Installation structure and installation method for steel structure canopy to penetrate through hidden frame glass curtain wall

A technology of hidden frame glass curtain wall and installation structure, applied in the direction of wall, building components, building structure, etc., can solve the problems of easy damage to the appearance effect of hidden frame glass curtain wall, construction difficulties, etc., to achieve easy appearance, easy installation, and avoid damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

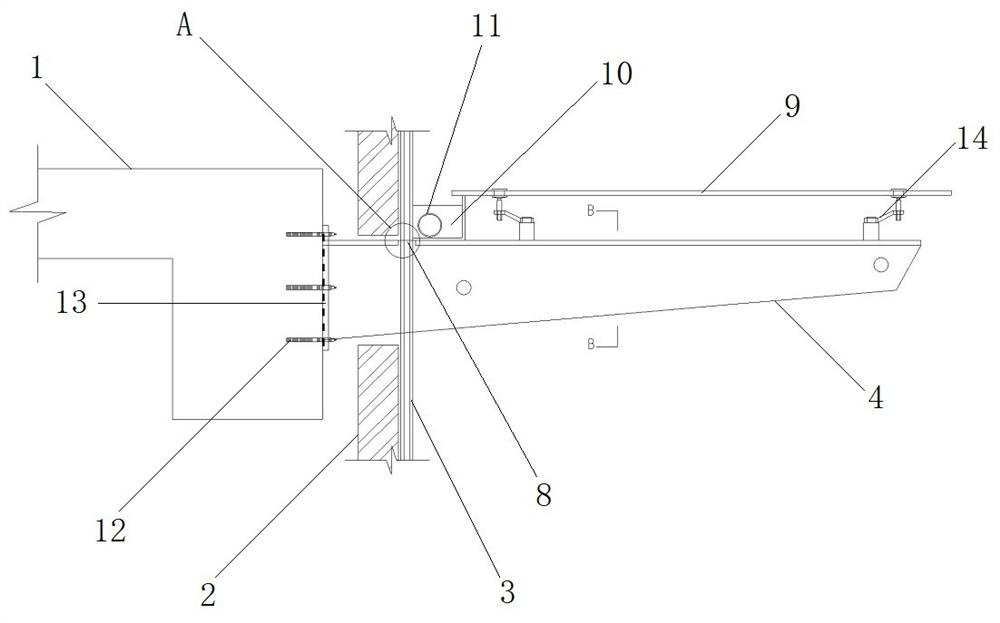

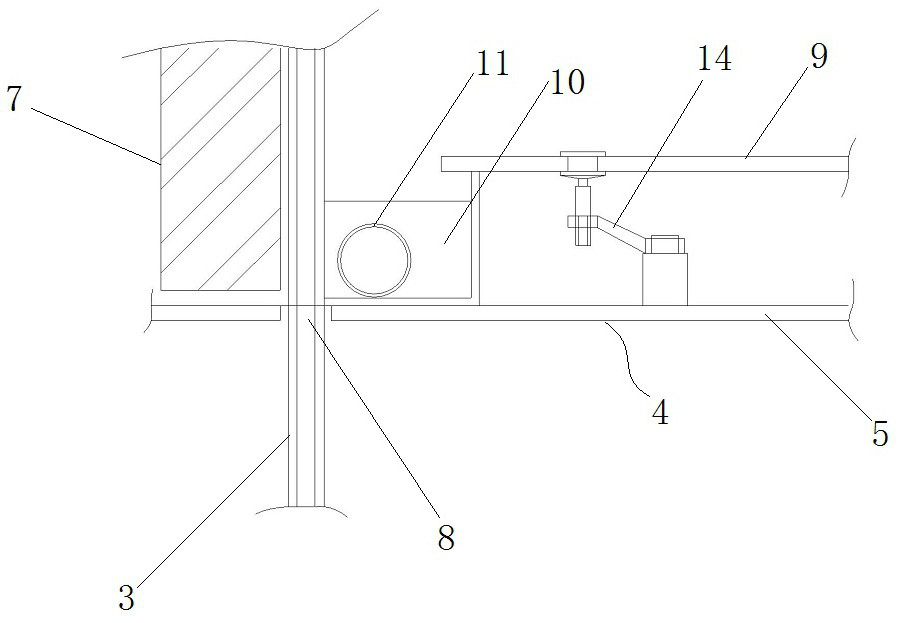

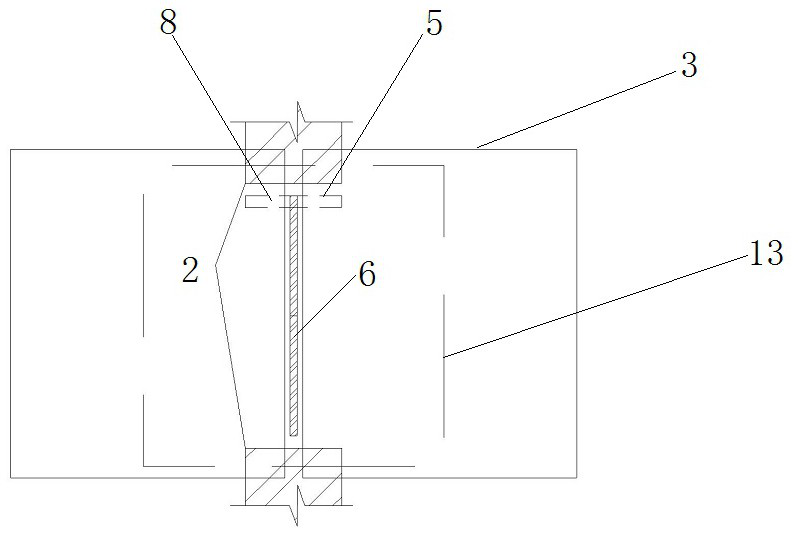

[0034] Such as figure 1 , figure 2 and image 3 As shown, the installation structure of the steel structure canopy through the hidden frame glass curtain wall includes the wall panel 1 on the building, the aluminum alloy glass curtain wall frame 2 fixedly installed on the wall panel 1, and the glass curtain wall frame 2 bonded to the glass curtain wall frame 2 with structural adhesive. Curtain wall glass 3 and the steel structure canopy connected to the glass curtain wall.

[0035] Specifically, the glass curtain wall frame 2 includes a plurality of vertical keels 7 and horizontal keels welded together. The vertical keels 7 and the horizontal keels are arranged so that the glass curtain wall frame forms a grid structure, and the curtain wall glass 3 is installed in each grid. .

[0036] The steel structure canopy includes a plurality of T-shaped canopy steel beams 4 arranged side by side and at intervals, each T-shaped canopy steel beam 4 corresponds to a vertical keel 7, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com