A prefabricated building wall positioning machine

A building wall, prefabricated technology, applied in the direction of buildings, building components, building structures, etc., can solve the problems of low efficiency, long time required for installation and disassembly, reduce the number of uses, improve the efficiency of installation and disassembly, The effect of facilitating initial positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the techniques, creative characteristics of the present invention, it is easy to understand that the present invention is further illustrated in connection with the specific embodiments.

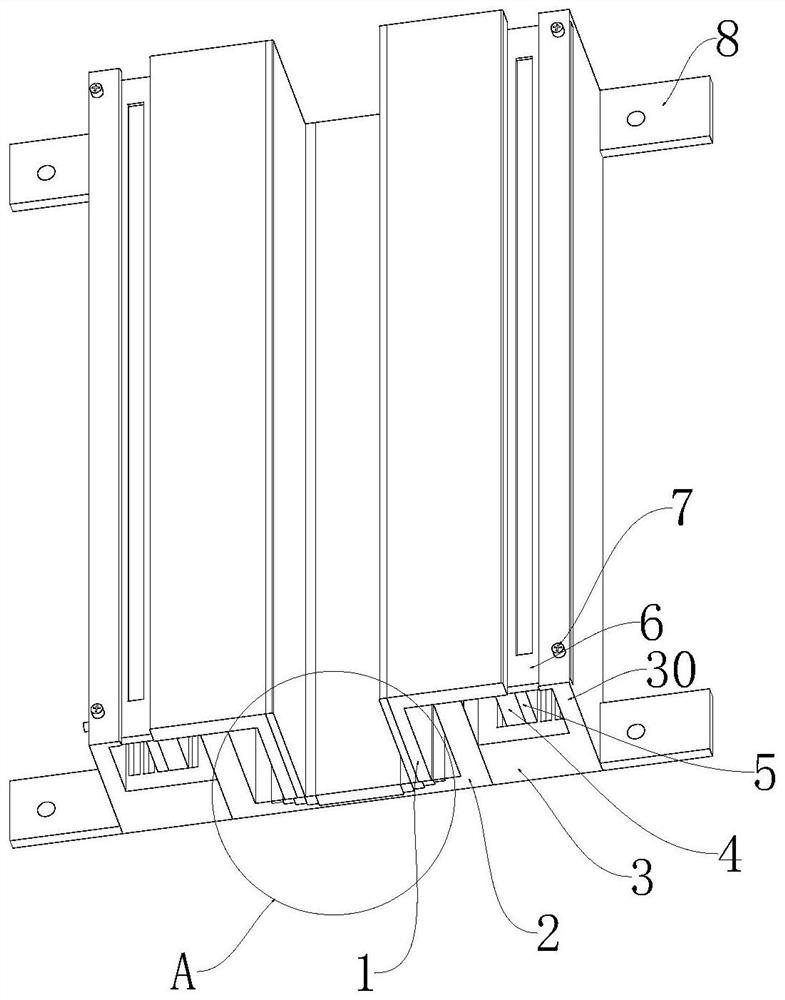

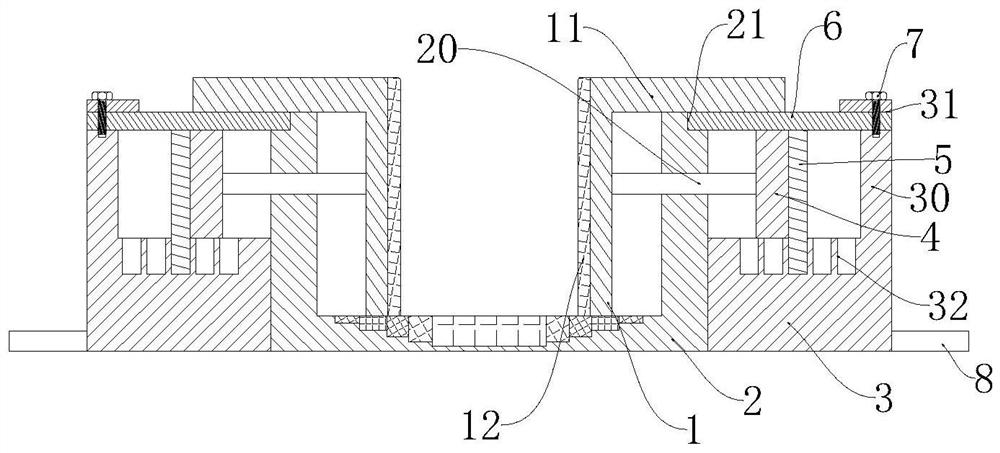

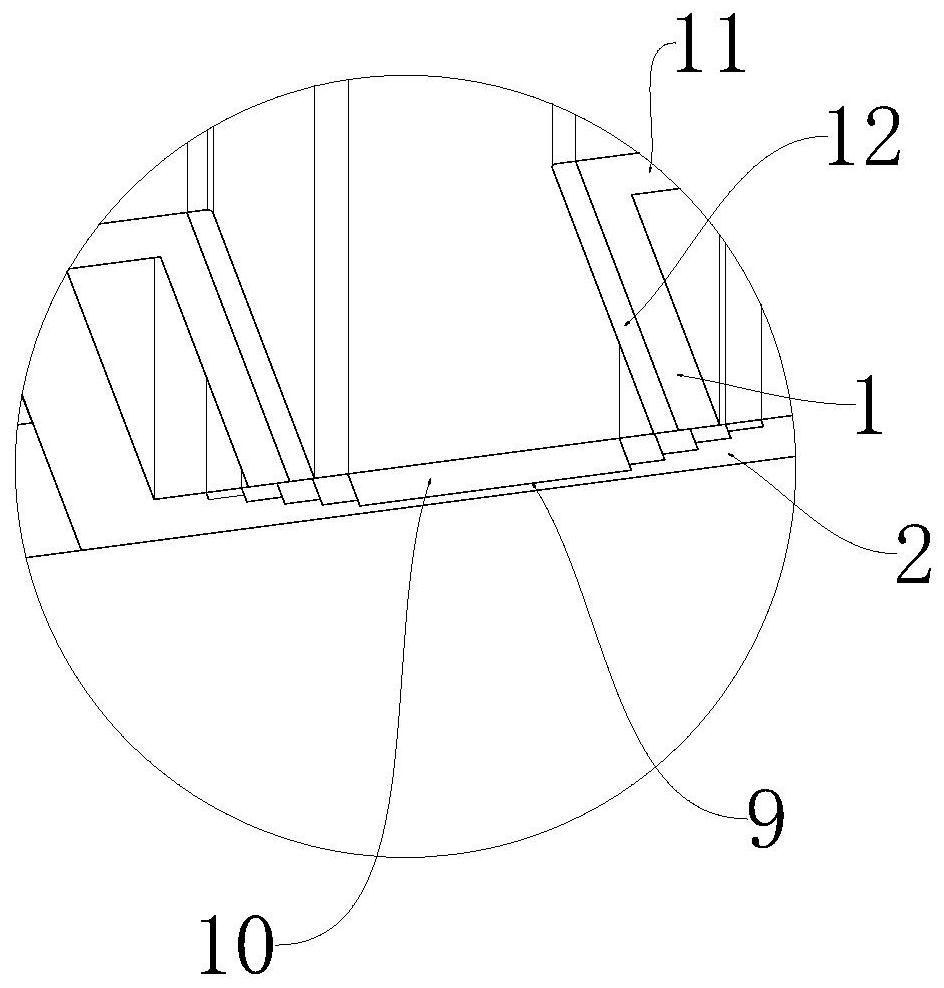

[0020] See Figure 1 - Figure 3 The present invention provides a technical solution: an assembled building wall positioning machine, including a U-shaped frame 2 of the upper opening opening, and the U-shaped frame 2 slides on the bottom end of the U-shaped frame 2 and two compact pinches 1 and two compression The splint 1 is configured, and the two compressing clamp 1 is fixed, and the connecting shaft 20 is fixed, and the connecting shafts 20 of the left and right sides are respectively through the U-shaped frame 2 left end and the right end, and the U-shaped frame 2 is fixed to both ends. 3, the upper end of the two side panels 3 is equal to at least two lock grooves 32, and the upper ends of the two side plates 3 are provided with an outer plate 4, and the connecting s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com