Alternating current welding machine power supply control system

A technology for power control and electric welding machine, applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of inconvenient movement, large size and weight of electric welding machine, waste of electricity and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

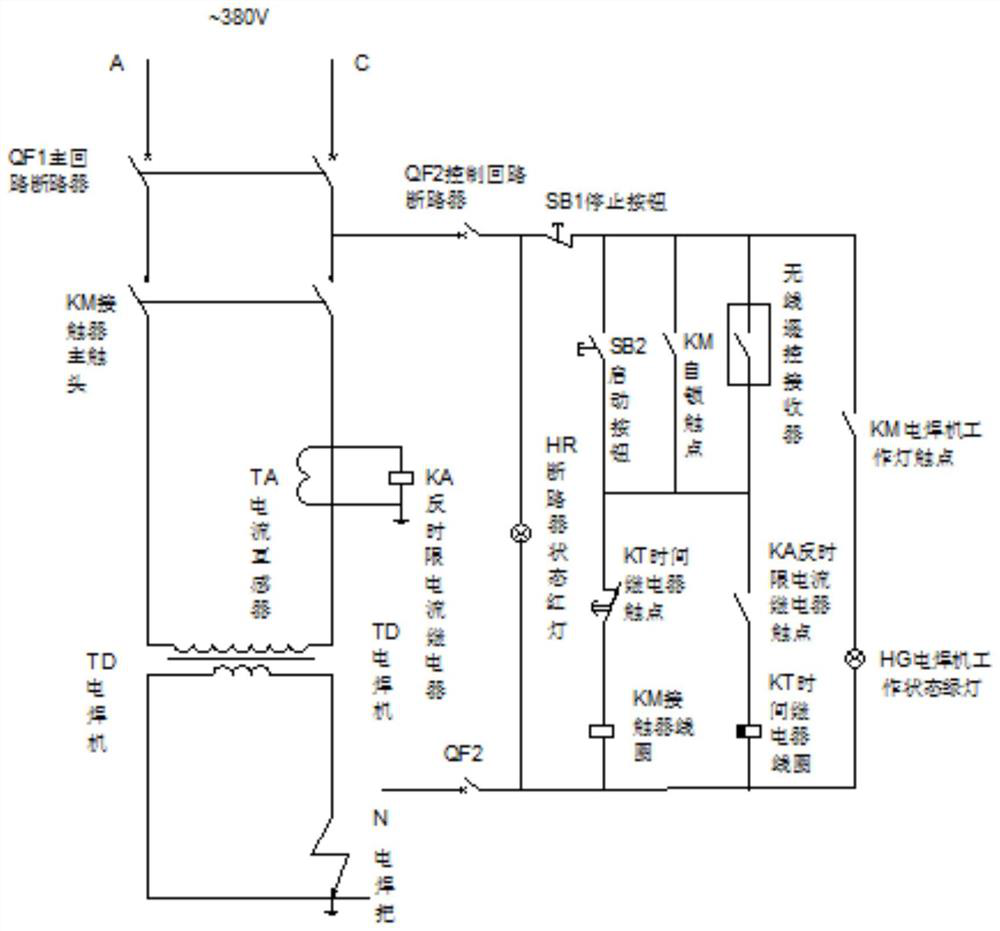

[0013] The power supply control system of an AC electric welding machine of the present disclosure includes a detection unit and a control loop. The detection unit is used to detect the primary current of the electric welding machine, and the control circuit is used to control the on-off of the main circuit of the AC electric welding machine. When the detection unit continuously detects that the primary current of the electric welding machine is no-load current for a set period of time, the control circuit cuts off the main circuit of the AC electric welding machine, so that the electric welding machine that has not been used for a long time will automatically stop. The electric welding machine can be woken up by the wireless remote control.

[0014] figure 1 A circuit diagram of an AC welding machine power supply control system provided by an embodiment of the present disclosure. like figure 1 As shown, the detection unit uses an undercurrent relay (inverse time limit curr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com