A cell manufacturing process based on dry film formation

A dry film and cell technology, applied in sustainable manufacturing/processing, circuits, electrical components, etc., can solve problems such as affecting safety, burrs on the edge of electrodes, etc., to improve the efficiency and safety performance of finished products, equipment structure and The effect of cost reduction and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

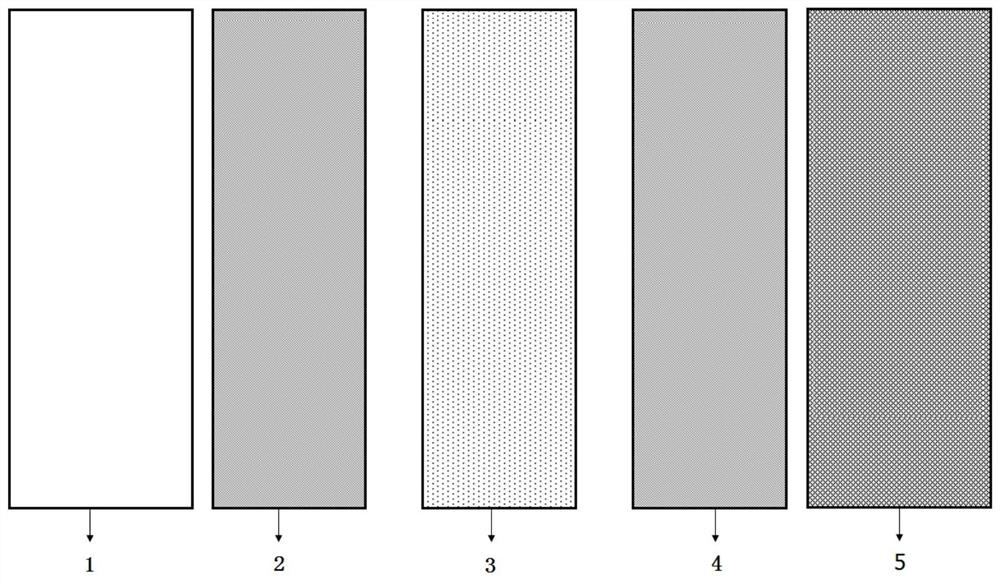

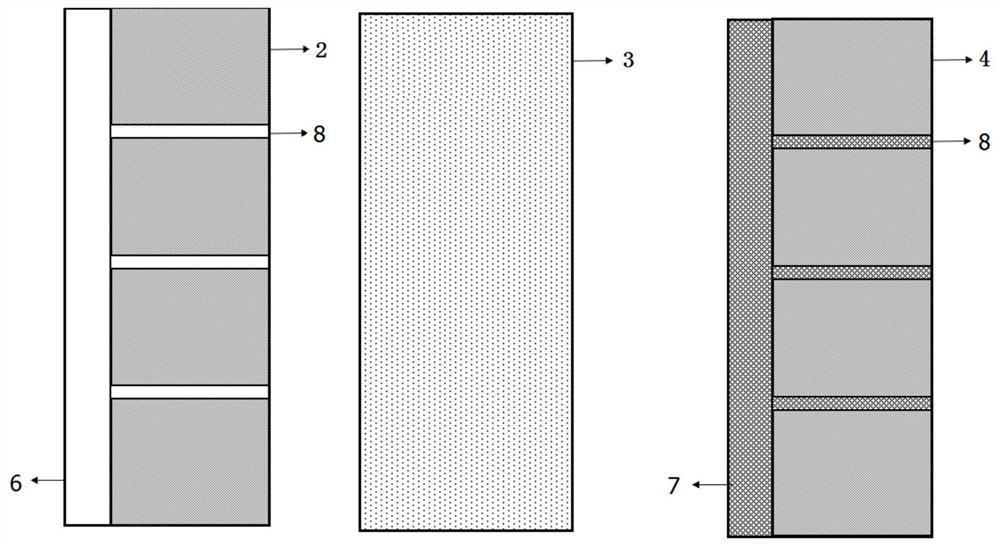

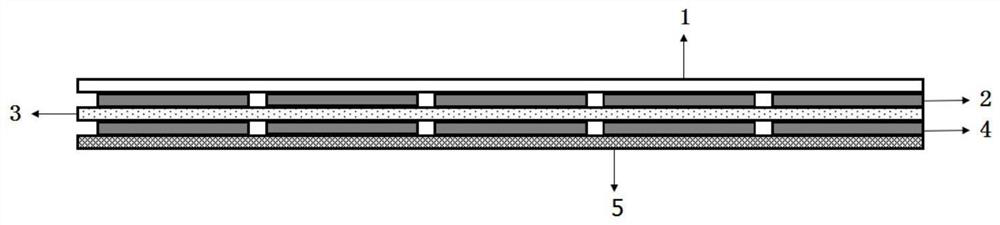

[0045] Firstly, the lithium iron phosphate, SUPER P and PTFE were fully mixed according to the mass ratio of 95:3:2 by dry method, and then rolled into a film to obtain a self-supporting positive electrode dry film. The mesophase carbon microspheres, SUPER P and PTFE According to the mass ratio of 95:3:2, they were fully mixed and rolled into a film to obtain a self-supporting negative electrode dry film, which was rolled to 100 μm respectively. The obtained self-supporting positive and negative electrode dry-process membranes were trimmed to a width of 40 cm, and then the self-supporting positive and negative electrode dry-process membranes were wound up separately.

[0046] The positive and negative current collectors used are aluminum foil and copper foil respectively. The thickness of the current collector is 10 μm respectively, and the width of the positive and negative electrode current collectors is greater than the width of the self-supporting dry film, so as to leave ...

Embodiment 2

[0051] Firstly, the ternary materials NCM, Ketjen black, and PVDF were fully mixed according to the mass ratio of 97:2:1 by dry method, and then rolled into a film to obtain a self-supporting positive dry film. Artificial graphite, Ketjen black, and PVDF were prepared according to The mass ratio of 97:2:1 was fully mixed and rolled into a film to obtain a self-supporting negative electrode dry film, which was rolled to 120 μm respectively. The obtained self-supporting positive and negative electrode dry-process films were trimmed to a width of 50 cm, and then the self-supporting positive and negative electrode dry-process films were wound up separately.

[0052] The positive and negative current collectors used are aluminum foil and copper foil respectively. The thickness of the current collector is 15 μm, and the width of the positive and negative current collectors is greater than the width of the positive and negative electrodes, so as to leave the tab part, such as figure...

Embodiment 3

[0057] Firstly, lithium cobalt oxide, KS6, and SBR were fully mixed according to the mass ratio of 90:7:3 by dry method, and then rolled into a film to obtain a self-supporting positive electrode dry film. Hard carbon, KS6, and SBR were mixed according to 90:7:3 The mass ratio is fully mixed and then rolled into a film to obtain a self-supporting negative electrode dry film, and rolled to 80 μm respectively. The obtained self-supporting positive and negative electrode dry-process membranes were trimmed to a width of 60 cm, and then the self-supporting positive and negative electrode dry-process membranes were wound up separately.

[0058] The positive and negative current collectors used are aluminum foil and copper foil respectively. The thickness of the current collector is 20 μm respectively, and the width of the positive and negative current collectors is greater than the width of the positive and negative electrodes, so as to leave the tab part, such as figure 1 shown. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com