Plant essence extraction process

A plant essence and extraction technology, applied in the field of plant essence extraction technology, can solve the problems of insufficient plant extrusion, waste of cost, pollution of plant essence, etc., and achieve the effect of improving the degree of chopping, avoiding insufficient extrusion and easy to produce juice.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

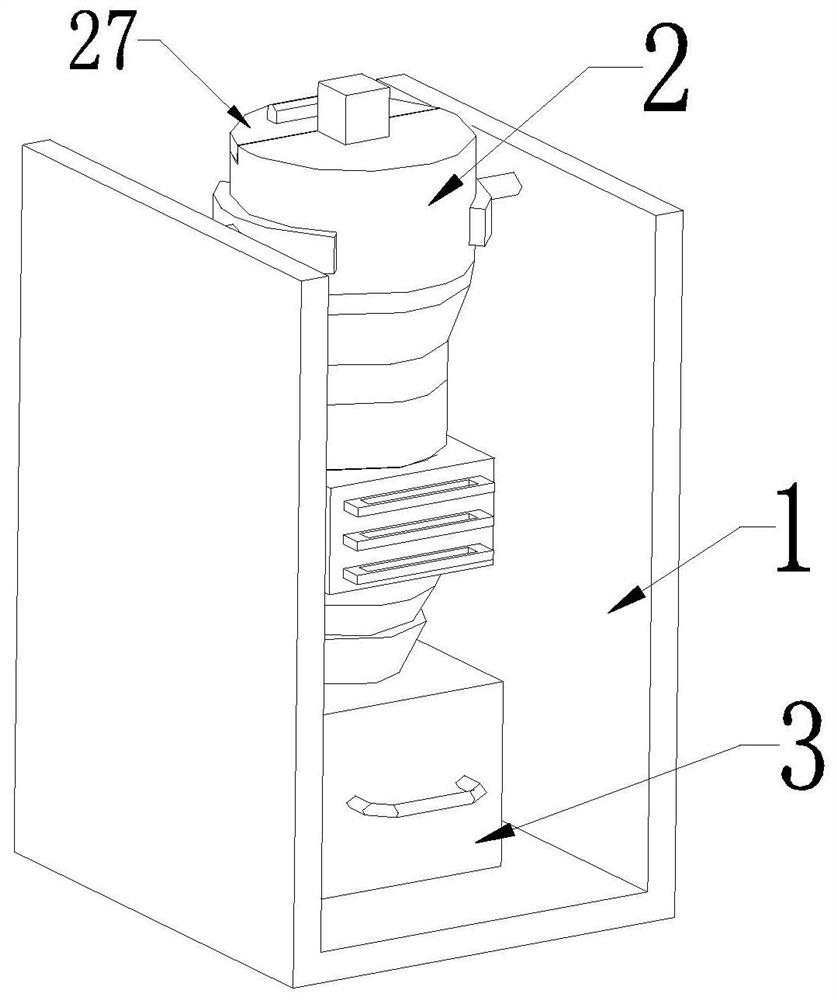

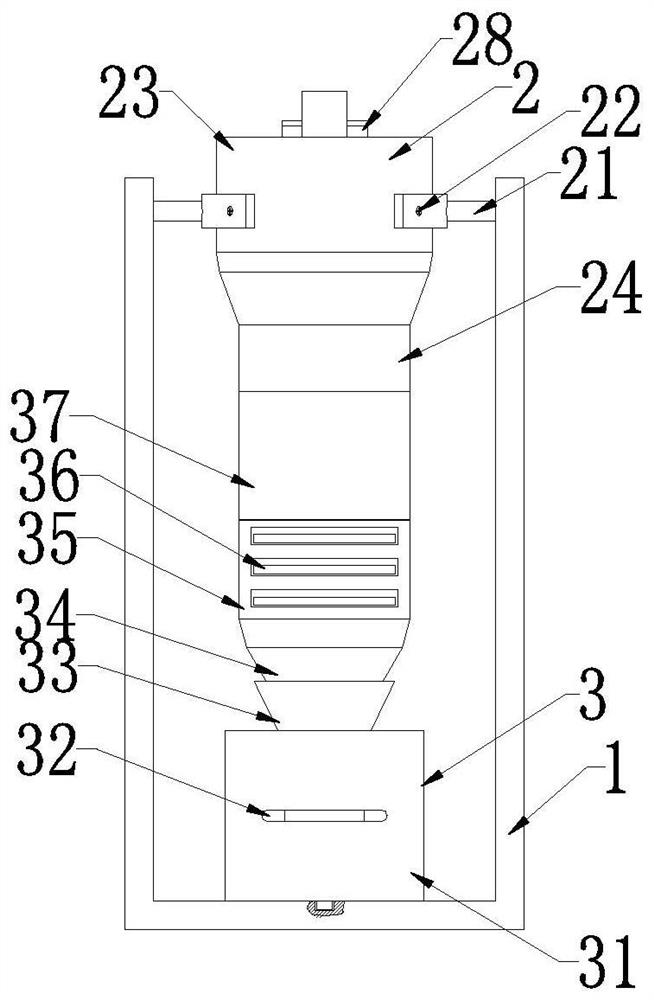

[0032] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

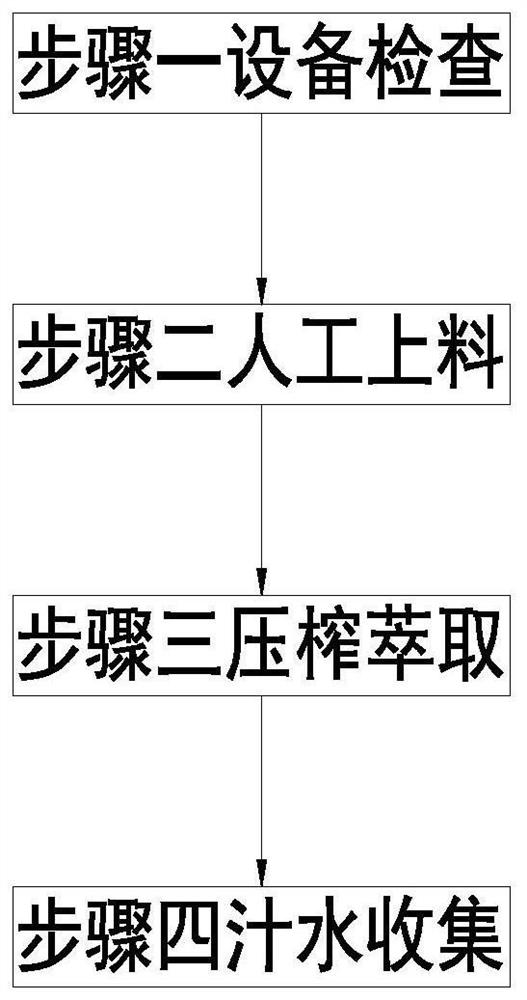

[0033] Such as Figure 1 to Figure 9 As shown, a plant essence extraction process mainly includes the following steps:

[0034] Step 1: Equipment inspection: check the operation of the equipment before using the plant extractor to press extract the plant essence;

[0035] Step 2: Manual feeding: Manually place the fresh plants that need to be squeezed into the cutting tank 23, and the cutting tank 23 works to cut off the fresh plants, so as to achieve the purpose of manual feeding;

[0036] Step 3: Squeeze extraction: After completing the manual feeding operation in step 2, the chopped plants enter the squeeze box 37 through the sedimentation box 24, and then the squeeze box 37 works to squeeze the juice out of the fresh plants, thereby completing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com