LED display screen lamp panel fixing structure with front maintenance anti-falling function

A technology for LED display and front maintenance, which is applied to the installation of support structures, instruments, identification devices, etc., which can solve the problems of potential safety hazards, increase in the number and workload of maintenance personnel, and falling of display lamp panels, so as to achieve no hidden danger of falling , The fixing method is safe and reliable, and the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

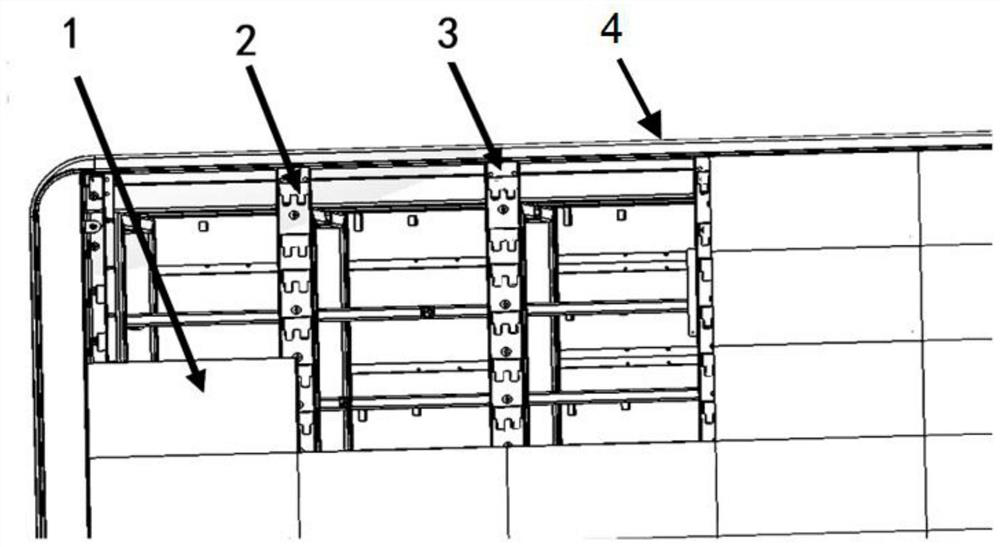

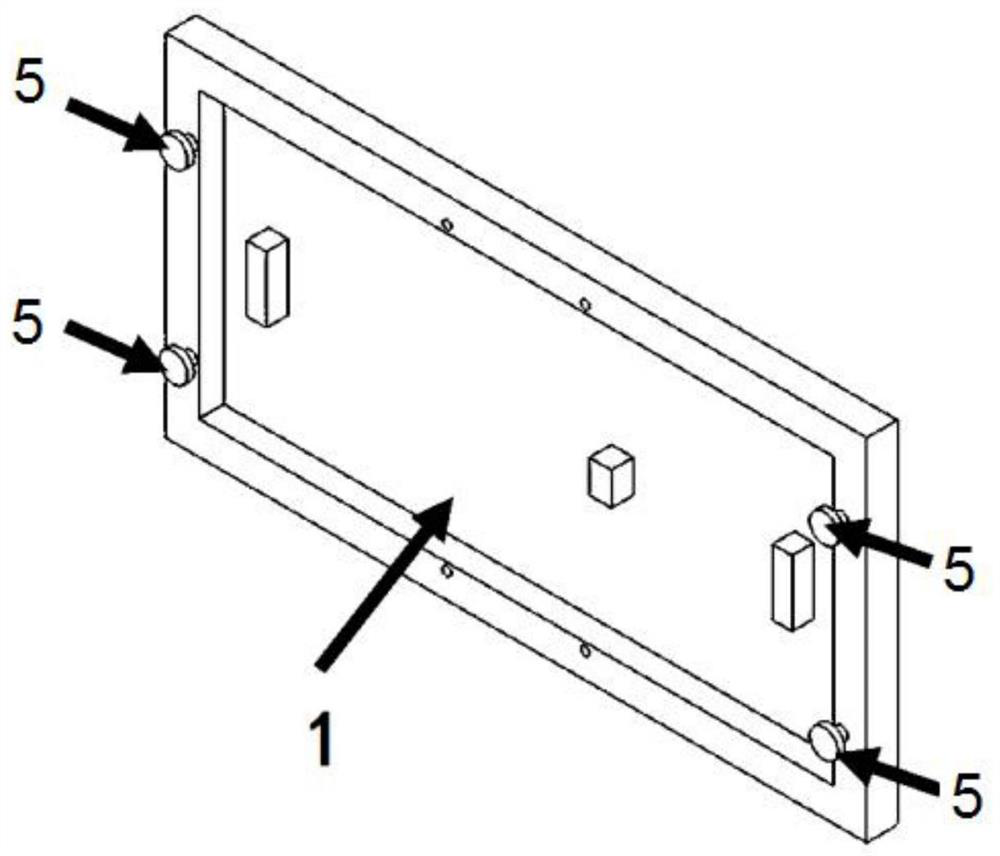

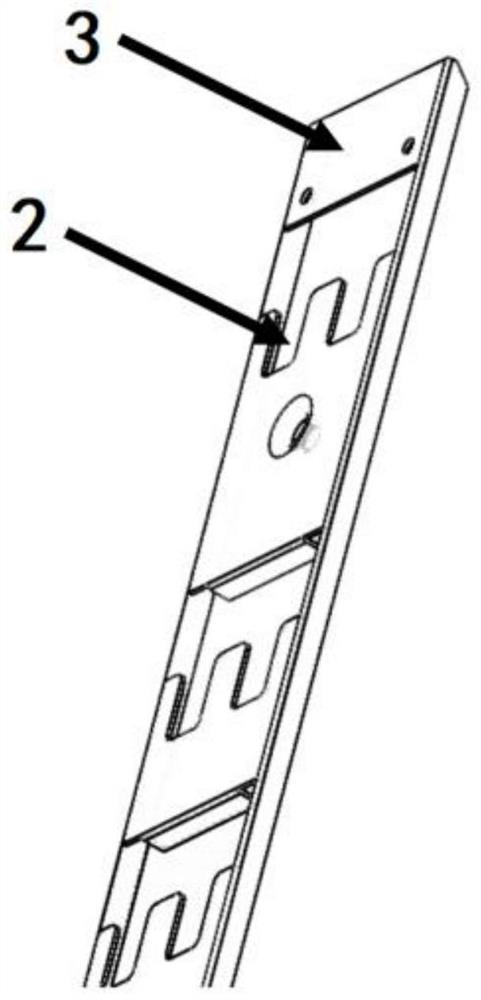

[0020] A LED display light panel fixing structure with front maintenance and anti-dropping functions, such as Figure 1 to Figure 4 As shown, it includes LED display lamp board 1, double-layer vertical bars 3 and LED main frame 4, and the double-layer vertical bars are multiple pairs, and many pairs of double-layer vertical bars are installed in parallel on the LED main frame. The vertical U-shaped fixing slots 2 are symmetrically formed on the surface of the vertical bar, and four magnet fixing parts 5 are symmetrically installed at both ends of the back of the LED display panel. In this embodiment, the magnet fixing parts are made of outer wire The specific installation method of the magnet is as follows: four threaded holes are symmetrically made on both ends of the back of the LED display panel, and an outer wire magnet is installed in each threaded hole,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com