Ink heat preservation stirring kettle

A stirring tank and ink technology, applied in the direction of mixer accessories, dissolving, mixing machines, etc., can solve the problems of uneven mixing of materials, poor stirring effect, and reduced stirring effect, etc., to achieve convenient use, good practicability, and good independence Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

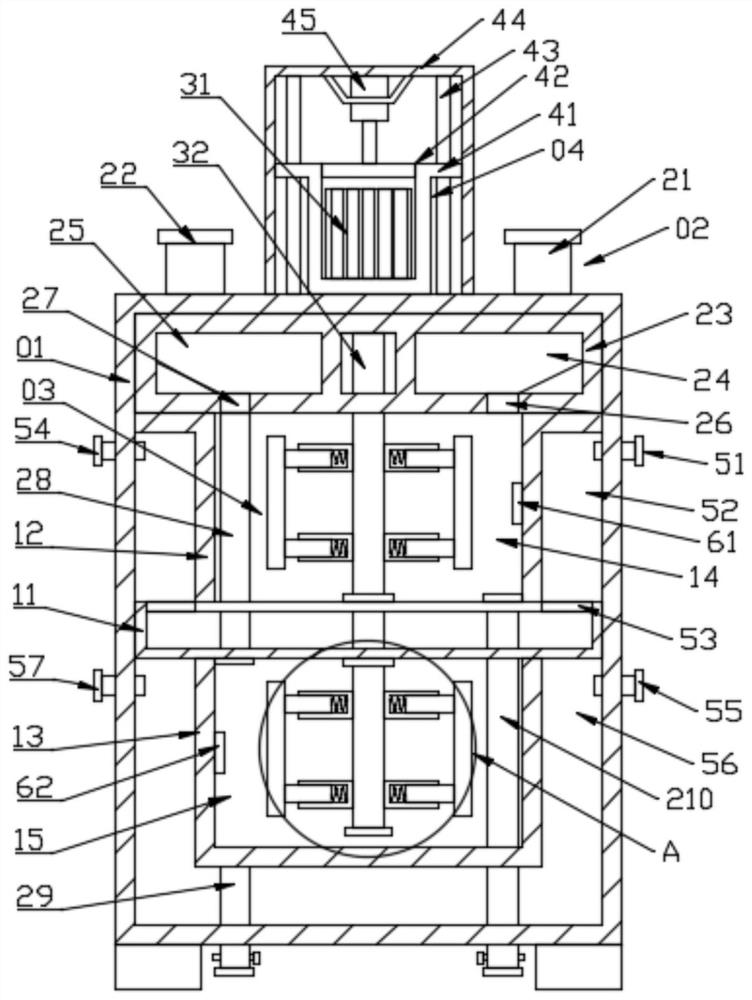

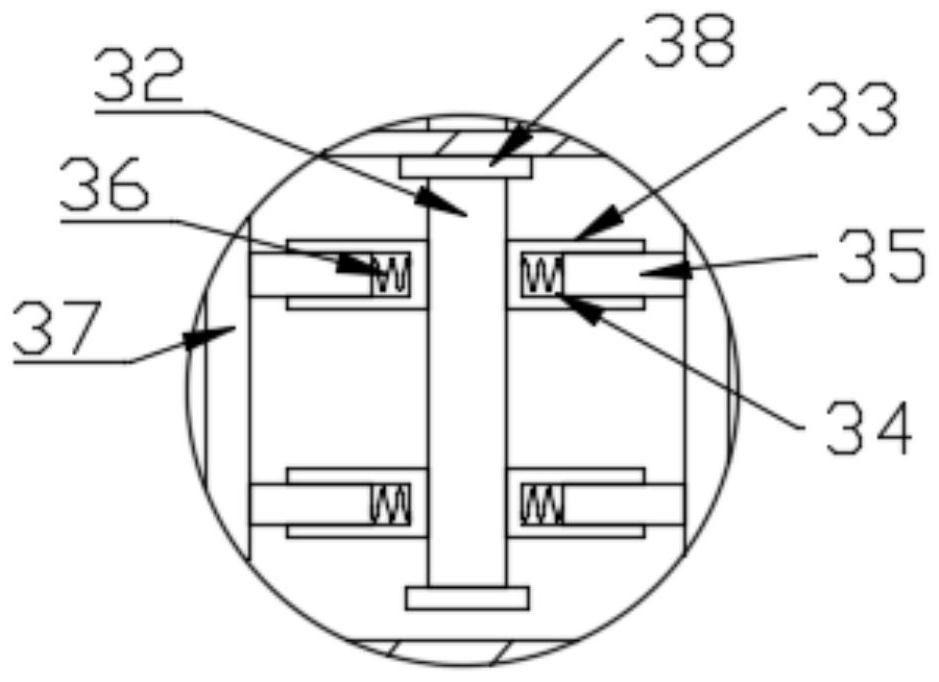

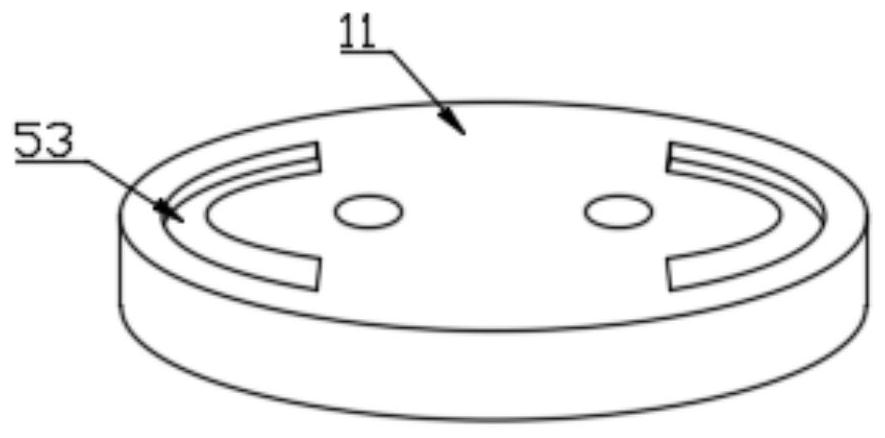

Embodiment 1

[0025] see Figure 1~4 , in an embodiment of the present invention, an ink heat preservation stirring tank includes an outer shell 01 of the stirring tank, a partition box 11 is fixed inside the outer shell 01 of the stirring tank, and an upper inner plate 12 and a lower inner plate are respectively fixed above and below the partition box 11 13. The upper inner plate 12 and the lower inner plate 13 respectively form the upper heat preservation chamber 14 and the lower heat preservation chamber 15 for ink heat preservation in the outer shell 01 of the stirred tank, and the ink can be kept warm through the upper heat preservation chamber 14 and the lower heat preservation chamber 15 , not only can save different types of ink, but also control the temperature of heat preservation according to needs, so that the temperature in the upper heat preservation chamber 14 and the lower heat preservation chamber 15 are different, so that the outer shell of the stirring tank 01 can simultan...

Embodiment 2

[0033] The first temperature sensor 61 and the second temperature sensor 62 are also respectively arranged in the upper heat preservation chamber 14 and the lower heat preservation chamber 15, and the first temperature sensor 61 and the second temperature sensor 62 are connected with the first temperature sensor outside the outer shell 01 of the stirred tank respectively. The temperature display instrument 63 communicates with the second temperature display instrument 64, and then can detect the temperature in the upper insulation chamber 14 and the lower insulation chamber 15 in real time, and then conveniently control the temperature in the upper insulation chamber 14 and the lower insulation chamber 15 according to requirements.

[0034] The working principle of the present invention is: the ink is transferred to the upper heat preservation chamber 14 by the first feed port 21, the ink is transferred to the lower heat preservation chamber 15 by the second feed port 22, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com