Spherical workpiece fixing method for riveting press

A fixing method and technology of a riveting press, which are applied in the cleaning methods, chemical instruments and methods, cleaning methods and utensils using gas flow, etc., can solve the problems of lack of fixing devices, etc., and achieve the effect of improving the fixing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

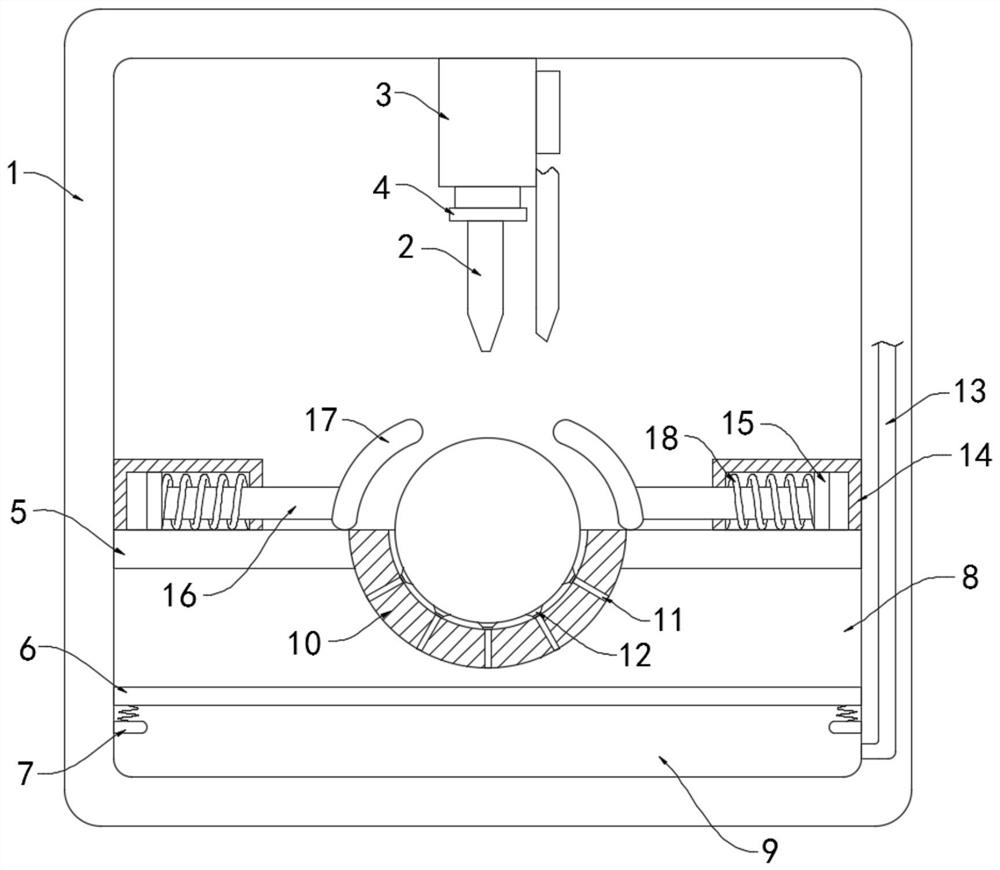

[0028] Such as Figure 1-2 As shown, a method for fixing a spherical workpiece of a riveting press, the specific fixing method is as follows:

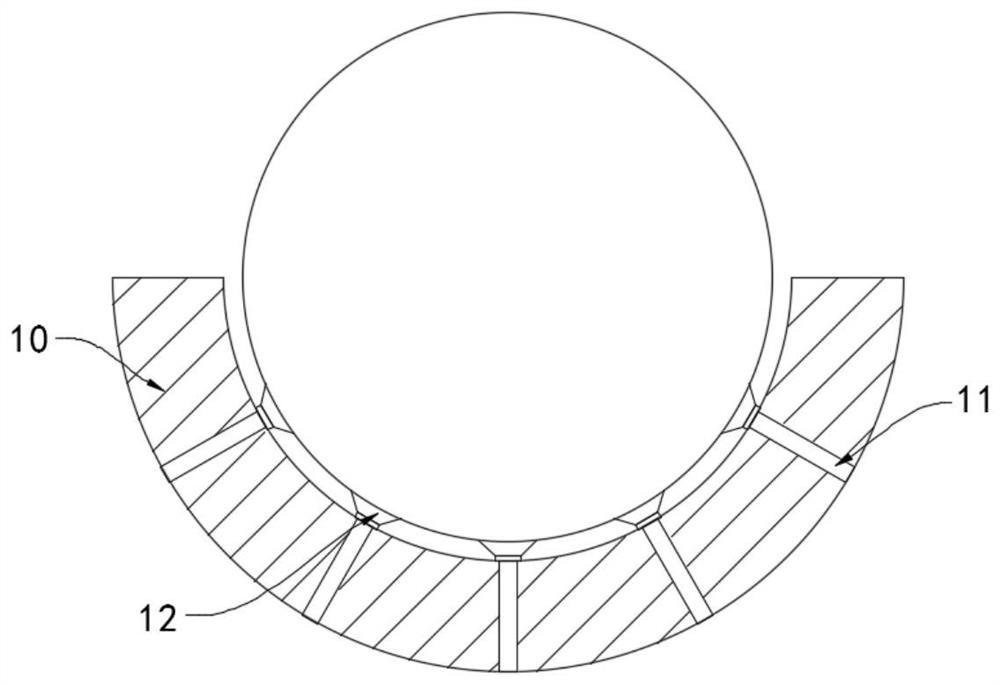

[0029] S1, placing, placing the spherical workpiece to be riveted in the fixing groove 10 on the fixing table 5;

