Method for transporting and erecting precast beam on steep slope of bridge-tunnel connected section of alpine valley region

A prefabricated beam and canyon technology, applied in the erection/assembly of bridges, bridges, bridge construction, etc., can solve problems such as transportation difficulties, and achieve the effects of reducing safety risks, facilitating construction, and slowing longitudinal slopes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods.

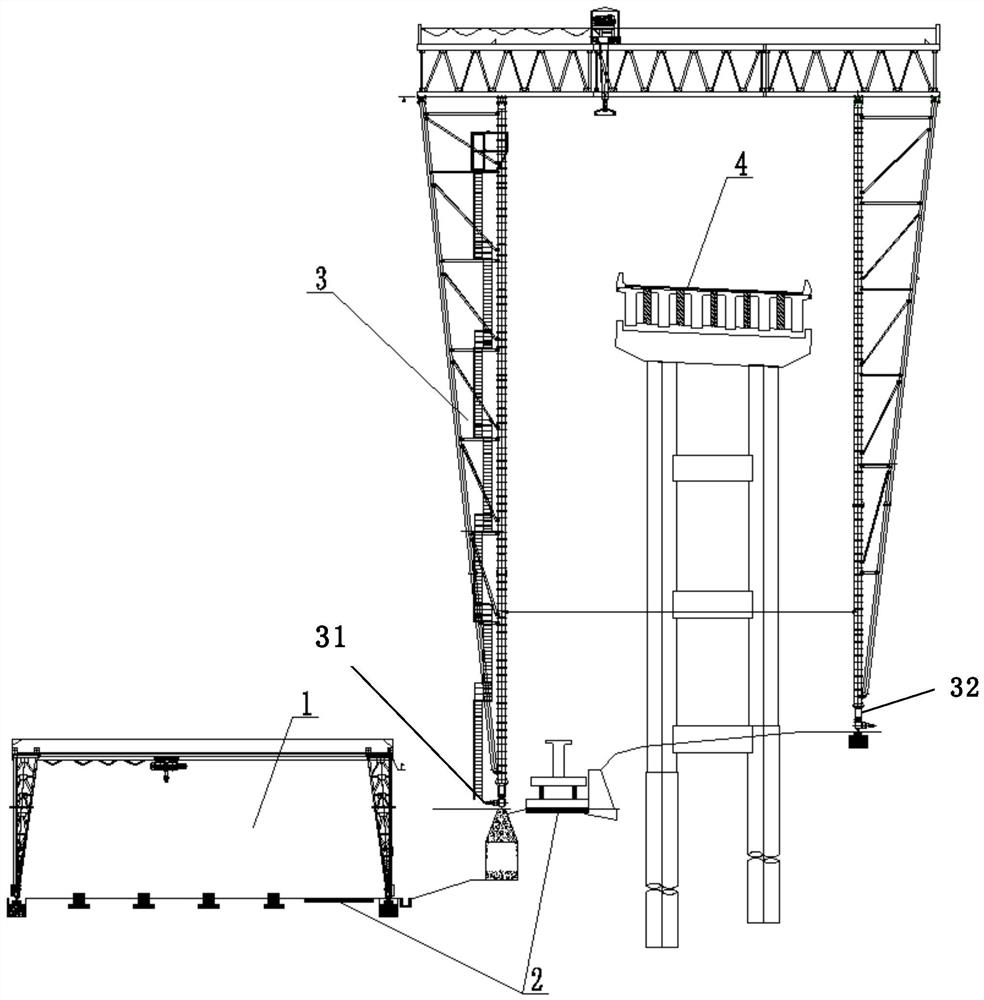

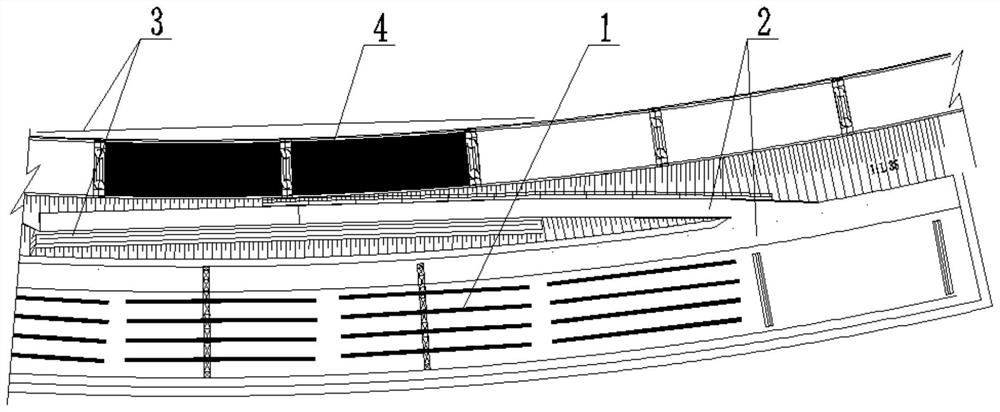

[0031] Such as Figure 5 As shown, in the method for transporting and erecting prefabricated beams on the steep slope of the bridge-tunnel connecting section in the mountains and canyons of the present invention, the following processes are specifically included: beam field layout, prefabricated beam production, beam transportation road layout, special beam lifting machine layout, prefabricated beam transportation, and beam lifting Erection, erection machine assembly, prefabricated girder erection.

[0032] Among them, such as figure 1 with figure 2 As shown, the beam field 1 is arranged on a relatively gentle slope near the side of the prefabricated beam to be erected. Preferably, the beam field 1 is arranged near the outer side of the precast beam to be erected, leaving a certain distance from the bridge to meet the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com