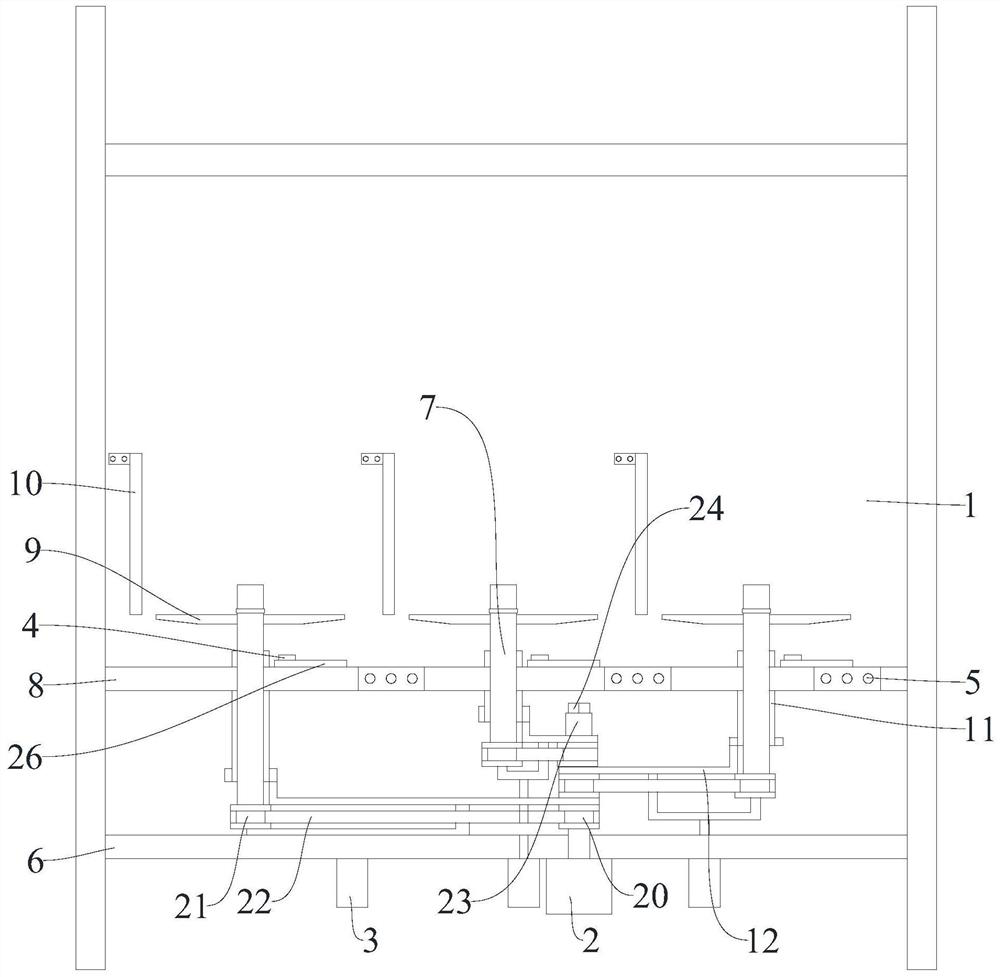

A structurally adjustable early warning device for twisting machines

An early warning device and twisting machine technology, applied in textiles and papermaking, etc., can solve problems such as the inability to monitor the surface entanglement amount of the yarn drum in real time, limited automation and safety, and the inability to adjust the height of the yarn drum specifications, etc., to achieve The effect of reducing the difficulty of manual operation, various monitoring ranges, and simple and convenient adjustment operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

