An easy-to-remove curved anti-wrinkle mandrel

A mandrel and pipe bending technology is applied in the field of easy-to-disassemble curved pipe wrinkle-proof mandrels, which can solve the problems of easy wear of the pipe wall and difficult core pulling, and achieve the effects of not easy to break, convenient for core pulling, and simplifying the structure of the mandrel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

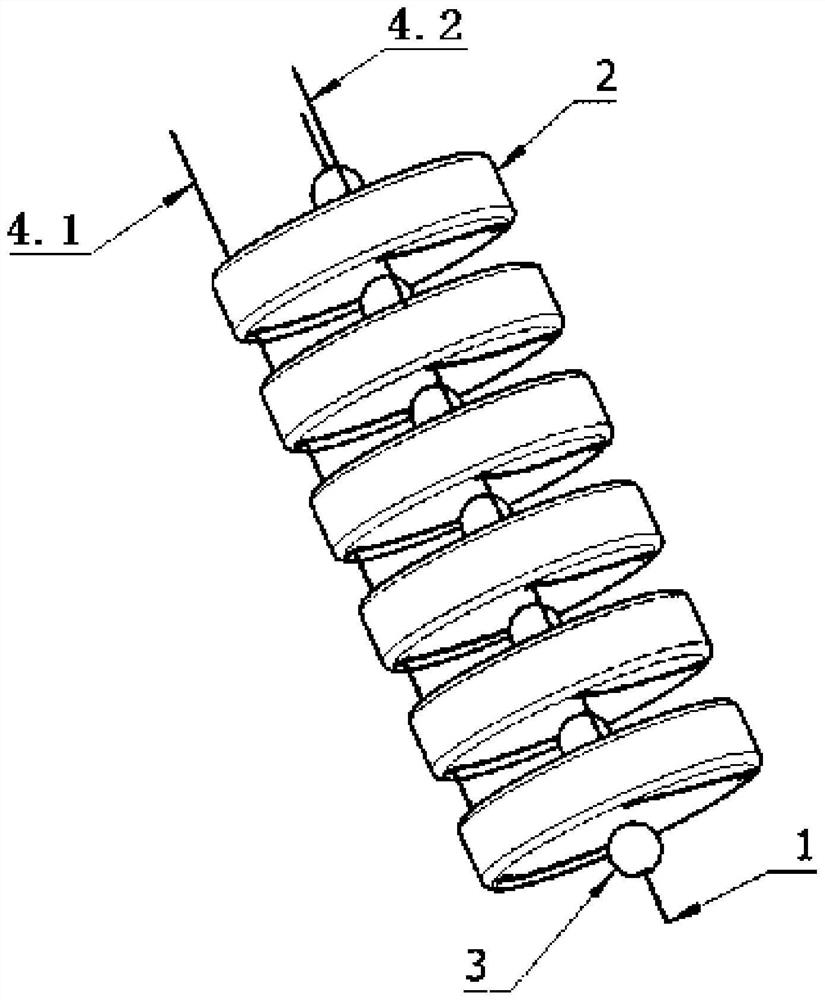

[0030] like figure 1 , figure 2 As shown, the present invention is an easy-to-detach elbow wrinkle-proof mandrel, including a limiting core wire 1, a plurality of mandrel elements 2, and a plurality of spacer beads 3. In this embodiment, six mandrel elements 2 and Seven spacer bead 3 illustrate.

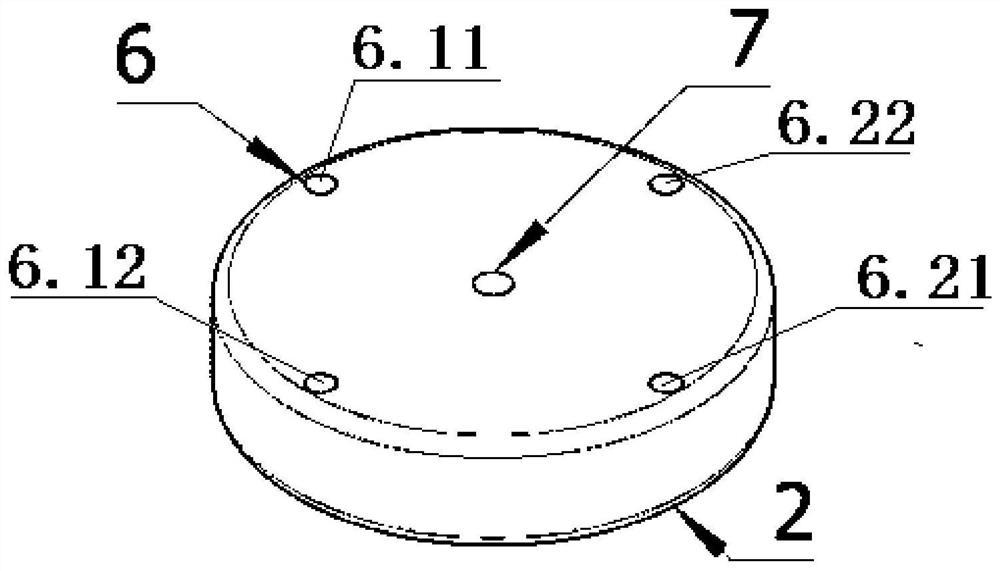

[0031] like image 3 , Figure 4 As shown, the center of each mandrel element 2 is respectively provided with a through hole 7 passing through the axial direction of the mandrel element 2, and the center of each limiting ball 3 is respectively provided with a through hole 8, and the six mandrel elements 2 are arranged in sequence. The same number of spacer bead 3 is arranged between adjacent mandrel elements 2 at intervals. In this embodiment, the number of spacer bead 3 between adjacent mandrel elements 2 is one. There are five limiting balls 3 clamped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com