Transformer substation operation inspection robot and electrified area isolation method thereof

A live area and robot technology, which is used in instruments, electrostatic field measurement, radio wave measurement systems, etc., can solve the problems that operators are easy to enter the live area by mistake, the transportation equipment does not have the hardware structure and method of isolating the live area, and the hidden dangers of safety. , to achieve the effect of improving the overall intelligence level, shortening the maintenance time of power outages, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

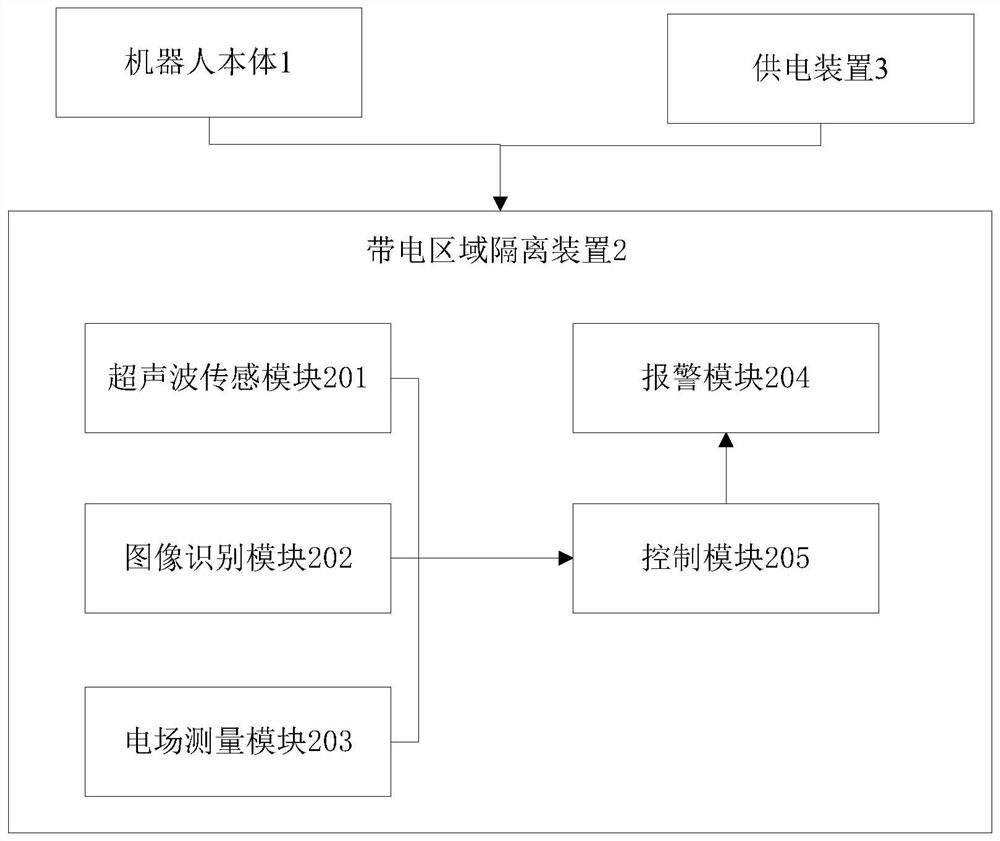

[0041] The embodiment of the present invention provides a substation inspection robot, such as figure 1 As shown, it includes the robot body 1, the live area isolation device 2 and the power supply device 3. The live area isolation device and the power supply device are respectively installed on the robot body. The live area isolation device is used to help the robot body to actively isolate the charged area during the movement of the robot body. In the area, the robot body is used to transport the test instruments required for substation testing, and the power supply device is used to supply power to the robot body, live area isolation device and test instruments.

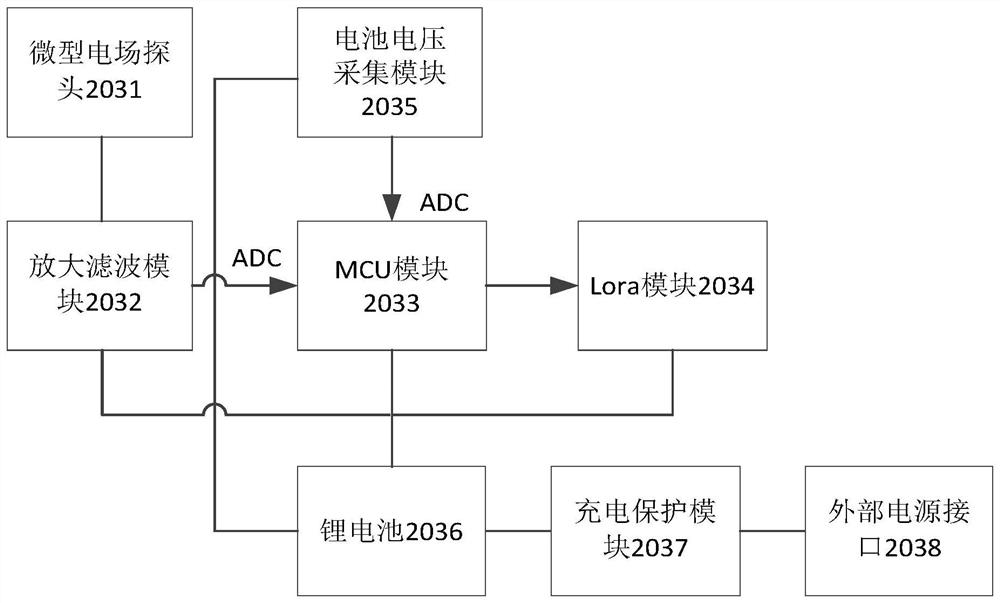

[0042]The charged area isol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com