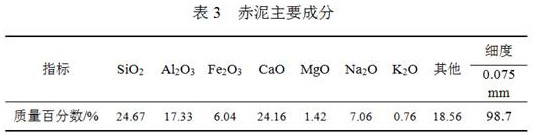

[0034] Then, the red mud with the indicators listed in Table 3 is used.

[0035]

[0036] The asphalt used is 70#A grade road asphalt, with a penetration of 73 (0.1mm), a softening point of 50°C, and a ductility of 116cm at 15°C.

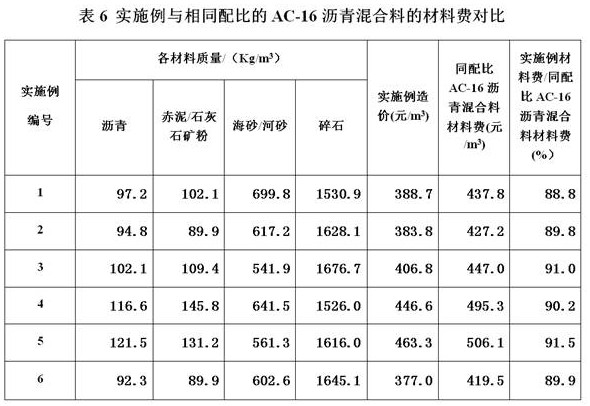

[0037] The 1# gravel (particle size 10mm-20mm), 2# gravel (particle size 5mm-10mm) and 3# gravel (particle size 2mm-5mm) used are all limestone gravel, and the apparent density is 2.722g in turn. / cm 3 , 2.729g / cm 3 : 2.697g / cm 3 , and its grading range is shown in Table 1.

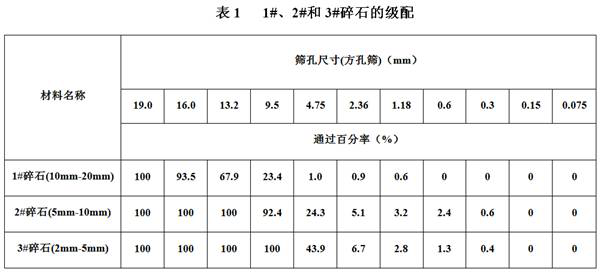

[0038] Finally, according to the mass percentage, take 4...

Embodiment 2

[0041] The performance of each raw material used in Example 2 is consistent with that described in Example 1. The difference between Example 2 and Example 1 is that the mass percentage of each raw material component used in this example is 3.7% red mud, 25.4% of desalinated sea sand with particle size of 0-2mm, 15.3% of 3# crushed stone, 13.6% of 2# crushed stone, 38.1% of 1# crushed stone; Mix #crushed stone, 2# crushed stone and 1# crushed stone evenly, and heat to 165°C to prepare the mixed material;

[0042] In order to verify the road performance of the above mixed material, the optimal asphalt ratio was determined by Marshall compaction test, and 70#A grade road with a mass percentage of 3.9% and a temperature of 155-160°C was added to the prepared mixed material The asphalt was mixed to obtain the desalinated red mud sea sand AC-16 asphalt mixture, and the same measurement method as in Example 1 was used to measure the red mud desalinated sea sand AC-16 asphalt mixture ...

Embodiment 3

[0044] The performance of each raw material used in Example 3 is consistent with that described in Example 1. The difference between Example 3 and Example 1 is that the mass percentage of each raw material component used in this example is 4.5% red mud, 22.3% of desalinated sea sand with a particle size of 0-2mm, 17.3% of 3# crushed stone, 10.1% of 2# crushed stone, 41.6% of 1# crushed stone; Mix #crushed stone, 2# crushed stone and 1# crushed stone evenly, and heat to 165°C to prepare the mixed material;

[0045] In order to verify the road performance of the above mixture, the optimum asphalt content (4.2%) determined by the Marshall compaction test was added to the mixture prepared above with 70# A-grade road asphalt was mixed to obtain red mud desalinated sea sand AC-16 asphalt mixture, and the red mud desalinated sea sand AC-16 asphalt mixture of the present embodiment was measured by the same measurement method as in Example 1. The measurement results are shown in Table...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com