Degradable material

A technology for degrading materials and resins, applied in chemical instruments and methods, single-component polyester rayon, drilling compositions, etc., can solve the problems of temporary plugging agent waste and inability to effectively reach the target fracture area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

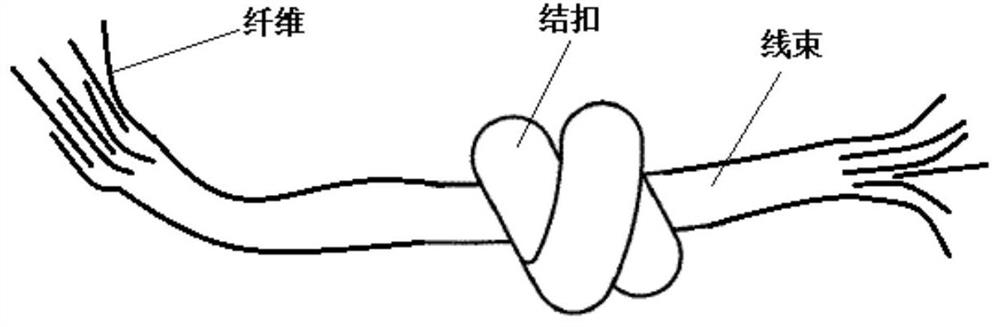

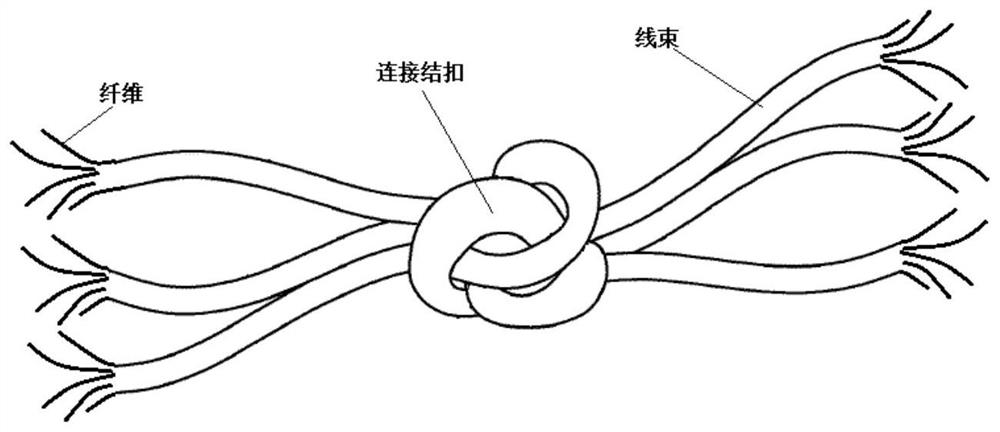

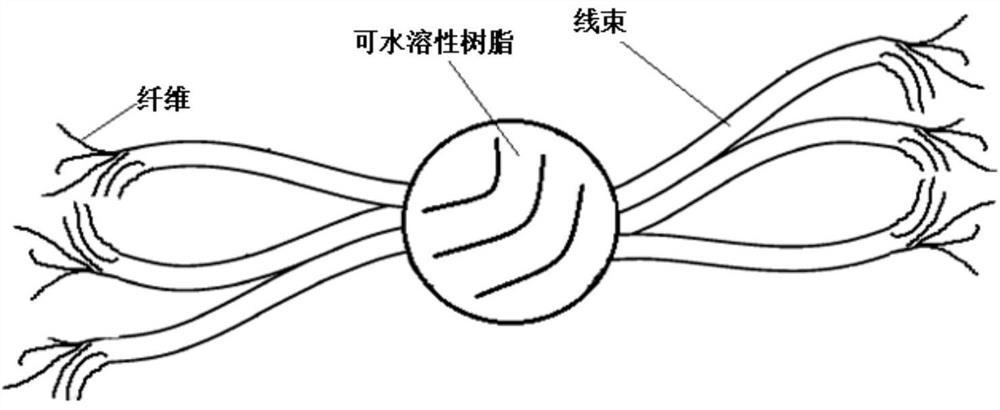

[0069] After extensive and in-depth research, the inventor has found that one or more bundles of fibers are twisted or braided to form a wire bundle, and the wire bundle is formed into a connecting knot or knot that protrudes outward relative to the wire bundle itself, which is beneficial to the original dispersion. The fibers are gathered together. Driven by the downhole fluid, the fibers move with the downhole fluid in units of wire bundles with prominent connecting knots or knots. When they move to the target fracture, the connecting knots or knots on the wire harness The target fractures can be sealed independently or overlapped with each other, which is conducive to the rapid formation of a sealing zone with a stable pressure bearing effect.

[0070] In addition, the structural design of connecting knots or knots can effectively prevent or avoid the fact that the fibers constituting the wire bundle are easily entangled and wound with each other during the actual pumping pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com