Longitudinal beam placing tool

A tooling and longitudinal beam technology, applied in the field of longitudinal beam placement tooling, can solve the problem of single function of the placing rack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, further elaborate the present invention.

[0029] The orientations involved in this specification are all based on the orientation of a longitudinal beam placement tool of the present invention when it is in normal operation, and do not limit its orientation during storage and transportation. It only represents a relative positional relationship, not an absolute positional relationship.

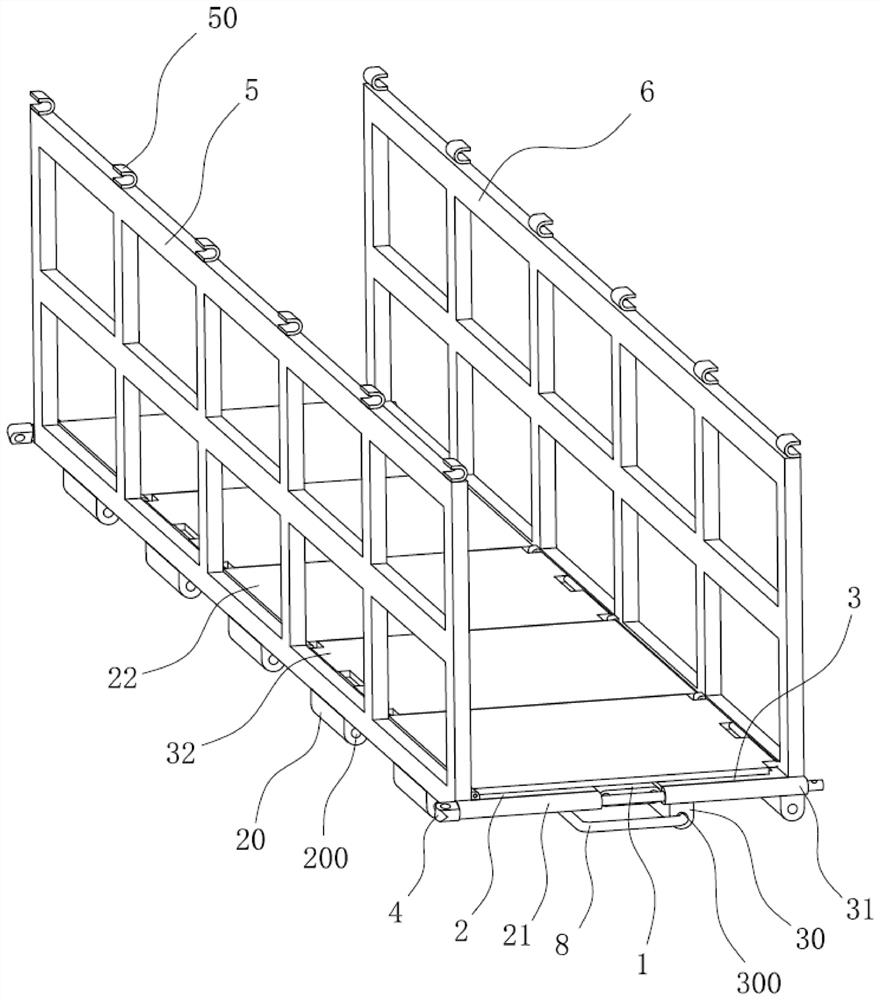

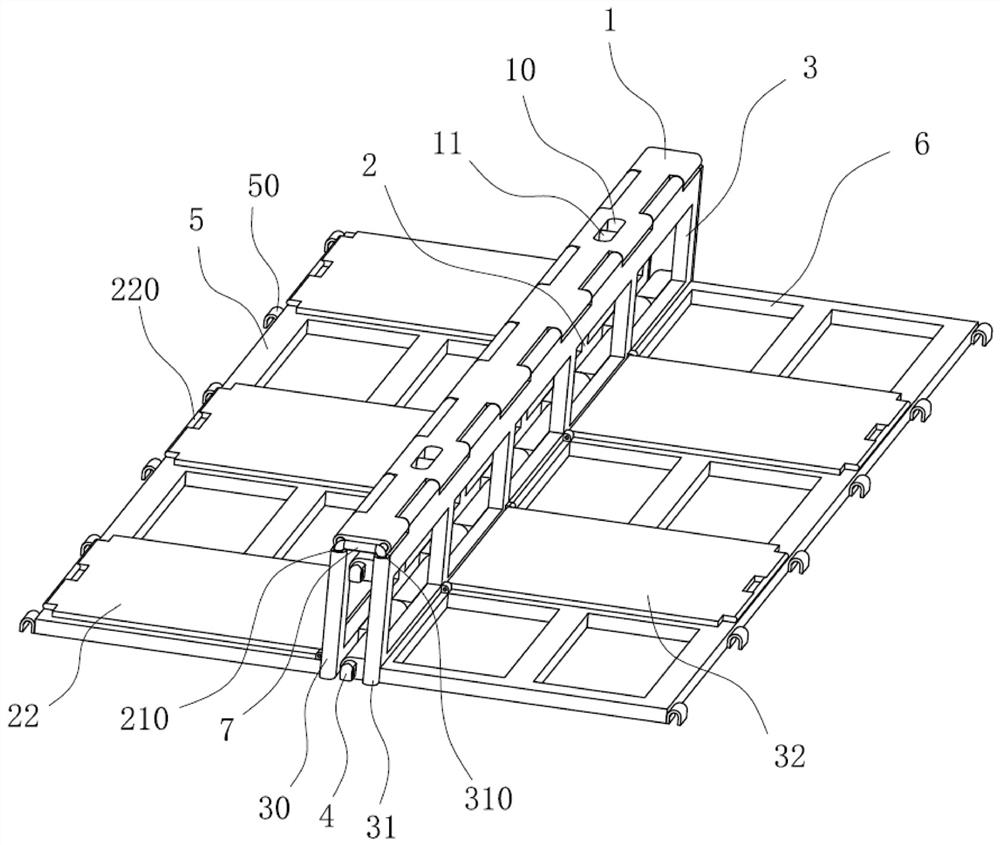

[0030] Such as figure 1 and figure 2 Commonly shown, the longitudinal beam tooling frame includes a connecting plate 1, a first plate body 2 and a second plate body 3 are symmetrically arranged on both sides of the connecting plate 1, and the connection plate 1, the first plate body 2 and the second plate body 3 The length direction is the same, the opposite side of the first plate body 2 and the connecting plate 1 is rotationally connected by the first rotating rod, the other side of the first plate body 2 is welded with the third plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com