Device for removing large particles on membrane surface and membrane coating equipment

A technology with large particles and film surface, applied in the device, coating, electrical components and other directions of coating liquid on the surface, it can solve the problems of battery short circuit, affecting the service life and safety of the battery, etc., and achieve fast reaction speed and cutting effect. Good, accurate and reliable transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

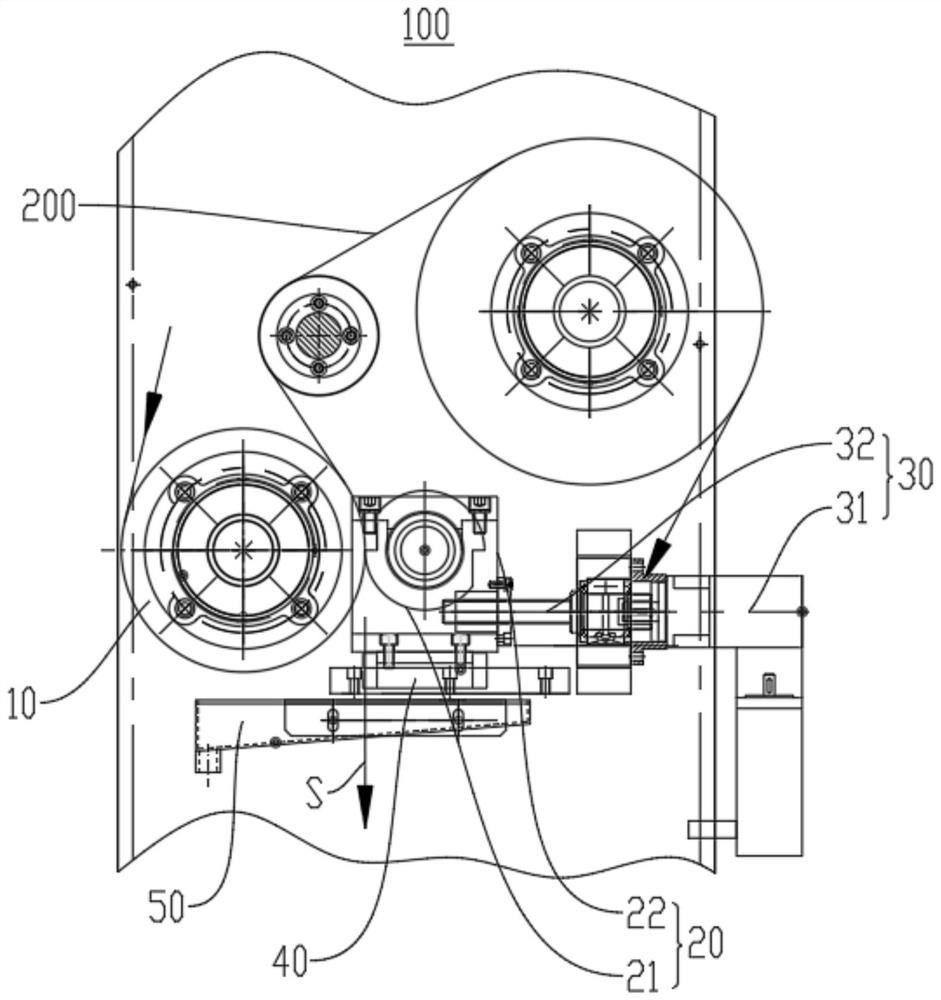

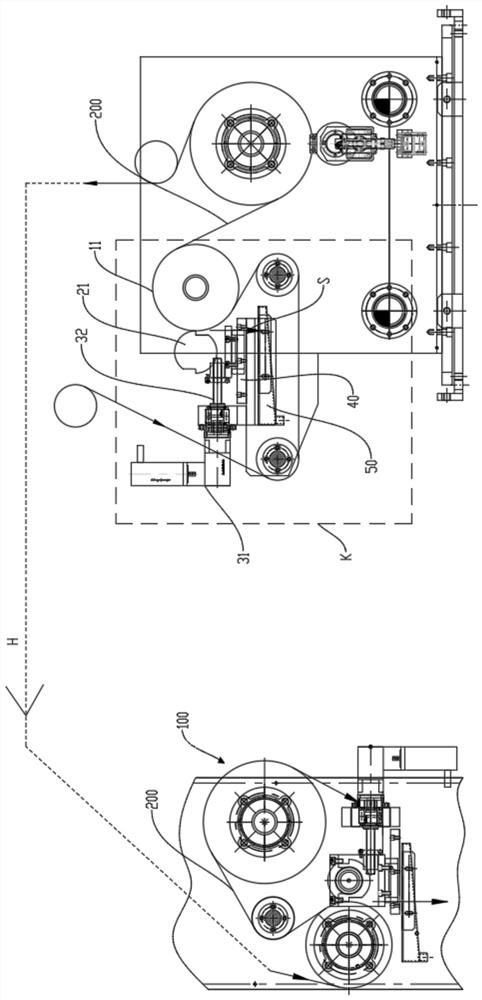

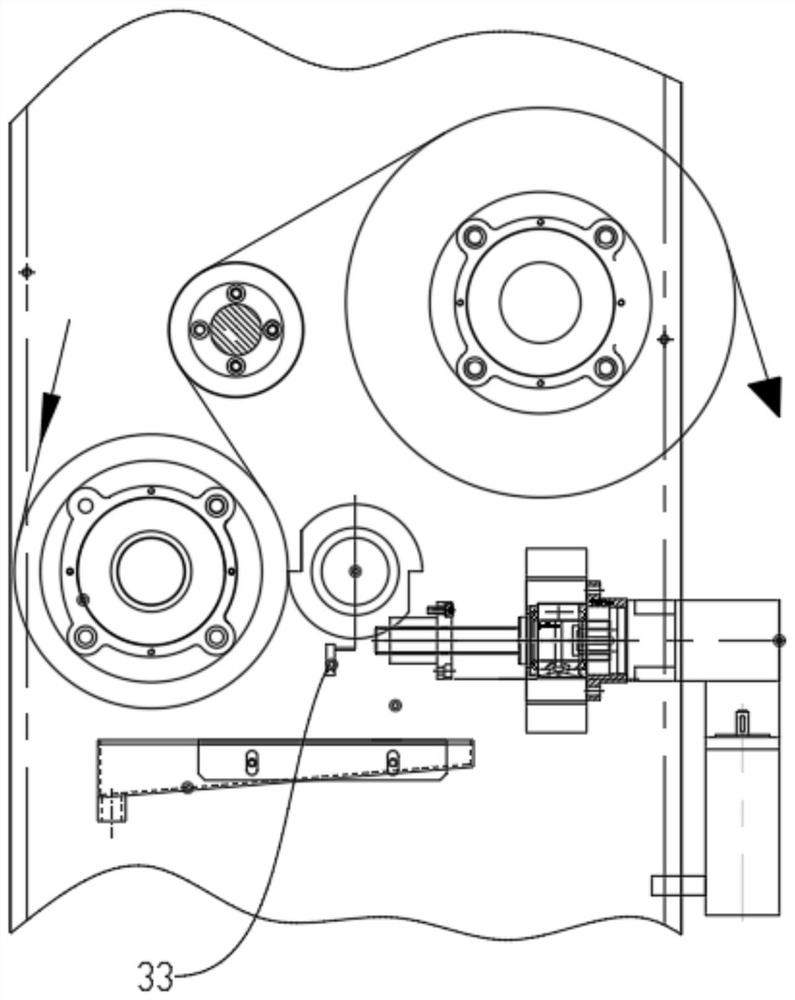

[0042] Please combine figure 1 , the embodiment of the present application provides a device 100 for removing large particles on the film surface, including: a bottom roller mechanism 10, a scraping roller mechanism 20 and a driving mechanism 30;

[0043] The bottom roller mechanism 10 is used to pull the diaphragm 200, and the output end of the drive mechanism 30 is connected to the scraping roller mechanism 20 and can drive the scraping roller mechanism 20 close to the bottom roller mechanism 10, so that the scraping roller 21 of the scraping roller mechanism 20 and the bottom roller mechanism 10 The spacing of the bottom rollers 11 is smaller than the particle diameter of the large particles. It should be noted that since the gap is very small, it appears that the scraping roller 21 and the bottom roller 11 are in contact in the figure, but in operation, there is a gap between the two. figure 1 The diaphragm 200 in the figure only shows its winding path, which does not mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com