A kind of n, s co-doped metal-free cns oxygen reduction catalyst and its preparation method

A catalyst and metal-free technology, applied in metal-air battery oxygen reduction reaction catalyst and fuel cell field, can solve problems such as environmental pollution and complicated preparation process, and achieve the effect of low cost, simple preparation process, and easy scale-up production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

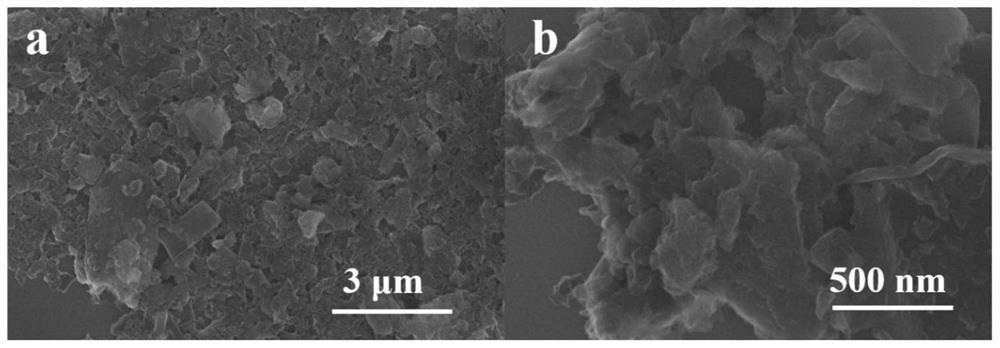

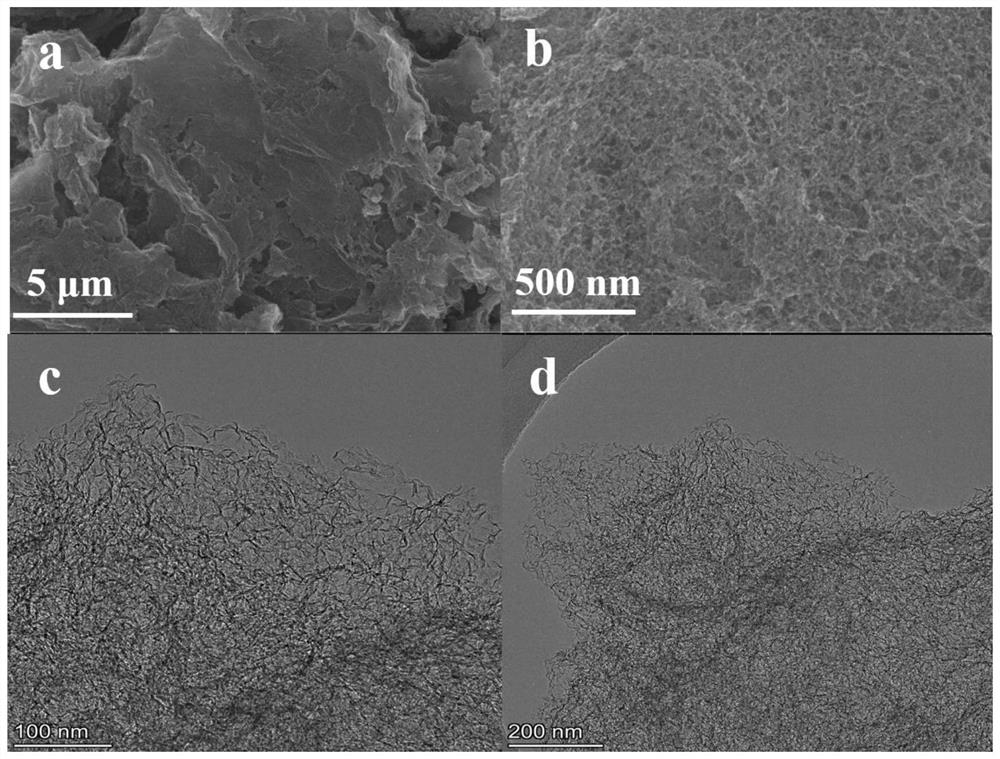

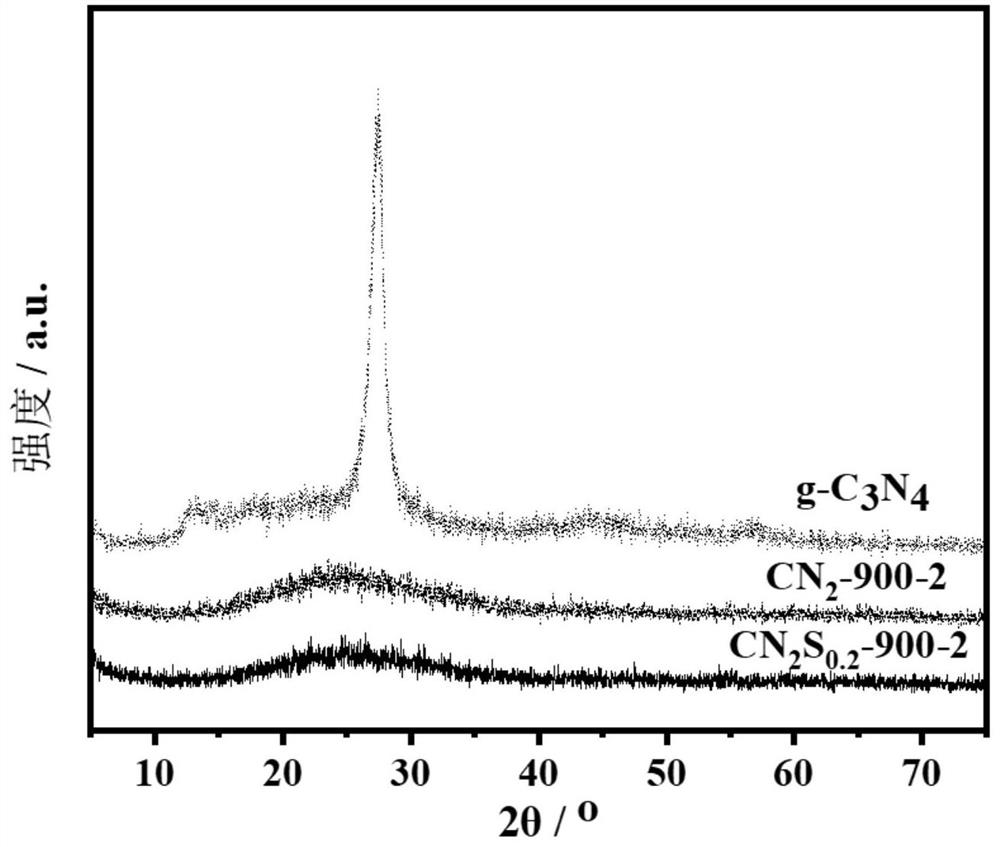

[0034] Example 1: CN 1 S 0.2 -900-2(CN 1 S 0.2 1 in -900-2 means g-C in the raw material 3 N 4 The mass is 1g, 0.2 means the mass ratio of sulfur powder to sodium sulfide is 0.2, 900 means the calcination temperature is 900°C, 2 means the calcination time is 2h)

[0035] 1gg-C 3 N 4 Add to 40mL deionized water, then add 64mg sulfur powder, 280mg sodium sulfide and 200mg glucose, stir for 30min to form a uniform mixed solution A. The mixed solution A was charged into an autoclave, and reacted at 180° C. for 10 h. Then cool to room temperature naturally. Suction filtration, washing, drying in an air oven for 10 hours at 80°C, and then grinding to obtain the CNS catalyst precursor g-C 3 N 4 / CS.

[0036] will g-C 3 N 4 / CS precursor was put into the tube furnace, under N 2 It was calcined under atmosphere for 2 hours, the calcining temperature was 900°C, and the heating rate was 10°C / min. Finally got CN 1 S 0.2 -900-2 Catalyst.

Embodiment 2

[0037] Example 2: CN 2 S 0.2 -900-2(CN 2 S 0.2 2 in -900-2 means g-C in the raw material 3 N 4 The mass is 2g, 0.2 means the mass ratio of sulfur powder to sodium sulfide is 0.2, 900 means the calcination temperature is 900°C, 2 means the calcination time is 2h)

