Noise reduction structure and gas water heater applying same

A technology for water heaters and noise reduction, which is applied to fluid heaters, instruments, and sound-generating devices. It can solve problems such as noise, reduce noise, improve user experience, and ensure noise reduction effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

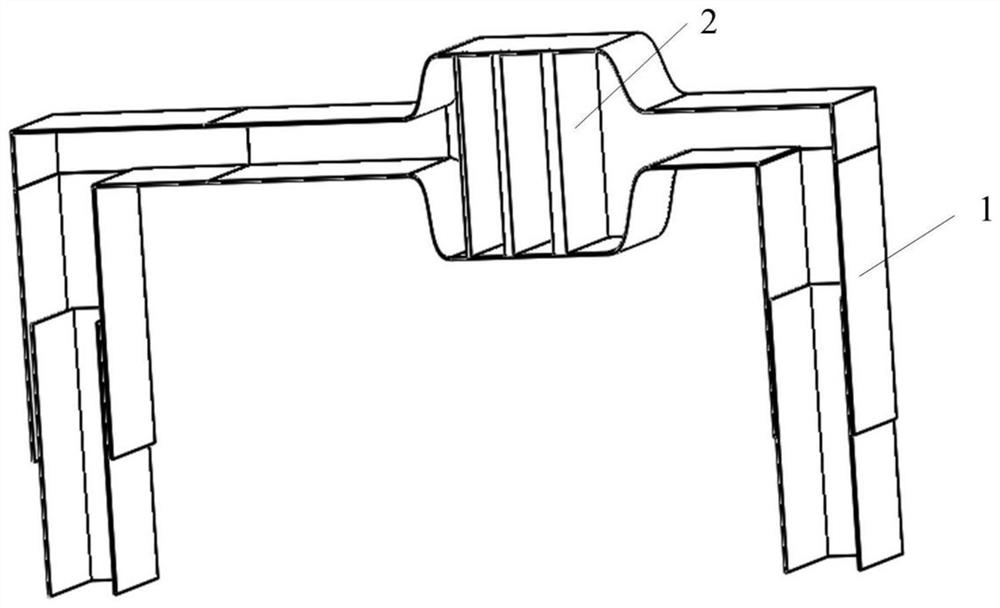

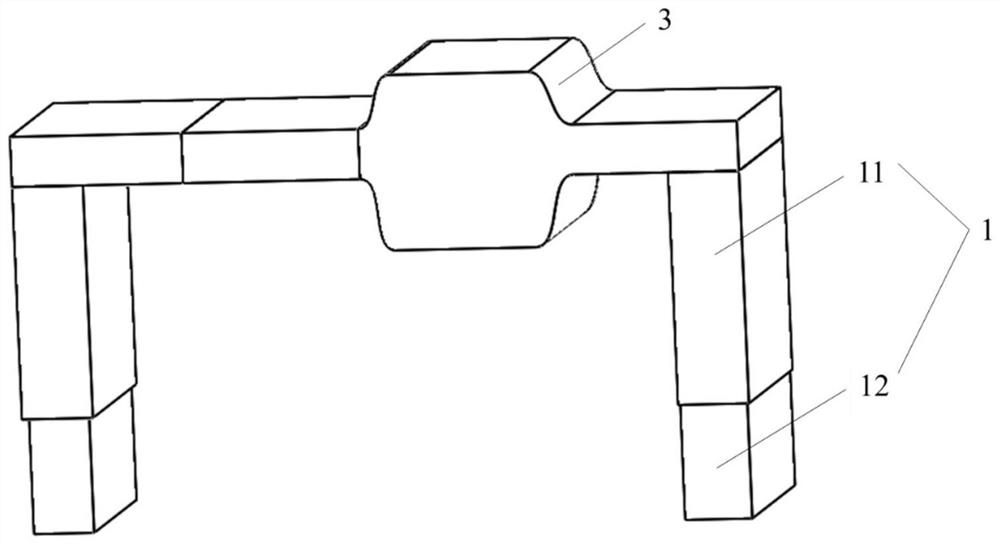

[0030] This embodiment provides a noise reduction structure, such as figure 1 and figure 2 As shown, it includes a sound channel 1 and a sound-absorbing layer 2; the sound channel 1 has openings at both ends, and both ends can be extended outwards, which is used to adjust the length of the sound channel 1 according to the wavelength of the noise. The sound-absorbing layer 2 is arranged in the sound channel 1 and is at least one layer.

