Vortex generator and method for delaying stall attack angle of wing with high aspect ratio

A technology of vortex generators and large aspect ratios, which is applied in the aviation field, can solve problems such as no vortex generators, and achieve the effects of increasing the maximum available lift coefficient, delaying air separation, and making up for technical gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

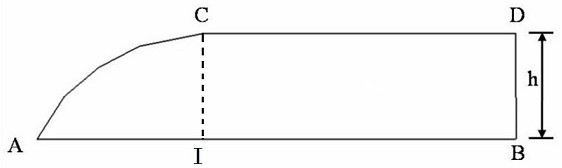

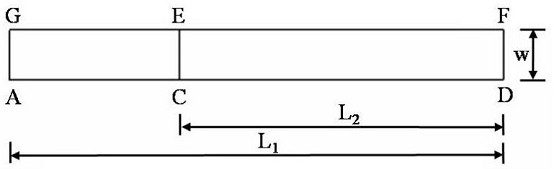

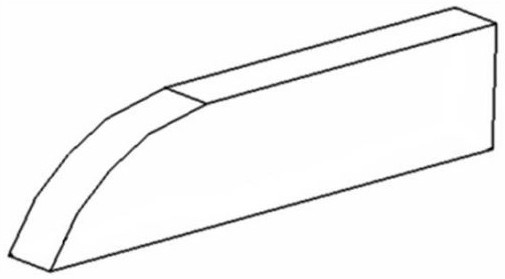

[0039] This embodiment proposes a vortex generator for delaying the stall angle of attack of a large aspect ratio wing, which is installed on a large aspect ratio swept wing, such as figure 1 , figure 2 , image 3 As shown, the vortex generator is a panel with a thickness of w, including an integrally connected rectangular panel part CDBI, and an arc fan-shaped right-angle panel part ACI;

[0040] The rectangular panel part CDBI is a rectangular panel, the bottom side length IB of the rectangular panel is L2, and the side side length BD is h;

[0041] The arc fan-shaped right-angled panel part ACI is connected with the rectangular panel part CDBI with a length IC of a right-angled side length IC, and the length of the other right-angled side AI not connected with the rectangular panel part CDBI is L3; the circle formed by two right-angled sides The length of the arc side AC is s; the length of the side length AB is L2+L3;

[0042] The arc side AC is divided into two sectio...

Embodiment 2

[0046] The present invention also provides a manufacturing method of a vortex generator, which is used to manufacture the above-mentioned vortex generator, such as figure 1 , figure 2 , image 3 , Figure 4 As shown, first calculate and generate the planar shape ABDC of the vortex generator; then generate a vortex generator with a thickness w according to the planar shape ABDC;

[0047] When calculating the plane shape ABDC, at first it is necessary to calculate the length h of the side length BD of the rectangular panel part CDBI, which is also the length h of the right-angled side length IC connected by the arc fan-shaped right-angled panel part ACI and the rectangular panel part CDBI; The length of h is determined according to the thickness of the boundary layer at the wing station where the vortex generator is placed, and is slightly greater than or equal to the thickness of the local boundary layer.

[0048]Further, after the value of h is calculated, the length of L2...

Embodiment 3

[0055] The present invention also provides a method for installing and using the vortex generator, which is suitable for the installation of the above-mentioned vortex generator. 10°~30°.

[0056] In order to better realize the present invention, further, when multiple vortex generators are installed at the same time, the distance between two vortex generators is set to be 2.5%-10% of the half length.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com