A quick demoulding terminal machine suitable for automatic processing

A terminal machine and demoulding technology, applied in the direction of line/collector parts, electrical components, connections, etc., can solve problems such as unfavorable automatic assembly line production, and achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

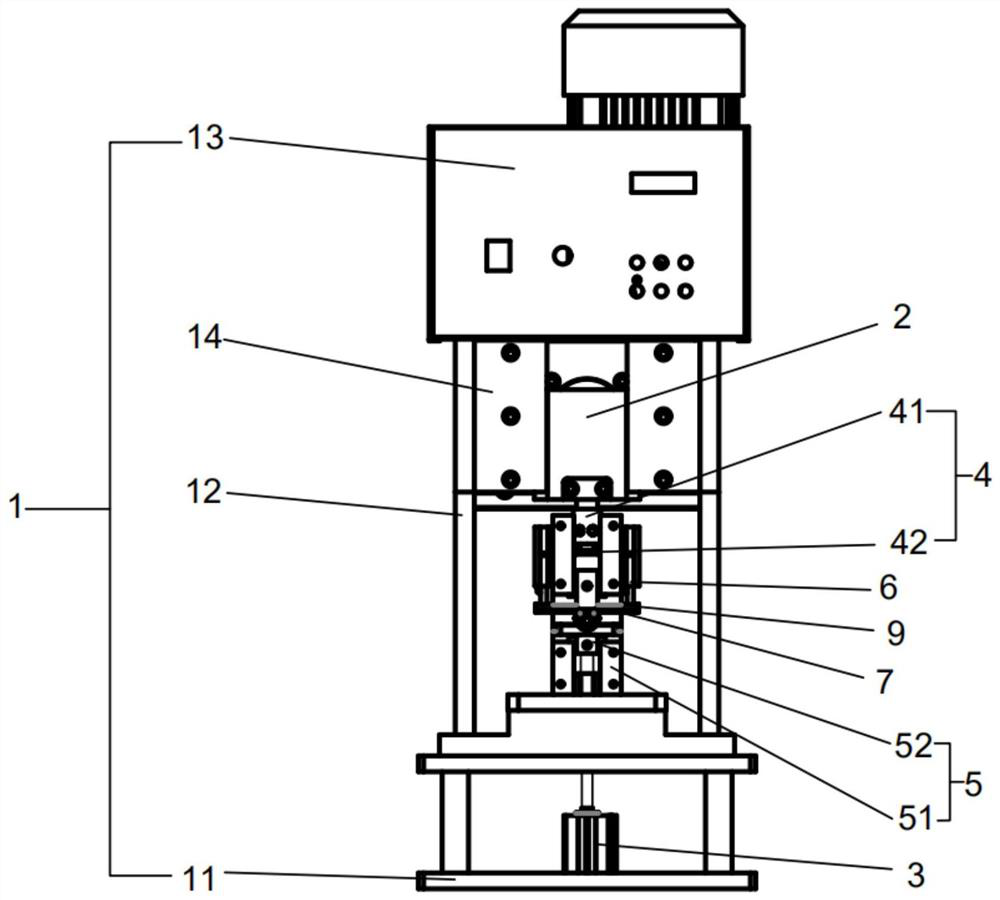

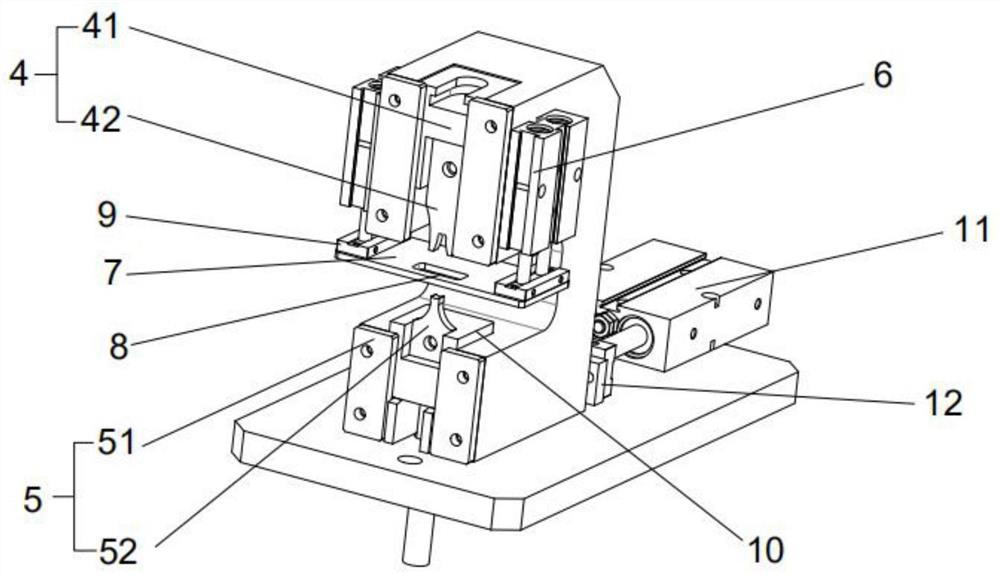

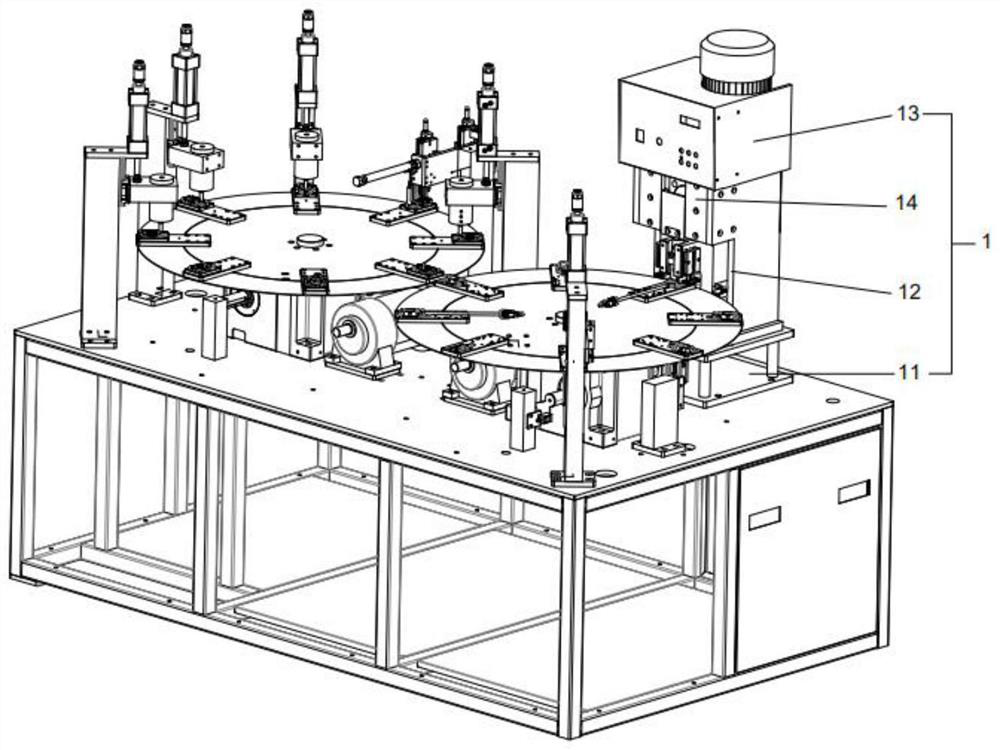

[0025] Embodiment 1: A quick demoulding terminal machine suitable for automatic processing, including a frame 1 and a terminal die installed in the frame 1, the terminal die includes an upper mold 4 and a lower mold 5, and the frame 1 It includes a bottom plate 11, a vertical frame 12 installed on the bottom plate 11, and a power control assembly 13 installed on the top surface of the vertical frame 12. An auxiliary clamping mounting frame 14 is installed on the upper end of the vertical frame 12, and the auxiliary clamping installation A downward pressure cylinder 2 is installed in the frame 14, a demoulding cylinder 3 is installed on the base plate 11, and the downward pressure cylinder 2 and the demoulding cylinder 3 are coaxially arranged;

[0026] The upper formwork 4 includes an upper formwork base 41 fixed on the auxiliary installation clamping frame and a traveling cutter head 42 longitudinally slidably connected to the upper formwork base 41, and the traveling cutter h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com