Gear chamfering tool assembly and vertical gear chamfering machine

A chamfering machine and chamfering technology, applied in the direction of belt/chain/gear, gear teeth, mechanical equipment, etc., can solve the problems of long switching time, cumbersome tool switching process, etc., to improve processing efficiency, shorten processing auxiliary time, Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

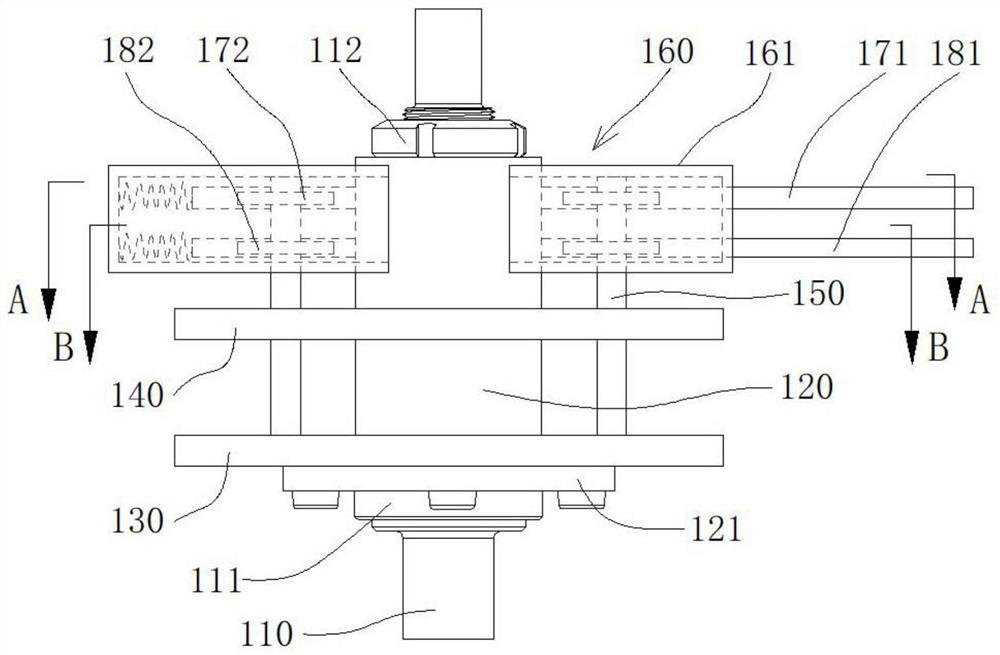

[0041] This embodiment provides a gear chamfering knife assembly, such as figure 1 As shown, in a preferred embodiment, it includes a mandrel 110, the mandrel 110 is sleeved with a knife shaft 120 coaxial with it and axially limited, and the knife shaft 120 is sleeved with a coaxial connection with it The upper cutter head 130 and the lower cutter head 140 are arranged in parallel, and the lower cutter head 140 is located below the upper cutter head 130 . Wherein, the lower cutter head 140 is fixedly connected with the cutter shaft 120. For example, the lower end of the cutter shaft 120 has a flange 121, and the lower cutter head 140 and the flange 121 are fastened and connected by bolts; Fixed and axially movable along the cutter shaft 120 , the gear chamfering cutter assembly also includes a driving mechanism that drives the upper cutter head 130 to move axially on the cutter shaft 120 and has a self-locking function.

[0042] Wherein, the drive mechanism includes two screw...

Embodiment 2

[0058] This embodiment provides a kind of vertical gear chamfering machine, such as Figure 4As shown, in a preferred embodiment, the vertical gear chamfering machine includes a bed 200, a vertical workpiece spindle 300 installed on the front of the upper end of the bed 200, and a The column 210 , the chamfering module 400 installed on the left front of the column 210 , and the deburring module 500 installed on the right front of the column 210 . The chamfering module 400 includes a chamfering knife assembly 100 and a chamfering knife position adjustment device 410, the chamfering knife assembly 100 is the gear chamfering knife assembly in the first embodiment, the mandrel 110 of the chamfering knife assembly 100 is connected with The workpiece spindles 300 are arranged in parallel, that is, they are all arranged vertically.

[0059] During chamfering, the mandrel 110 is fixed relative to the workpiece spindle 300 , and the cutter shaft 120 is rotatably connected to the mandr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com