Engine assembling follow fixture

A traveling fixture and generator technology, applied in manufacturing tools, workpiece clamping devices, etc., can solve the problems of reducing assembly efficiency, bumping the motor, unable to meet the requirements of automatic assembly production lines, etc., to achieve simple structure, improve adaptability, Install stable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples are only used to explain the present invention, but not to limit the scope of the present invention.

[0022] The generator assembly accompanying fixture of the present invention is suitable for generators with pulleys at the ends and ear holes on the end covers adjacent to the pulleys.

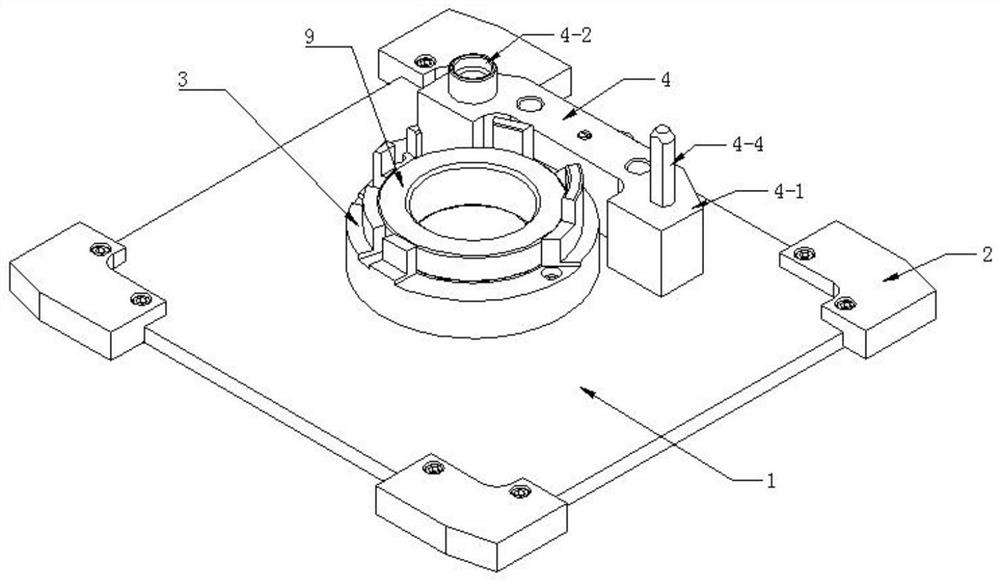

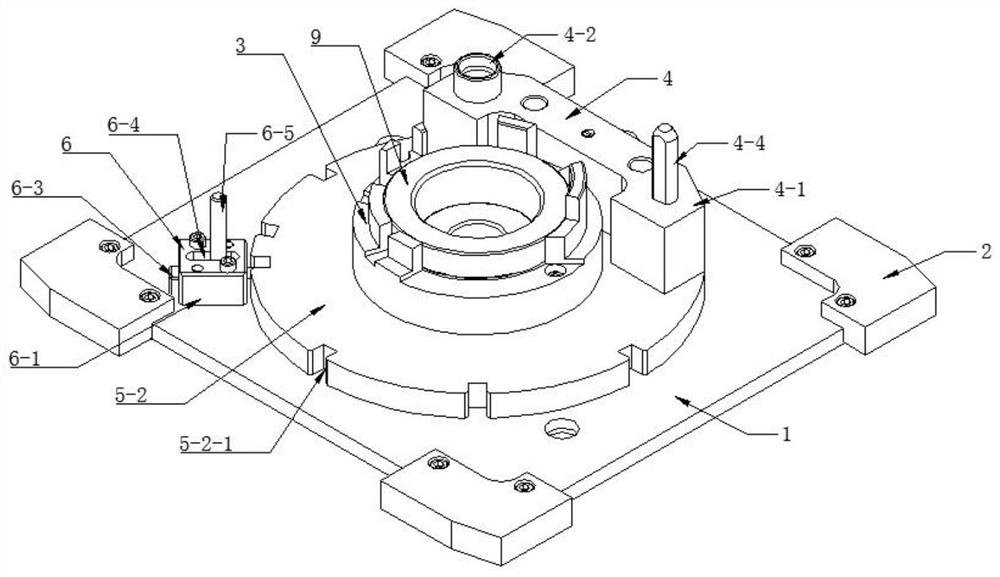

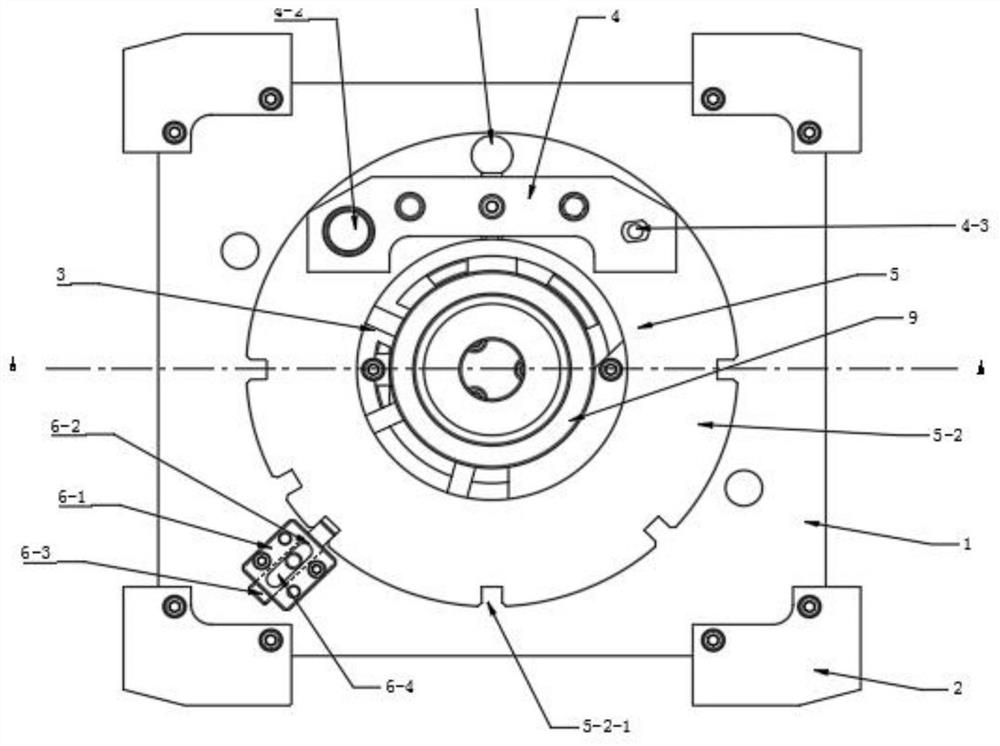

[0023] like figure 1 It is a perspective view of the first embodiment of the present invention. As can be seen from the figure, the generator assembly traveling fixture includes a support plate 1 and blocks 2 installed on the four corners of the support plate 1. The center of the support plate 1 is fixedly installed with a positioning ring 3, and the positioning ring 3 is also fixedly arranged with a Match the spacer 9 with the generator pulley. It can be seen from the figure that the end surface of the outer ring of the positioning ring 3 is flat, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com