Milling Chatter Online Monitoring Method Based on Nonlinear Adaptive Decomposition and Shannon Entropy

A technology of milling chatter and Shannon entropy, applied in measuring/indicating equipment, metal processing equipment, metal processing mechanical parts, etc., can solve the problems of loss of nonlinear characteristics, complex algorithm parameter determination process, noise sensitivity, etc. Low degree, realize online monitoring, small calculation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

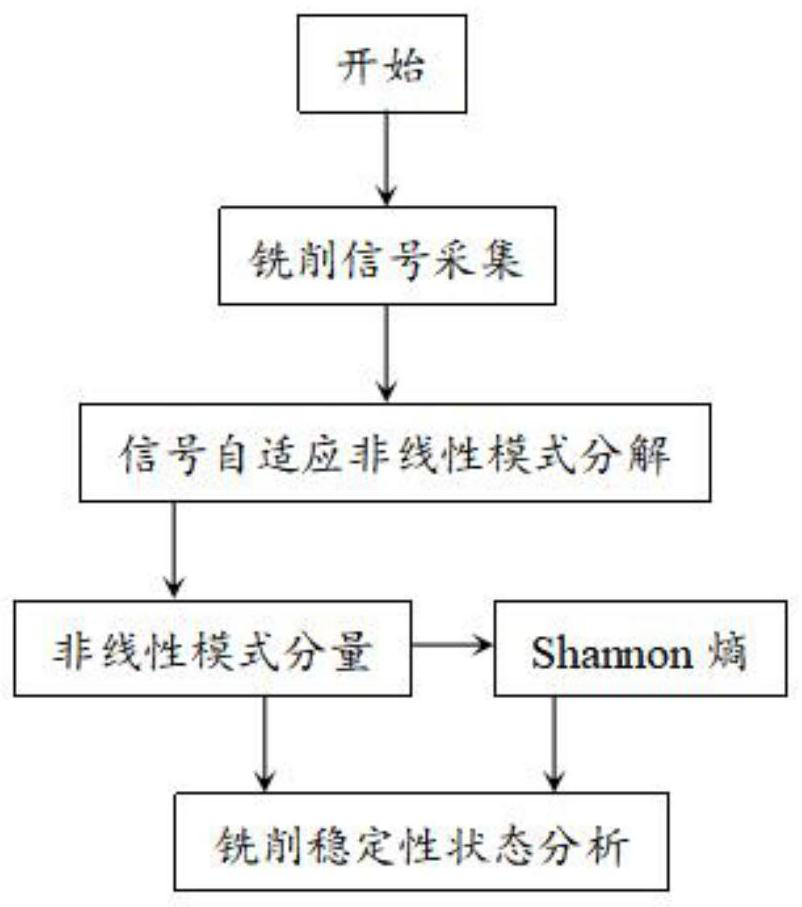

[0074] like figure 1 , the present invention is based on adaptive nonlinear mode decomposition and Shannon entropy milling chatter on-line monitoring method comprises the following steps:

[0075] (1) Milling signal acquisition

[0076] Collect the vibration signal of the spindle during the milling process through the accelerometer (model: PCB356A02) installed on the spindle end, denoted as X=[x 1 ,x 2 ,...,x n ], where n is the total length of the signal;

[0077] (2) Signal Adaptive Nonlinear Mode Decomposition

[0078] The nonlinear, non-stationary, multi-component signal model established in adaptive nonlinear mode decomposition is:

[0079]

[0080] Where K is the number of signal components, a i (t) and f i (t) is the instantaneous amplitude and instantaneous frequency of each component, θ i0 is the initial phase of each component, with a mean of 0 and a variance of σ 2 Gaussian white noise. In the adaptive decomposition process, the components with higher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com