Congou black tea dynamic shaping fermentation process and processing method

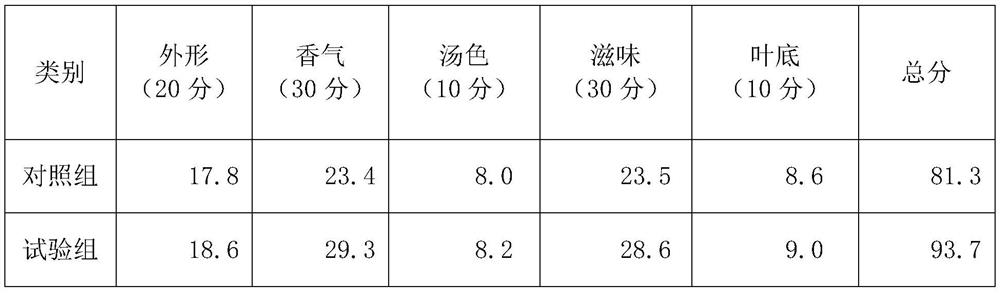

A technology for Gongfu black tea and fermentation process, which is applied in the field of dynamic shaping fermentation technology and processing of Gongfu black tea, can solve the problems of single aroma type, insufficient taste richness and low overall quality of Gongfu black tea, and achieves tight shape, fine color and luster. The effect of black and oily, red and bright under the leaves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] After fresh leaves are plucked, start to process within 4 hours, at first carry out withering, wither for 12 hours, spread leaf thickness 10cm, after withering, the water content of tealeaves is 65%, and leaf surface loses luster.

[0022] Put the withered leaves into the kneading machine kneading barrel for dynamic shape fermentation. The temperature is 29°C and the relative humidity is 82%. The amount of withered leaves is 80% of the capacity of the kneading bucket. The barrel speed is 10r / min, kneading for 45min; the kneading barrel speed is 115r / min, kneading for 45min; the kneading barrel speed is 120r / min, kneading for 40min; the kneading barrel speed is 125r / min, kneading for 40min; Add medium pressure and knead for 15 minutes, reduce pressure and knead for 10 minutes, and empty knead for 15 minutes. After the dynamic shaping fermentation process is over, 75% of the fermented tea leaves turn red, 25% show brass color, and the strip yield is over 95%.

[0023] Pu...

Embodiment 2

[0027] After fresh leaves are plucked, start to process within 4 hours, at first carry out withering, wither for 13 hours, spread leaf thickness 8cm, after withering, the water content of tealeaves is 66%, and leaf surface loses luster.

[0028] Put the withered leaves into the kneading barrel of the kneading machine for dynamic shape fermentation. The temperature is 30°C and the relative humidity is 70%. The amount of withered leaves is 80% of the capacity of the kneading bucket. The barrel speed is 10r / min, kneading for 47min; the kneading barrel speed is 115r / min, kneading for 47min; the kneading barrel speed is 120r / min, kneading for 42min; the kneading barrel speed is 125r / min, kneading for 38min; Add medium pressure and knead for 13 minutes, reduce pressure and knead for 8 minutes, and empty knead for 15 minutes. After the dynamic shaping fermentation process is over, 75% of the fermented tea leaves turn red, 25% show brass color, and the sliver yield is 97%.

[0029] P...

Embodiment 3

[0033] After fresh leaves are plucked, start to process within 4 hours, at first carry out withering, wither for 12 hours, spread leaf thickness 12cm, after withering, the water content of tealeaves is 64%, and leaf surface loses luster.

[0034] Put the withered leaves into the kneading machine kneading barrel for dynamic shape fermentation. The temperature is 28°C and the relative humidity is 85%. The amount of withered leaves is 80% of the capacity of the kneading bucket. The barrel speed is 10r / min, kneading for 44min; the kneading barrel speed is 115r / min, kneading for 43min; the kneading barrel speed is 120r / min, kneading for 38min; the kneading barrel speed is 125r / min, kneading for 42min; Add medium pressure and knead for 13 minutes, reduce pressure and knead for 12 minutes, and empty knead for 15 minutes. After the dynamic shaping fermentation process is over, 75% of the fermented tea leaves turn red, 25% show brass color, and the bar forming rate is 99%.

[0035] Pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com