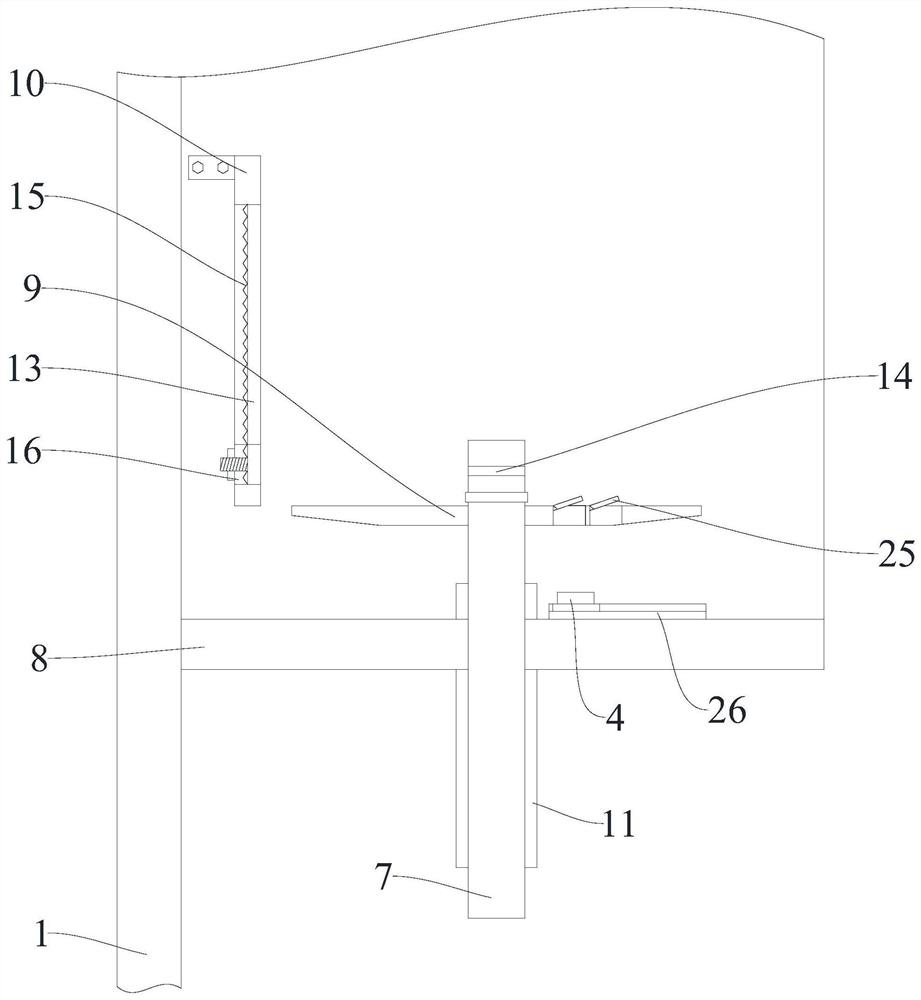

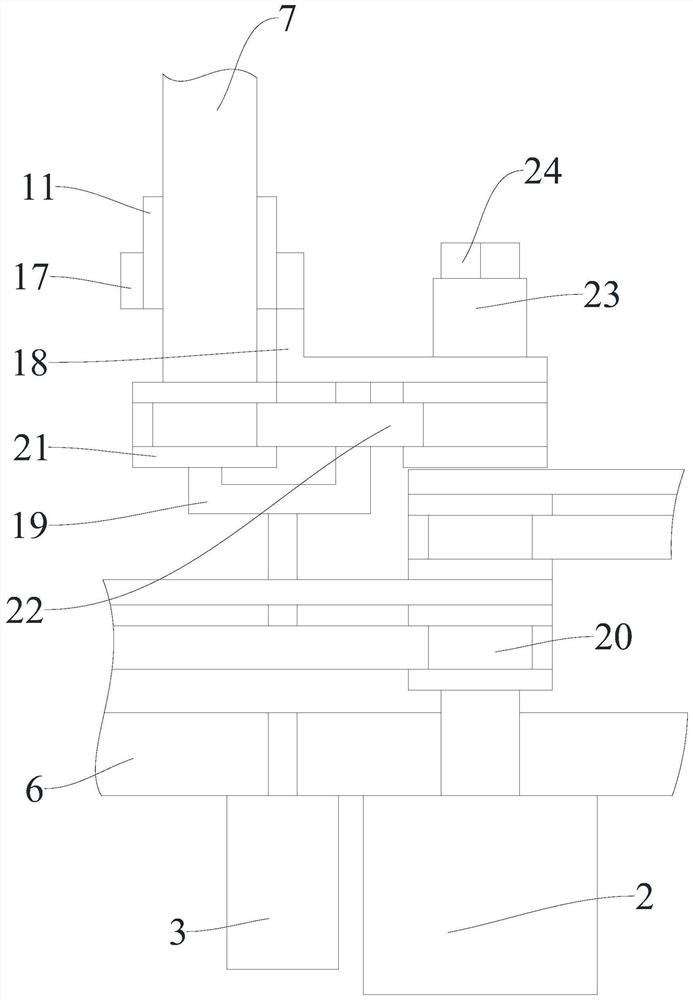

[0029] Embodiment: when the bobbin rotates, a lateral light-transmitting port is opened on the outer surface of the bobbin corresponding to the position of the annular reflective mirror 14, and when the infrared transceiver module 4 on the external mounting frame 10 emits infrared rays to the annular reflective mirror 14, it is then reflected back After receiving, it will control the drive motor 2 to shut down, which is convenient for people to change the bobbin, and then use the master control switch to restart the local drive motor 2. Under normal circumstances, the LED warning light 5 is green. When the yarn on the yarn bobbin leaves the elastic flip reflector 25, the elastic flip reflector 25 turns upwards and cannot reflect the infrared transceiver module 4 on the horizontal installation guide rail 26. At this time, the horizontal Place the infrared transceiver module 4 on the installation guide rail 26 to control the LED warning light 5 to switch the light to be red, remi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com