Actuator of a nuclear reactor control and protection system

A technology of actuating mechanism and protection system, applied in the field of actuating mechanism of a system for controlling and protecting a nuclear reactor, can solve problems such as rod and working part bayonet connection and disconnection, stopper failure and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

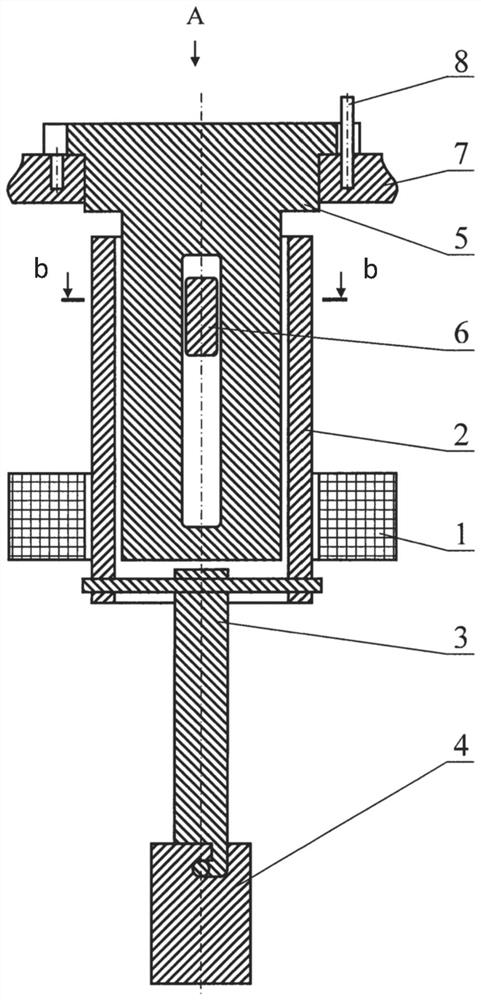

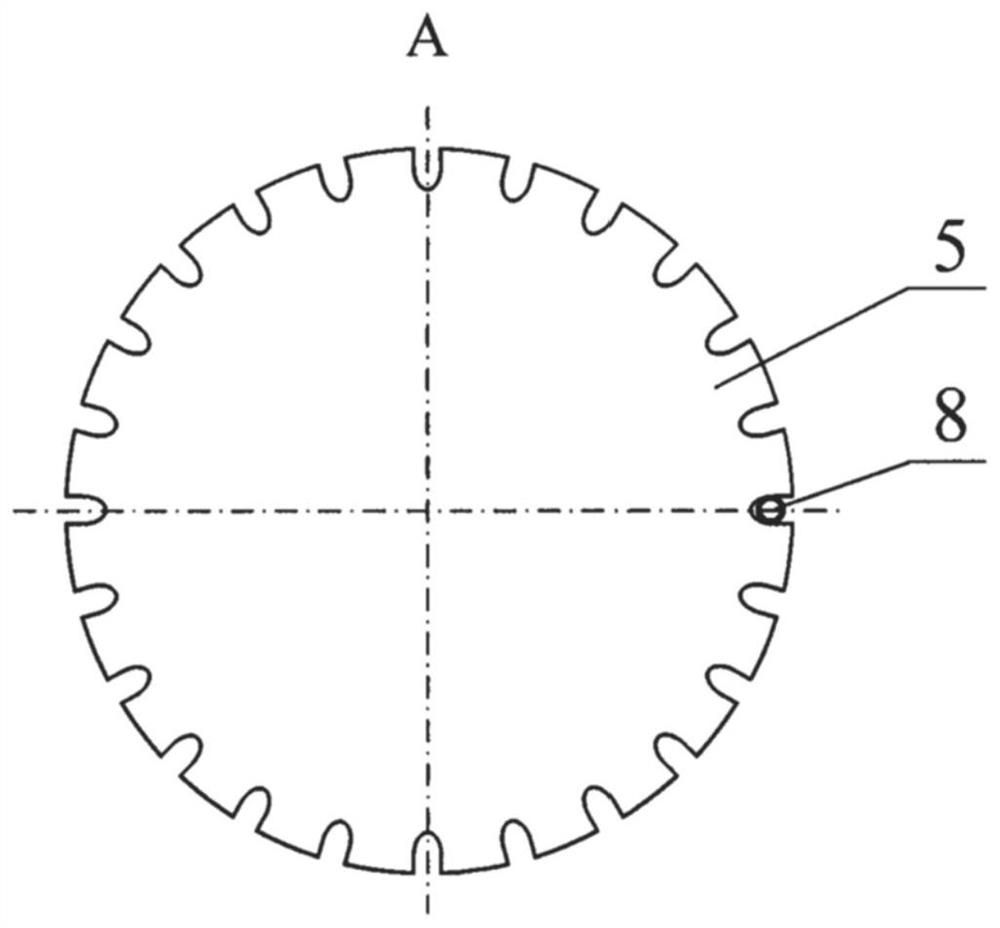

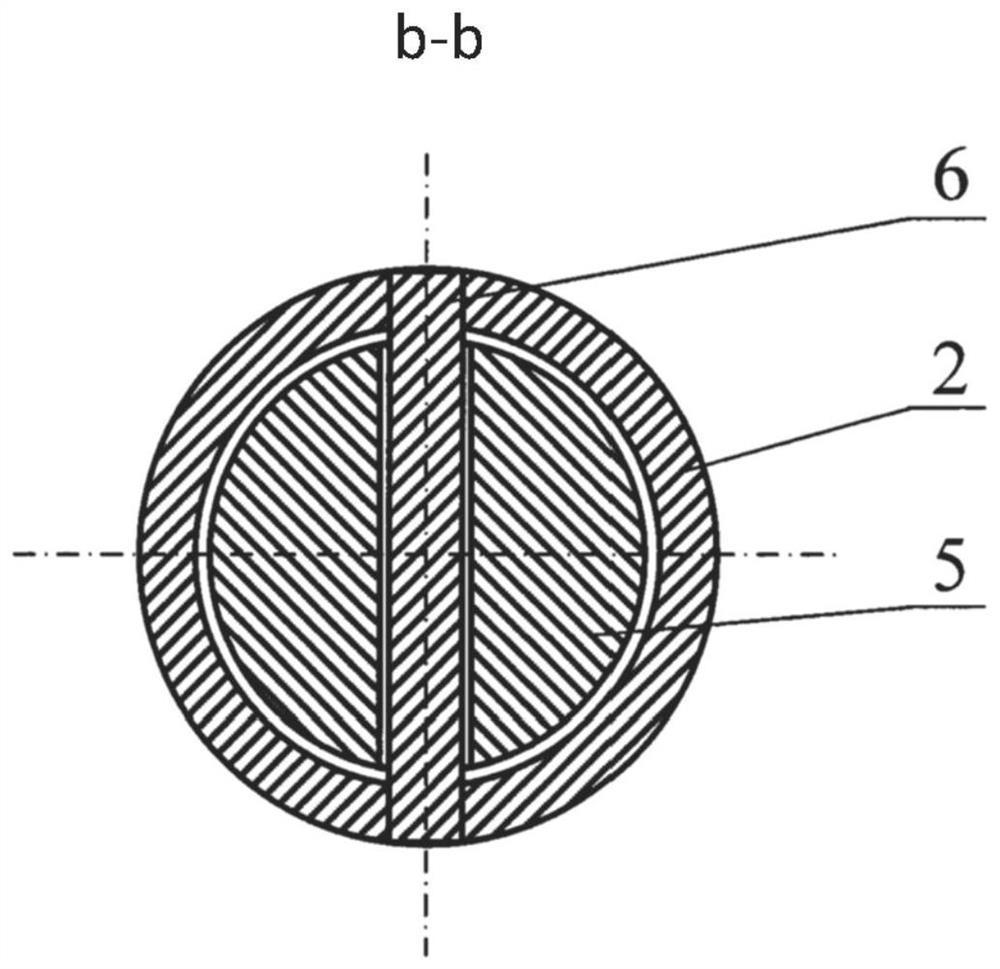

[0013] The actuation mechanism of the nuclear reactor control and protection system consists of: a linear stepper motor 1 with an armature (anchor) 2 in the form of a vertical tube; a rod 3 mounted coaxially with the armature 2 and rigidly connected to the armature, to allow joint / joint vertical displacement and rotation around a common vertical axis; and a lock preventing spontaneous rotation of the rod 3 . The lower end of the rod 3 is connected to the working part 4 by an L-shaped bayonet joint. The locking piece preventing the spontaneous rotation of the rod has a guide part 5 , a transverse piece 6 , a fixed (immovable) ring 7 and a vertical pin 8 . The guide portion 5 is provided with a flange at its upper end. The lower part of the guide 5 is located inside the armature 2 . The inner surface of the flange of the guide rests on the fixing ring 7 and is centered about its inner circumference. In the free lower part of the guide 5 there is a longitudinal through-slot in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com