Construction method for double-wall steel suspension cofferdam of main bridge bearing platform of super-large bridge

A construction method and technology for extra-large bridges, which are applied in excavation, bridges, bridge parts, etc., can solve the problems of difficulty in ensuring the quality of cofferdam assembly and welding and high construction difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] The invention provides a construction method for a double-walled steel suspension box cofferdam of a main bridge cap of a super-large bridge. The cofferdam construction method includes the following steps:

[0073] Step S1, install the steel casing on the river bed, level the river bed, install the supporting corbel above the water surface of the steel casing, assemble the bottom keel and bottom plate of the cofferdam on the supporting corbel, and lay the bottom slab above the bottom keel; Assemble the bottom panel of the cofferdam above the periphery of the keel.

[0074] Step S2, install the cofferdam lowering system and floor hanging system on the steel casing, the lowering system is connected to the bottom section wall, the floor hanging system passes through the bottom plate and connects with the bottom keel, and the cofferdam is lowered to a self-floating state. Concrete is poured into the compartment of the cofferdam, and the cofferdam is lowered to a self-floati...

Embodiment 2

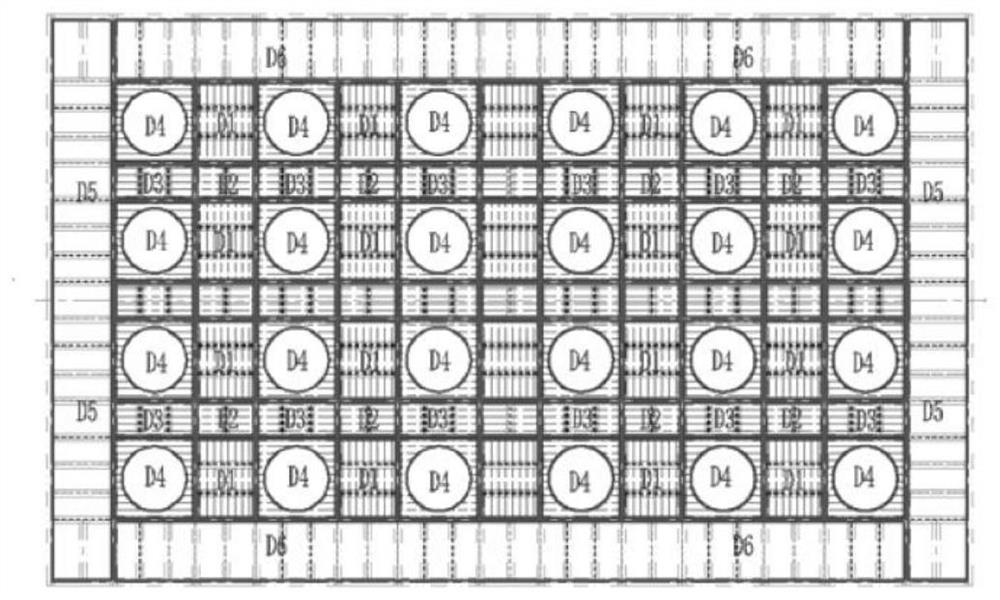

[0081] According to specific embodiments of the present invention, such as Figure 1-18 As shown, the present invention provides a double-walled steel hanging box cofferdam construction method for the main bridge cap of a super-large bridge; the main bridge of this super-large bridge is constructed in the Huaihe River channel, and the river bed of the Huaihe River at the construction position has large undulations and deep water depth. The construction method for the double-wall steel hanging box cofferdam of the super-large bridge main bridge; wherein, the double-wall steel hanging box cofferdam can be composed of the bottom keel 20, the bottom plate distribution beam, the bottom plate, the inner and outer wall steel plates (cofferdam side plates), The fully welded watertight structure composed of the support system in the wall, the compartment partition in the wall, the hoop stiffening plate, and the inner support has an outer plane size of 38.2m×23.2m, and the distance from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com