[0038] 2gg-C 3 N 4 Add to 40mL deionized water, then add 64mg sulfur powder, 280mg sodium sulfide and 200mg glucose, stir for 30min to form a uniform mixed solution A. The mixed solution A was charged into an autoclave, and reacted at 180° C. for 10 h. Then cool to room temperature naturally. Suction filtration, washing, drying in an air oven for 10 hours at 80°C, and then grinding to obtain the CNS catalyst precursor g-C 3 N 4 / CS.

[0039] will g-C 3 N 4 / CS precursor was put into the tube furnace, under N 2 It was calcined under atmosphere for 2 hours, the calcining temperature was 900°C, and the heating rate was 10°C / min. Finally got CN 2 S 0.2 -900-2 Catalyst.

Embodiment 3

[0040] Example 3: CN 3 S 0.2 -900-2(CN 3 S 0.2 3 in -900-2 means g-C in the raw material 3 N 4 The mass is 3g, 0.2 means the mass ratio of sulfur powder to sodium sulfide is 0.2, 900 means the calcination temperature is 900°C, 2 means the calcination time is 2h)

[0041] 3gg-C 3 N 4 Add to 40mL deionized water, then add 64mg sulfur powder, 280mg sodium sulfide and 200mg glucose, stir for 30min to form a uniform mixed solution A. The mixed solution A was charged into an autoclave, and reacted at 180° C. for 10 h. Then cool to room temperature naturally. Suction filtration, washing, drying in an air oven for 10 hours at 80°C, and then grinding to obtain the CNS catalyst precursor g-C 3 N 4 / CS.

[0042] will g-C 3 N 4 / CS precursor was put into the tube furnace, under N 2 It was calcined under atmosphere for 2 hours, the calcining temperature was 900°C, and the heating rate was 10°C / min. Finally got CN 3 S 0.2 -900-2 Catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com