Bottom hole three-jaw centering mobile platform applied to special environment

A mobile platform and bottom surface technology, applied in the direction of lifting devices, lifting frames, wheels, etc., can solve the problems of operation restrictions, large damage, etc., and achieve the effects of good mobility, accurate grinding and cleaning, and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

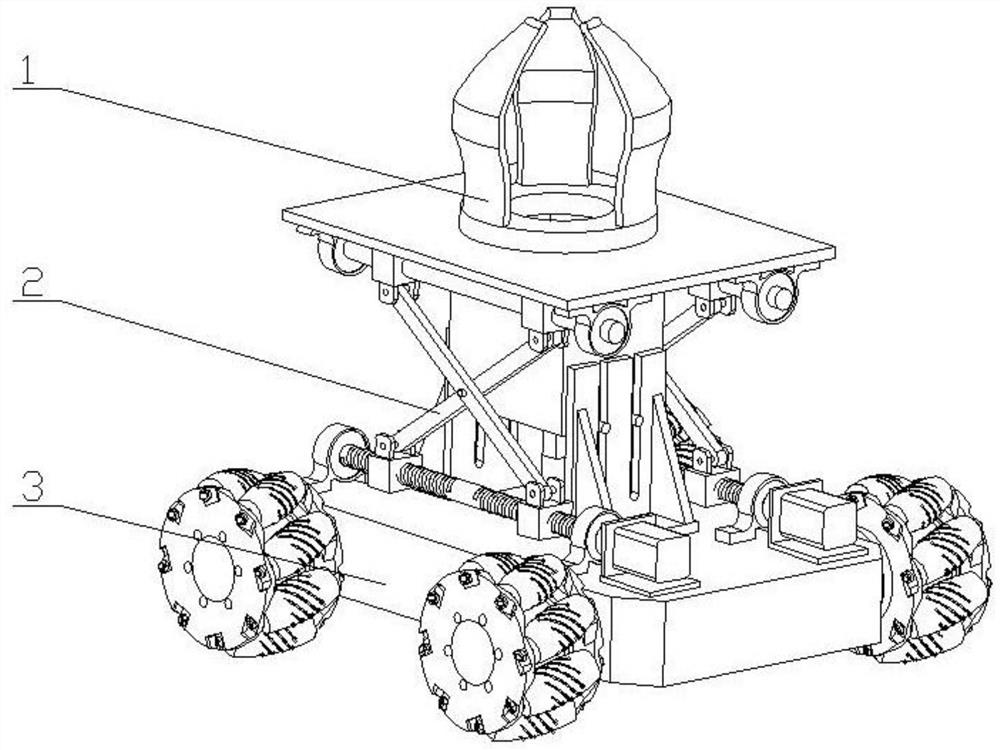

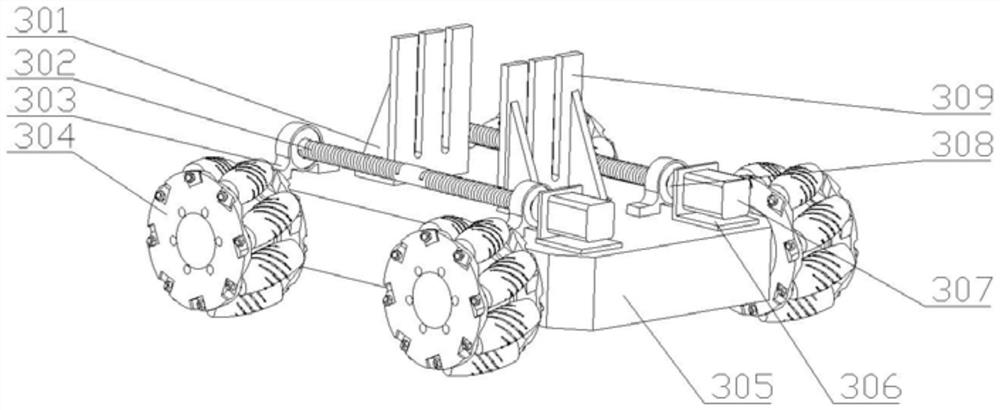

[0015] see figure 1 , 2 , 3, including a centering structure 1, a lifting bracket assembly 2 and a vehicle body 3, wherein the lifting bracket assembly 2 is fixedly connected above the vehicle body 3, and the centering structure 1 is fixedly connected above the lifting bracket assembly 2, and the vehicle body The structure of 3 is: the car body 305 is connected with four mecanum wheels 304 respectively with servo motors, the four servo motors are directly fixed on the car body 305, the bottom surfaces of the two motor brackets 306 are respectively fixed on the car body 305, and the motors The vertical surface of the bracket 306 is used to fix the motor 307, the output shaft of the motor 307 is connected with the lead screw 302 through a coupling 308, so as to realize power transmission, and each lead screw has a bearing 303 at both ends for fixing and limiting , two mirrored guide plates 309 are installed on the car body, the bottom surface of the guide plate 309 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com