An elevator counterweight frame

A counterweight frame and elevator technology, which is applied to lifting equipment, brake components, elevators, etc. in mines, can solve problems such as inability to move, insufficient braking force, and elevator displacement, and achieve strong applicability and improved safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below with reference to the accompanying drawings.

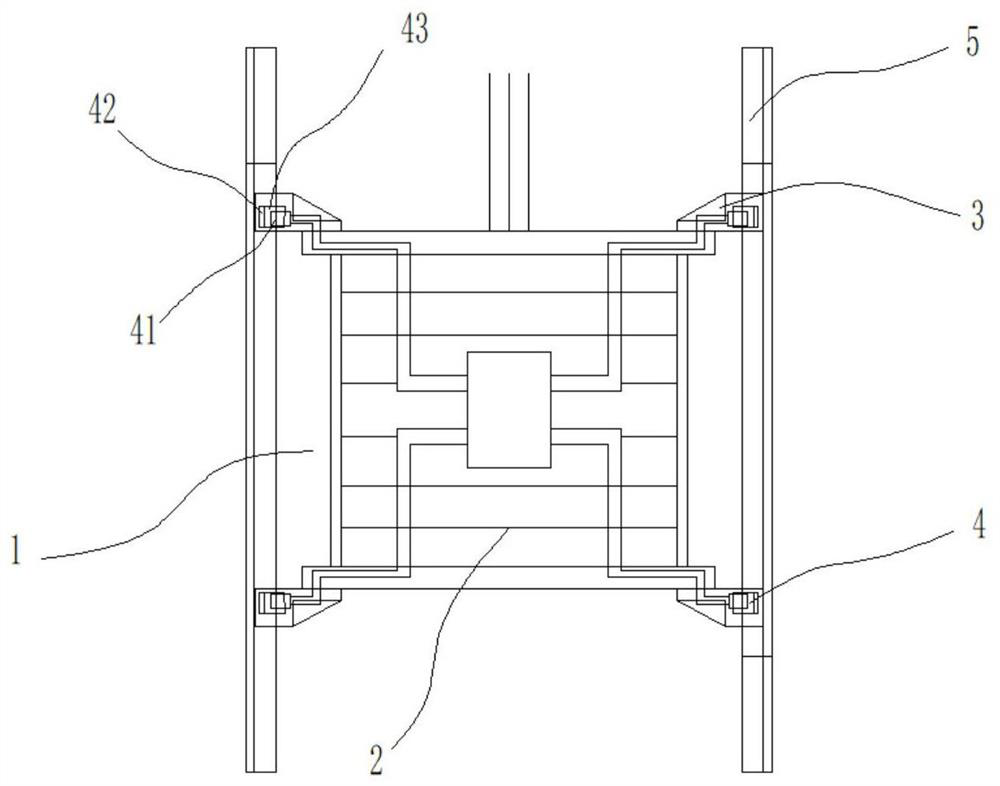

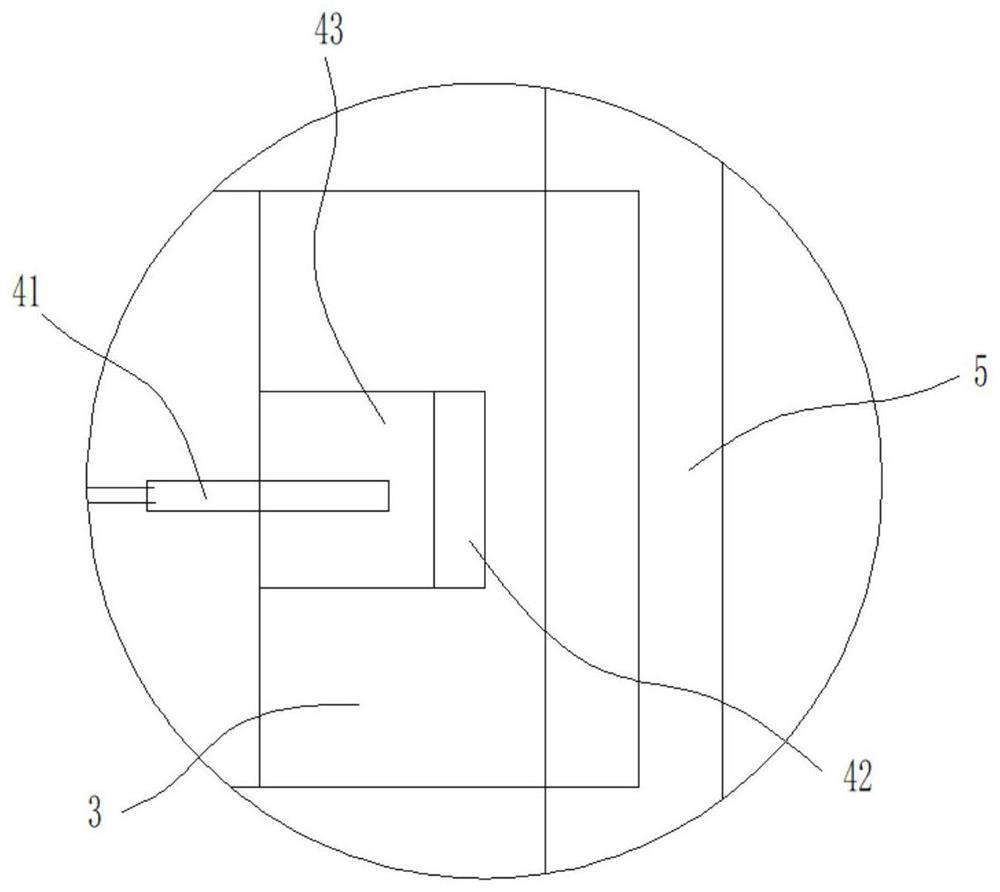

[0022] Such as figure 1 and 2 As shown, an elevator is retaining, including the casing 1 and a counterweight block 2, the frame 1 provided having a guide shoe 3, a brake member 4, and a guide rail 5, including a semiconductor refrigeration piece 41, suction The heat sheet 42 and the phase change layer 43 connected to both, the brake member 4 is disposed on one side of the guide rail 5. The guide shoe 3 slides on the guide rail 5 to realize the weight of the heavy-frame, and the heat formed between the two between the two is heat dissipated by the brake member 4, wherein the heat absorbing sheet 42 is described. There is a space between the guide rails 5, the heat absorbing sheet 42 absorbs heat to the phase change layer 43, the phase change layer 43 phase transition layer forms a gas chamber, the volume is gradually large, the semiconductor refrigeration piece 41 S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com