Laboratory model test displacement meter fixing device and mounting method

An indoor model and fixing device technology, applied in the field of tunnel engineering, can solve the problems of affecting the accuracy of test results, unable to truly reflect the tunnel displacement, unable to accurately measure the tunnel convergence change and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

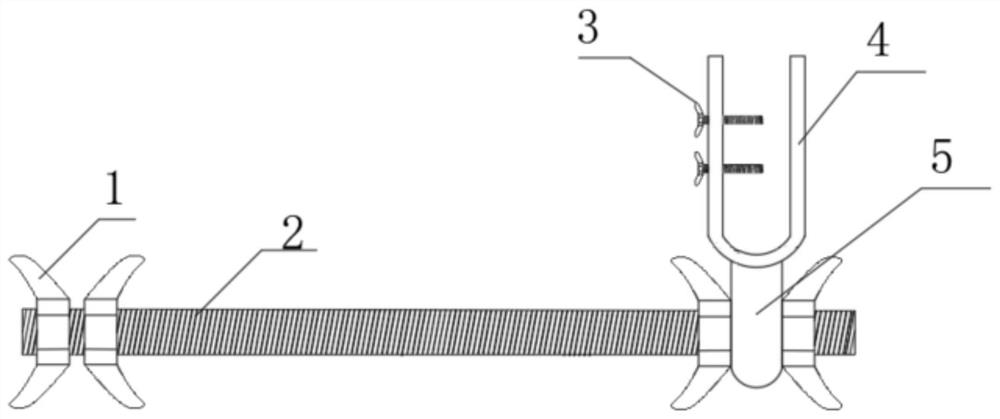

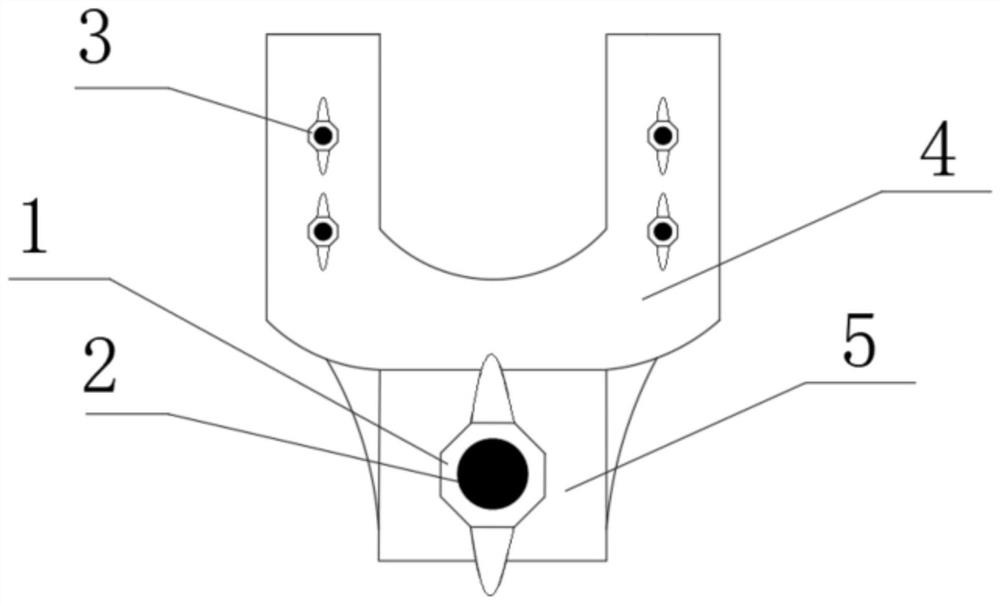

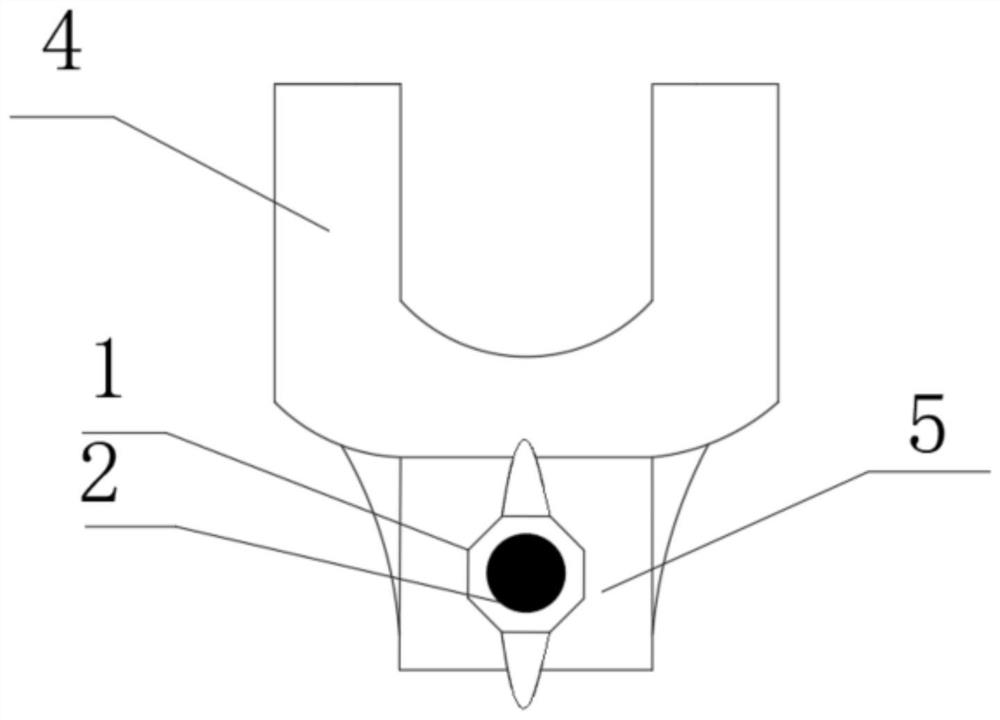

[0038] Embodiment 1 of the present application provides an indoor model test displacement meter fixing device, including a main structure and ancillary devices, such as Figure 1-7 shown.

[0039] The main structure includes a screw 2 and a fixture, wherein the fixture is mainly composed of a clip 4, a clip seat 5 and a screw socket 6, the clip 4 and the clip seat 5 are welded to form a whole, and the clip seat 5 is provided with a screw socket 6. The clamp and the screw rod 2 are made of inelastic material, which may be metal material, and the length of the screw rod 2 can be freely selected and manufactured according to needs. The clip 4 is made of U-shaped steel sheet, and the U-shaped steel sheet is provided with a card slot, which does not affect the lead-out of the displacement meter signal line while clamping the displacement meter. Screw jack 6 can adopt smooth hole also can adopt threaded hole, as long as can be fastened on the screw rod 2 and get final product.

...

Embodiment 2

[0043] Embodiment 2 of the present application provides a method for installing an indoor model test displacement gauge fixing device, including the following steps:

[0044] 1) Tunnel model drilling: Before the test starts, holes are drilled at the corresponding positions of the model tunnel according to the test design.

[0045] 2) Fixing of the displacement meter: First, use a pair of displacement meter fixing devices to clamp the ears on both sides of the displacement meter 7 with clips 4, and then tighten the claw fastening screw 3 to fix the displacement meter 7.

[0046] 3) Installation of the displacement meter: Remove the horn nut 1 on the outside of both ends of the screw rod 2, adjust the position of the displacement meter 7, insert the screw rod 2 into the drilled hole from the inside of the tunnel, and screw the horn nut 1 on from the outside of the tunnel , fix the screw rods on both sides on the tunnel wall 8, and then the displacement gauge 7 can be fixed.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com