Rotary waterproof button lock

A rotary and push-button technology, which is applied in the field of aircraft flap locks, can solve problems that cannot meet the requirements of military products, large operating space and opening size, and weak load-bearing capacity, and achieve fast, reliable, and good unlocking and locking operations. Aerodynamic shape, the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The principles and features of the present invention are described below in conjunction with examples, which are only used to explain the present invention and are not intended to limit the scope of the present invention.

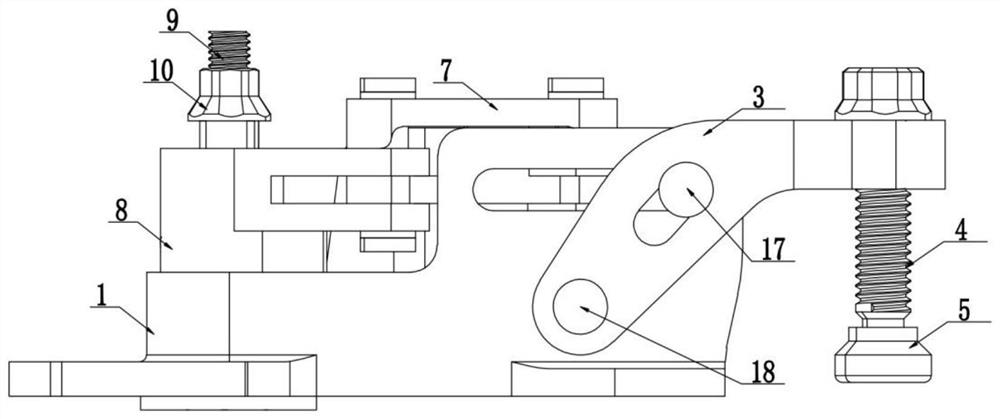

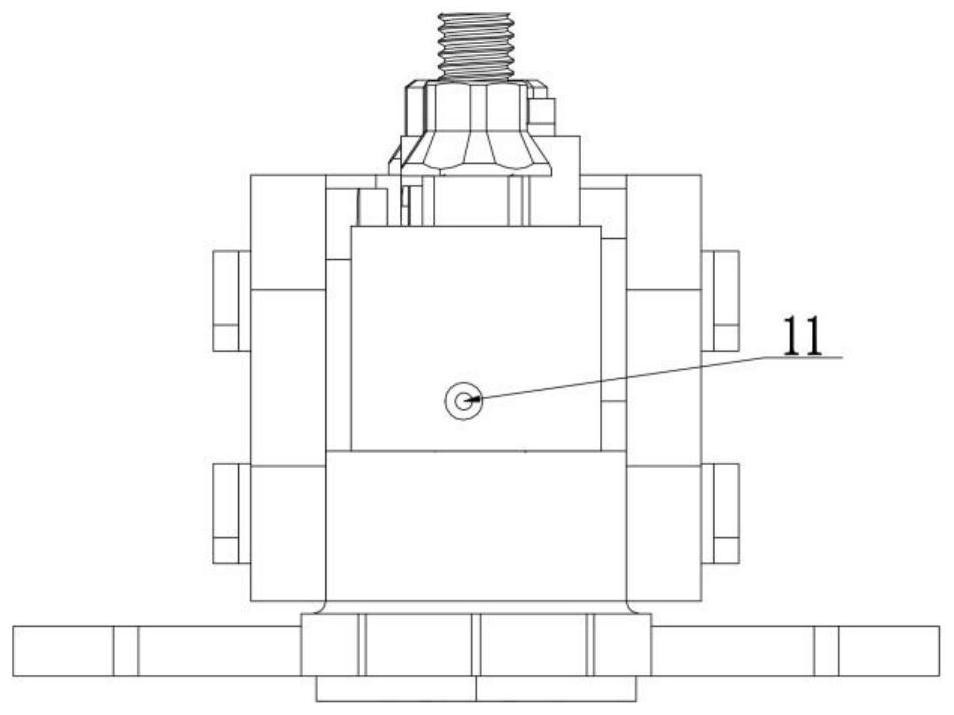

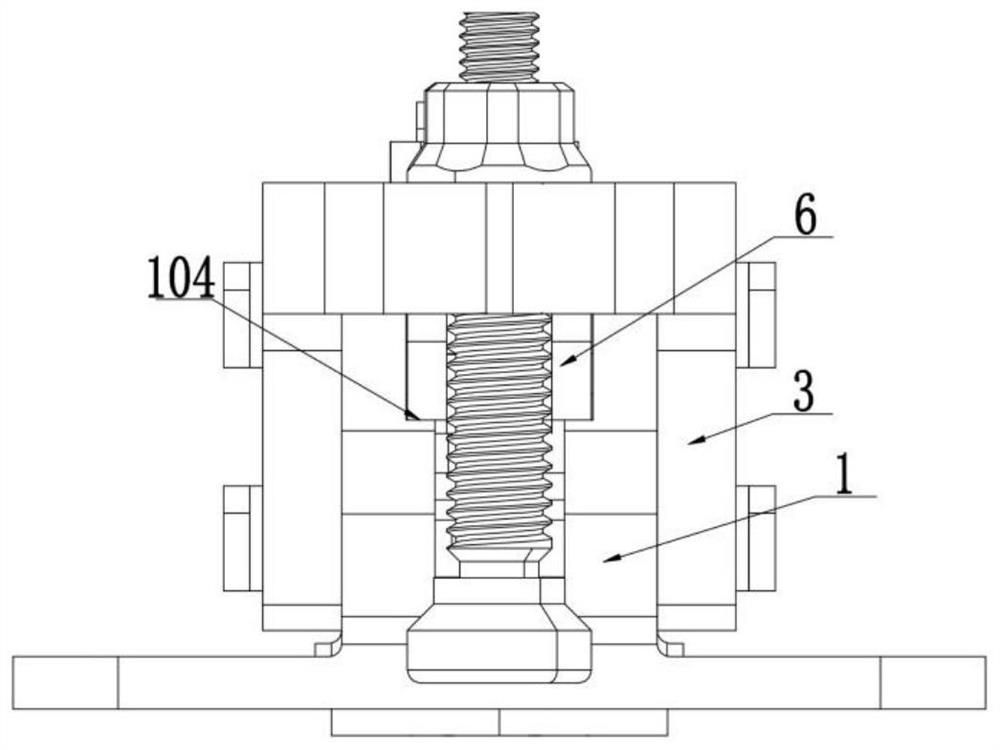

[0053] Such as Figure 1-Figure 23 As shown, a rotary waterproof button lock includes a lock base 1, a drive assembly, a swing arm 8, a slider 6, a support 3 and a pressure head. One side of the lock base 1 is provided with a drive jack 101, and the other side There is a chute 102 on it, the drive assembly includes a shaft housing 2 and a push rod 9 inserted in the shaft housing, the shaft housing is sleeved in the drive socket, and the shaft housing 2 is provided with A through groove 201, the push rod 9 is provided with a pin shaft 15, the pin shaft extends into the through groove, a spring 12 is provided on the push rod below the pin shaft, and a spring 12 is provided on the lock seat. A locking groove 103 adapted to the end of the pin;

[0054]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com