Paper conveying speed-change device for money-printing gravure printing machine

A technology of speed change device and gravure printing machine, which is applied in the direction of transmission device, transportation and packaging, vehicle gearbox, etc. Efficiency, cost saving, less difficult to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

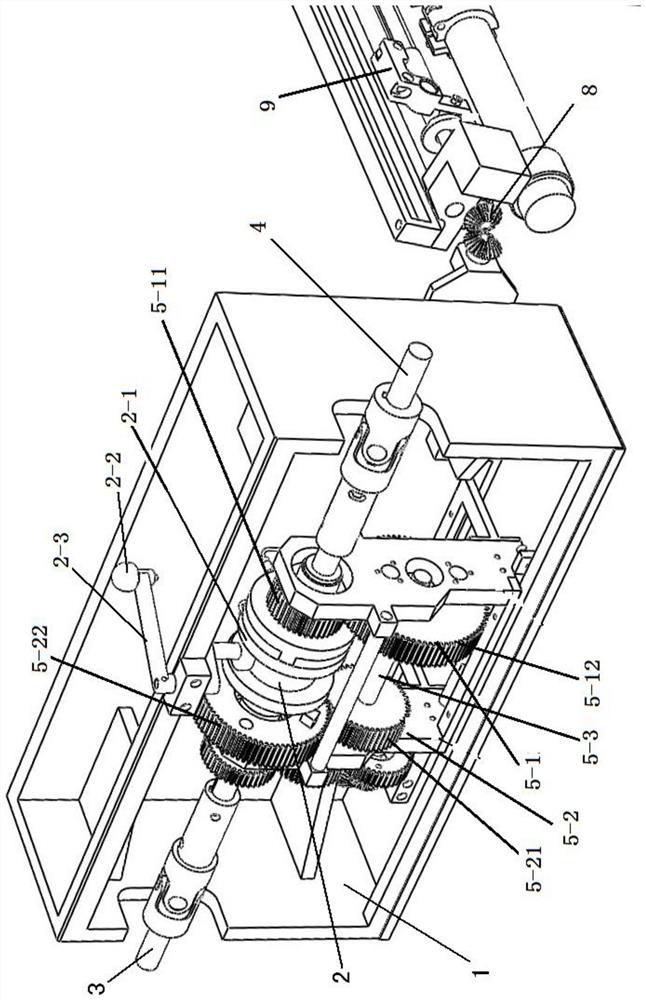

[0031] see figure 1 , the banknote printing gravure printing machine paper feeding speed change device in the present embodiment, comprises frame 1, is provided with power input shaft 4 and power output shaft 3 concentrically on frame 1, the end of power input shaft 4 and power output shaft 3 The shift gears 5 are respectively connected, including the input shift gear 5-1 installed at the end of the power input shaft 4, the output shift gear 5-2 installed at the end of the power output shaft 3, and the two groups of shift gears 5 face each other. Mounted close to each other at the ends of the two shafts.

[0032] A reciprocating sliding dial 2 is installed between the shift gear 5, and the sliding dial 2 controls the on-off of the power output shaft 3 and the power input shaft 4, and at the same time realizes the connection between the power output shaft 3 and the power input shaft 4 through the shift gear. synchronous or asynchronous rotation.

[0033] Specifically, the pap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com