[0031] In this way, both ends of the sound channel 1 are open, and the noise enters from both ends of the sound channel 1, resulting in a standing wave effect, resonance and noise elimination, that is, the sound channel 1 forms a resonant standing wave structure, thereby achieving noise reduction;

[0032] At the same time, the two ends of the sound channel 1 can be extended outward, that is, the length of the sound channel 1 can be adjusted, and can be adjusted according to the wavelength of the noise. For example, the length of the sound ch...

Embodiment 2

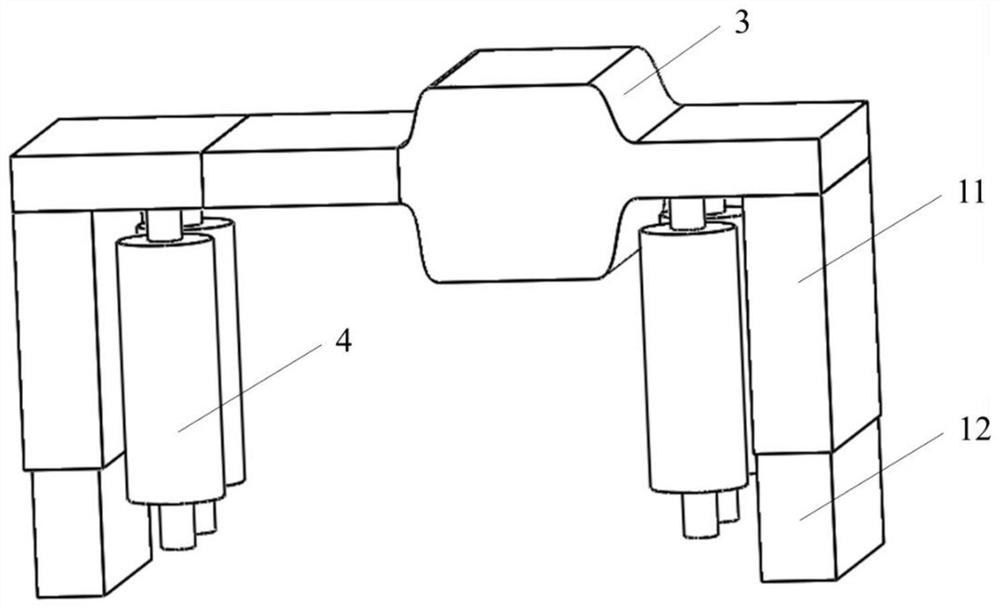

[0059] This embodiment provides a gas water heater, such as Figure 5 and Figure 6 As shown, the gas water heater includes the noise reduction structure of Embodiment 1, the water heater body 5, the fan assembly 6 and the control assembly 7, the fan assembly 6 is arranged in the water heater body 5, the sound channel 1 and the drive The component 4 is arranged on the water heater body 5, the control component 7 is electrically connected with the fan component 6 and the drive component 4, at least for obtaining the maximum noise wavelength according to the rotation speed of the fan component 6, and through The driving assembly 4 adjusts the length of the sound channel 1 to be 1 / 4 of the maximum noise wavelength.

[0060] Specifically, the fan assembly 6 is arranged in the water heater main body 5, the control assembly 7 is arranged on the water heater main body 5, the extension body 12 in the sound channel 1 is connected with the water heater main body 5, the driving assembly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com