Ultralow-water-content sludge dewatering and drying system and drying treatment method thereof

A moisture content and drying technology, which is applied in water/sludge/sewage treatment, sludge treatment, dehydration/drying/thickened sludge treatment, etc., can solve the problems of long time-consuming cycle, high moisture content and insufficient drying To achieve the effect of reducing moisture content, high drying efficiency and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

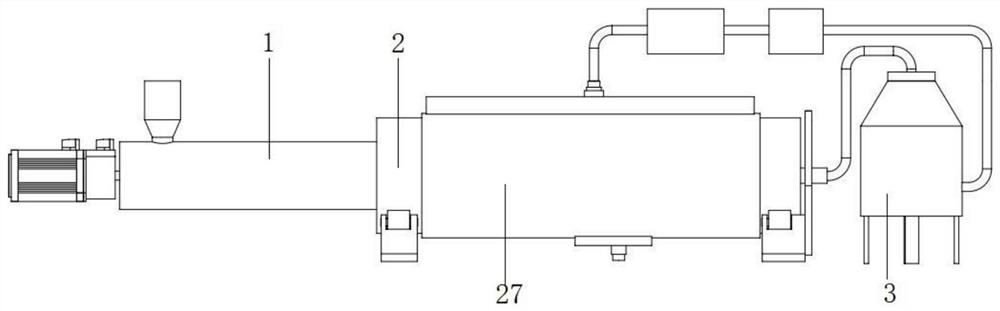

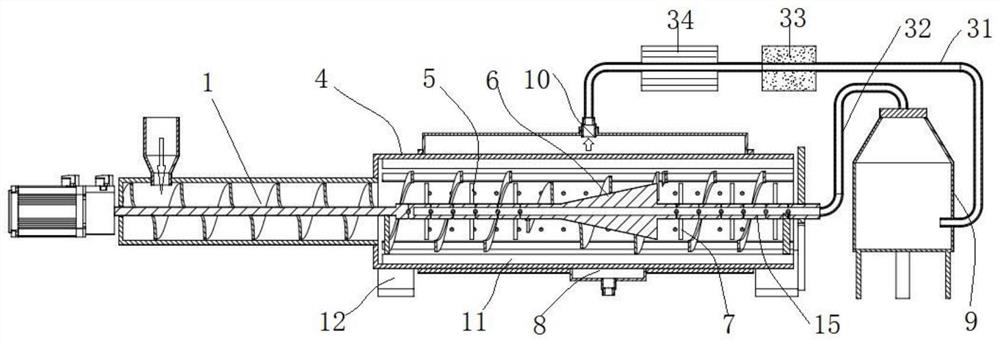

[0025] as attached figure 1 to attach Figure 4 As shown, an ultra-low moisture content dehydration and drying system for sludge includes a dehydration device 1, a drying device 2, and a waste gas treatment device 3. The dehydration device 1 can be a filter press or a centrifugal detachment mechanism, etc., and the The drying device 2 includes a drying container 4 and a primary crushing mechanism 5, a mud cake forming mechanism 6, and a secondary crushing mechanism 7 arranged at successive intervals along the length direction of the drying container 4. The primary crushing mechanism 5 corresponds to the dehydration device 1, the mud cake forming mechanism 6 press-filters the sludge after passing through the primary crushing mechanism 5 to form a mud cake, and the drying container 4 is provided with a filtrate port 8 corresponding to the mud cake forming mechanism 6 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com