[0030] S2. The bottom surface is fixed. When the riveting head 2 drives the magnetic ring 4 to move down, the repulsion between the magnetic block in the sliding plate 6 and the magnetic ring 4 will make the sliding plate 6 slide downward, so that the air pressure in the upper chamber 8 Reduced, the suction cup 12 will be tightly adsorbed on the lower surface of the spherical workpiece under the action of negative pressure, and the spherical workpiece will be fixed at the bottom;

[0031] S3, the side is fixed, when the riveting joint 2 drives the magnetic ring 4 to move down, the magnetic field strength in the induction coil 18 changes to make it generate current, so that the induction coil 18 shrinks, and the moving arc...

Embodiment 2

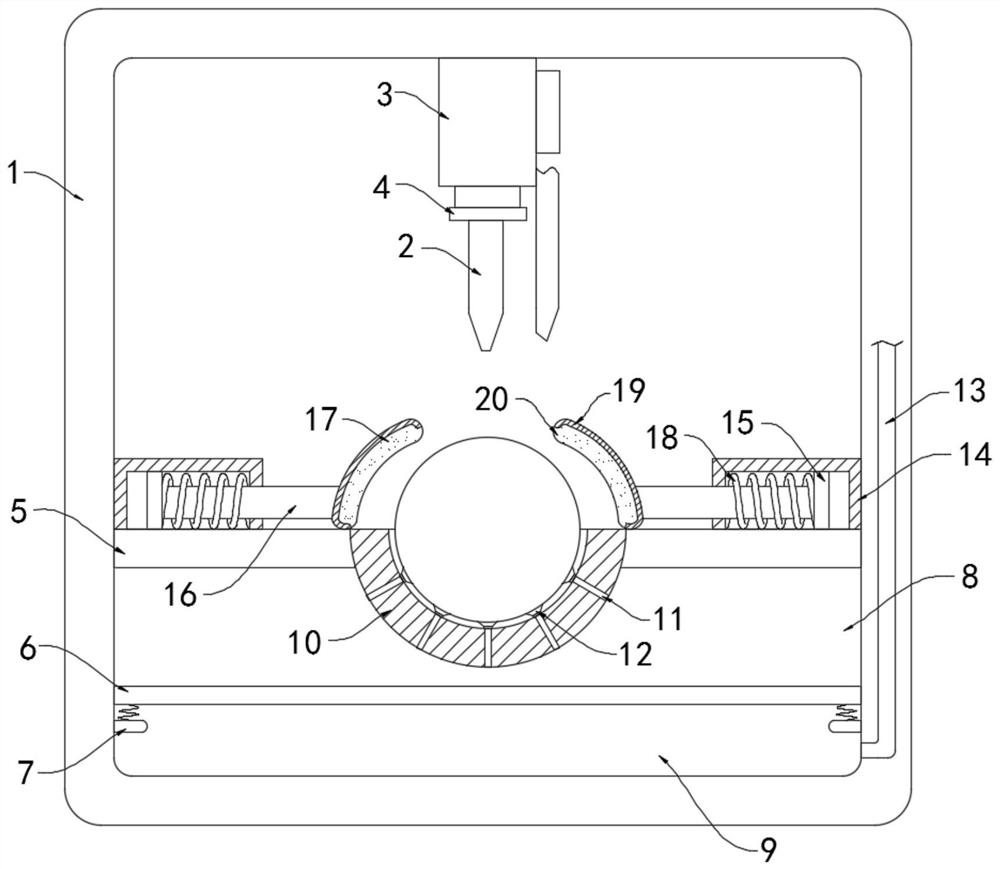

[0047] Such as Figure 3-4 As shown, the difference between this embodiment and Embodiment 1 is that the arc clamp 17 includes an outer hard shell 19 and an elastic bag 20 filled with electrorheological fluid inside the inner layer, and the elastic bag 20 is fixedly embedded There are conductive threads.

[0048] In this embodiment, when the arc clamp 17 moves toward the workpiece, the elastic capsule 20 in the soft state inside the arc clamp 17 will fit the surface of the spherical workpiece, and when the riveting head 2 is connected to the workpiece through the riveting nail, The electrorheological fluid in the arc clamp 17 will solidify when it is energized instantly, and the cured electrorheological fluid fits the surface of the workpiece more effectively, which can further effectively improve the fixing effect on the workpiece.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com