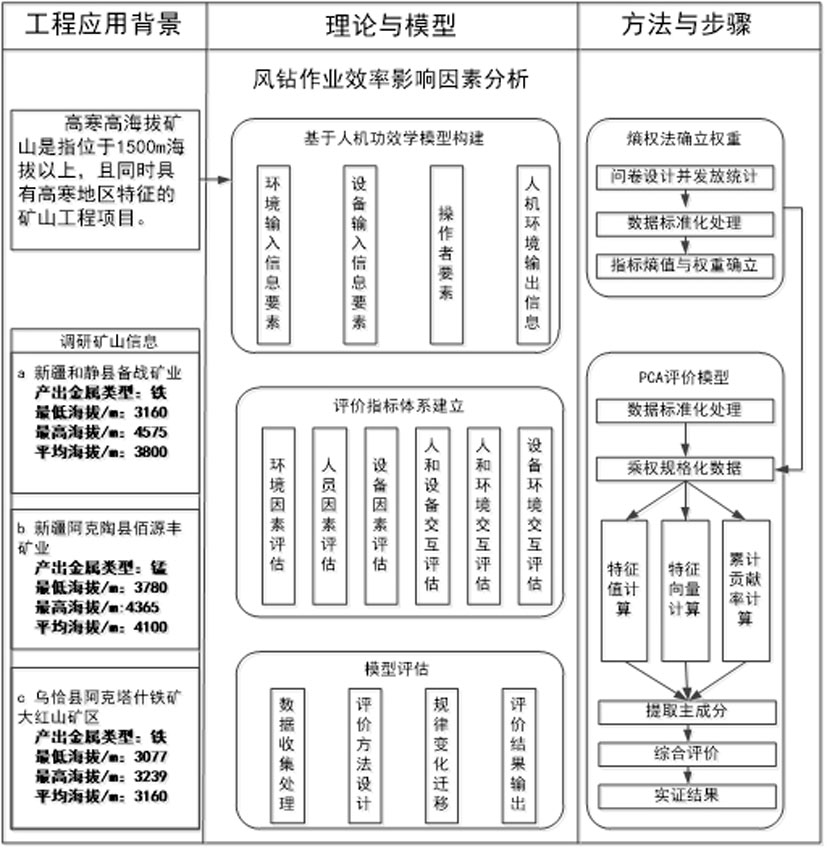

Evaluation method of influencing factors of pneumatic drilling operation efficiency in high-altitude alpine metal mine mining

An efficiency influencing factor and metal mine technology, which is applied in the field of evaluation of factors influencing the efficiency of pneumatic drilling operations in high-altitude and alpine metal mine mining, so as to avoid human disturbance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Embodiment 1: The evaluation method of the influencing factors of the pneumatic drilling operation efficiency in the high-altitude alpine metal mine mining is carried out according to the following steps:

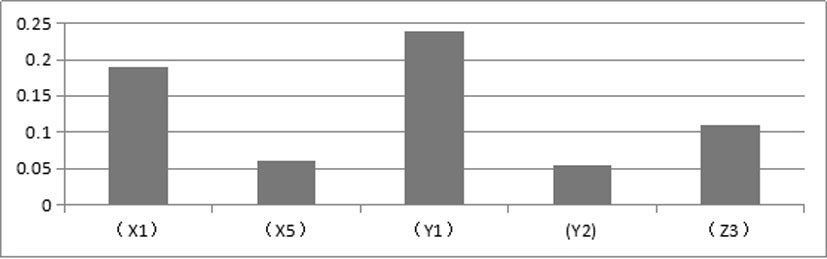

[0069] The first step is to collect personnel index data, equipment index data and environmental index data. The personnel index data includes age (X1), working years (X2), education level (X3), physical and psychological fatigue (X4) and degree of acclimatization ( X5) five indicators, the equipment index data include the output power of the diesel engine (Y1), the load and energy consumption of the wind drilling rig (Y2) and the aging and wear rate of the wind drilling rig (Y3), and the environmental index data include the altitude (Z1 ), temperature (Z2), humidity (Z3), oxygen content (Z4), atmospheric pressure (Z5), air velocity (Z6), vibration (Z7), lighting (Z8) and noise (Z9) nine indicators;

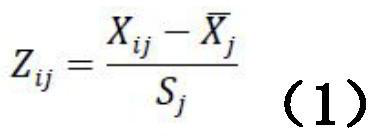

[0070] In the second step, in order to eliminate the impact of the...

Embodiment 2

[0109] Embodiment 2: as the optimization of above-mentioned embodiment, this index of educational level (X3) adopts Cauchy function formula (15) to carry out assignment quantification to it before carrying out the standardized processing described in the second step of embodiment 1,

[0110]

[0111] In the formula, α, β, a, b are undetermined parameters, and c is a basically acceptable grade value in the grade. The parameters can be determined: α=4.8003, β=0.7798, a=0.5371, b=-0.0451. Finally, determine the quantization value of each level: f(1)=0.01, f(2)=0.2367, f(3)=0.5066, f(4)=0.7, f(5)=0.8193, f(6)=0.9173 , f(7)=1.

Embodiment 3

[0112] Embodiment 3: as the optimization of above-mentioned embodiment, this index of the output power (Y1) of diesel engine is before carrying out the standardization process described in the second step of embodiment 1, the output power (Y1) of diesel engine is calculated by formula (16),

[0113]

[0114] In the formula (16): η is the output power of the diesel engine; Nm is the mechanical loss power of the internal combustion engine, kW; Ni is the indicated power of the internal combustion engine, kW; Ne is the effective power of the internal combustion engine, kW; wherein, the calculation of Nm is as formula (17),

[0115]

[0116] In the formula (17): ε is the compression ratio; Vm is the average speed of the piston, m / s; Vh is the working volume of the cylinder, L; τ is the number of strokes; n is the speed, r / min; i is the number of cylinders, Ne Calculated as formula (18),

[0117]

[0118] In formula (18): ne is the effective thermal efficiency, which refers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com