Double-backfill type concrete vibrating rod capable of draining and refining

A technology of concrete and vibrating rods, which is applied in the processing of building materials, construction, building construction, etc. It can solve the problems of affecting the compactness of concrete and slow air discharge speed, so as to improve the vibrating effect, increase the compactness, and accelerate Effect of backfill rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

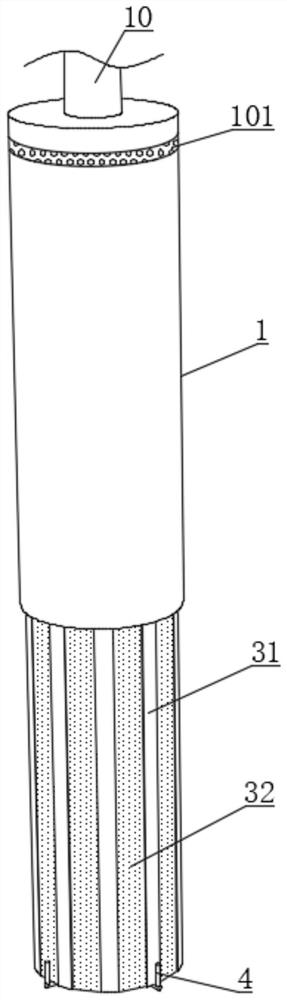

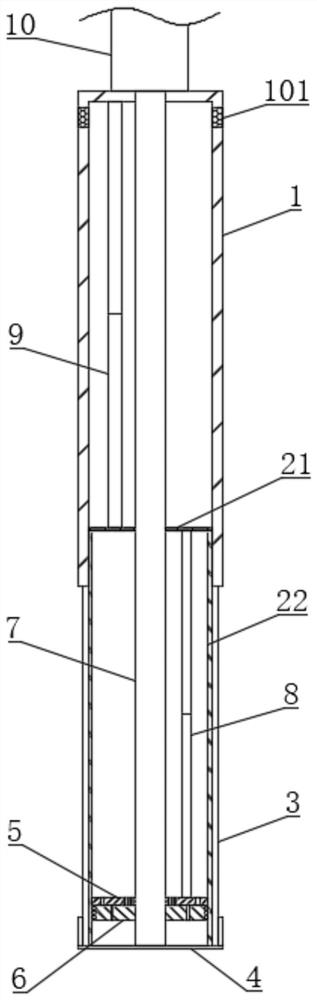

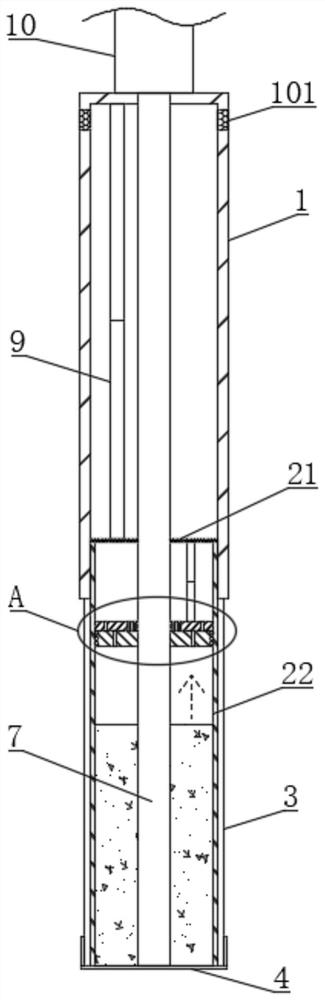

[0052] see figure 1 and figure 2 , a dual backfill concrete vibrator that can drain and refine, including a connecting pipe 10 connected to a vibrating device at one end, the other end of the connecting pipe 10 is fixedly connected with an outer cylinder 1, and the inner side of the outer cylinder 1 is provided with a vibrating The rod 7, the upper end of the vibrating rod 7 runs through the upper end of the outer cylinder 1 and is fixedly connected to the lower end of the connecting pipe 10. The inner cylinder of the outer cylinder 1 is slidably connected with an inner cylinder. The inner cylinder includes a mesh plate 21 and a straight cylinder 22. The mesh plate 21 is fixedly connected with The upper end of the straight cylinder 22 is provided with a through hole on the mesh plate 21, and the vibrating rod 7 passes through the through hole and is slidably connected to the inside of the through hole. A pair of electric telescopic rods 9 are fixedly connected between them. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com