Super-retarding efficient pumping agent and application thereof

A super-retarding and pumping agent technology, applied in the field of concrete admixtures, can solve the problems that retarding admixtures cannot meet the requirements and cannot affect the later strength and elongation of concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] According to weight percentage, the formula of the pumping agent is:

[0026] Aliphatic water reducer 30%,

[0027] Naphthalene superplasticizer 40%,

[0028] Technical grade white sugar 5%,

[0029] Sodium Tripolyphosphate 4%,

[0030] Technical Grade Sodium Gluconate 5.0%,

[0031] Aminotrimethylene phosphonic acid: 0.5%,

[0032] Air-entraining agent 0.1%,

[0033] 0.2% construction grade warm rubber,

[0034] Clear water 15.2%.

[0035] This formula is mainly used for the raw materials of the mixing station. The requirements of the concrete mixing station, the specific construction time is October, and the construction site is a drilled underground occlusal pile. The requirement is that the concrete retarding time is more than 65 hours for the initial setting and the final setting is less than 80 hours. And it has late strength, and the 28d strength is qualified.

Embodiment 2

[0037] According to weight percentage, the formula of the pumping agent is:

[0038] Naphthalene superplasticizer 20%,

[0039] Aliphatic water reducer 47%,

[0040] Technical Grade Sodium Gluconate 3%,

[0041] Sodium Tripolyphosphate 3%,

[0042] Industrial grade white sugar 3%,

[0043] Aminotrimethylenephosphonic acid: 1.0%,

[0044] Air-entraining agent 0.2%,

[0045] 0.2% construction grade warm rubber,

[0046] Clear water 22.6%.

[0047]This formula is used in concrete mixing plants. The specific construction time is March. The construction site is underwater occlusal piles. It is required that the concrete retarding time be greater than 60 hours for initial setting and less than 75 hours for final setting.

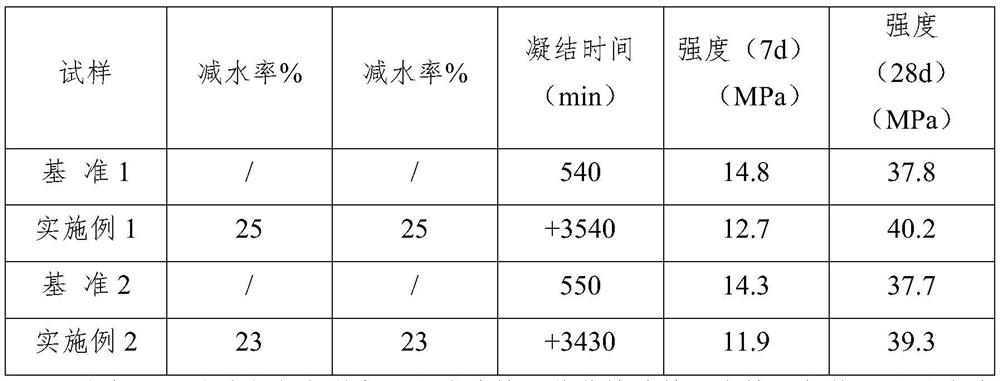

[0048] See Table 1-Table 3 for details about embodiment 1 and embodiment 2 concrete mix ratio and coagulation performance test

[0049] Table 1 Example 1 concrete mix ratio (unit: kg)

[0050] cement mineral powder fly ash natural sand pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com