Simulation test system for upward drilling low-temperature fluid fracturing and method thereof

A simulation test system, low temperature fluid technology, applied in the field of coal seam fracturing test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below.

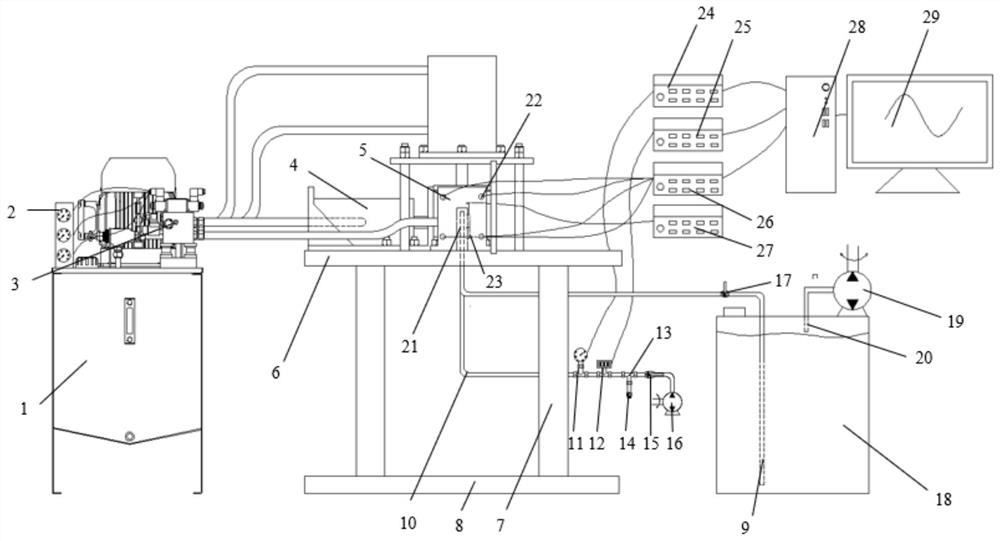

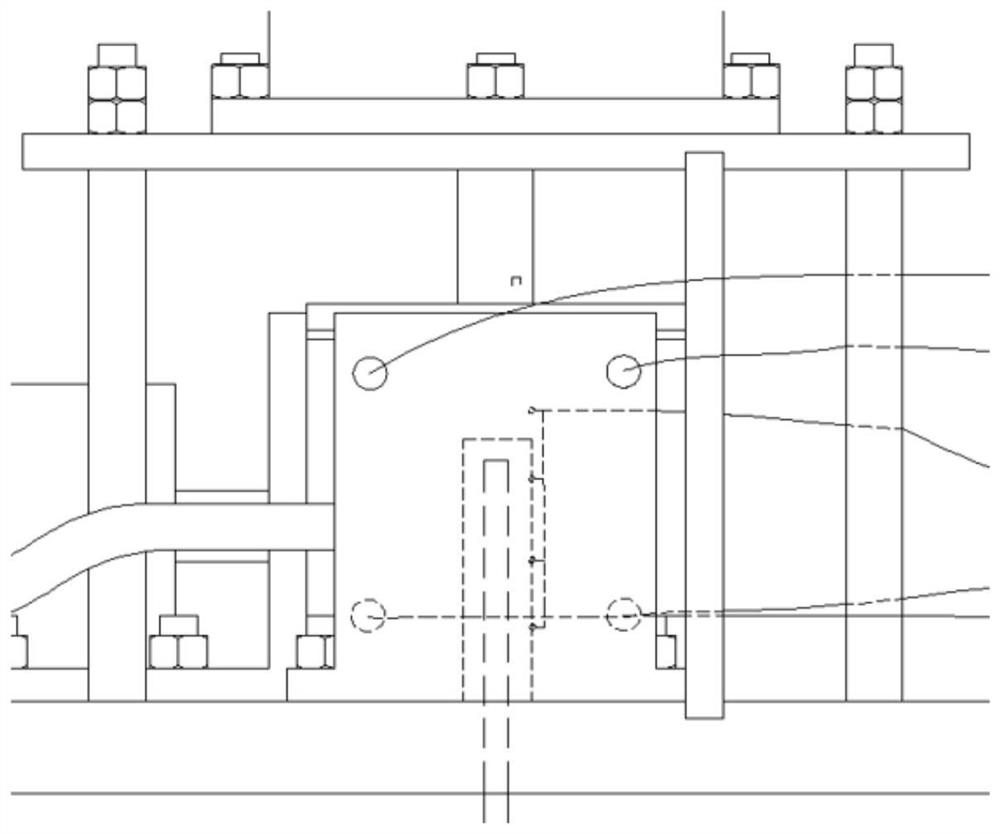

[0027] Such as figure 1 and figure 2 As shown, a simulation test system for uphole cryogenic fluid fracturing, including a true triaxial loading device, a test bench, a data monitoring device and a cryogenic fluid injection device,

[0028] The test bench includes a support plate and a base, the support plate is directly above the base, and the support plate and the base are fixedly connected by a plurality of columns;

[0029] The true triaxial loading device includes a hydraulic control box, a hydraulic controller, a pressure gauge, a hydraulic loading cylinder, a loading plate and a baffle, and there are three hydraulic controllers, a pressure gauge, a loading plate, a hydraulic loading cylinder and a baffle, Three loading plates and three baffles are arranged on the support plate, and the three loading plates and three baffles enclose a cubic loading chamber, and the three groups of opposite faces of the load...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com