Waterproof structure at abutted seam of prefabricated light-steel keel composite wallboards

A technology of composite wall panels and light steel keels, which is applied in the direction of walls, building components, building structures, etc., and can solve problems such as looseness, engineering hidden dangers, and corrosion of steel components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

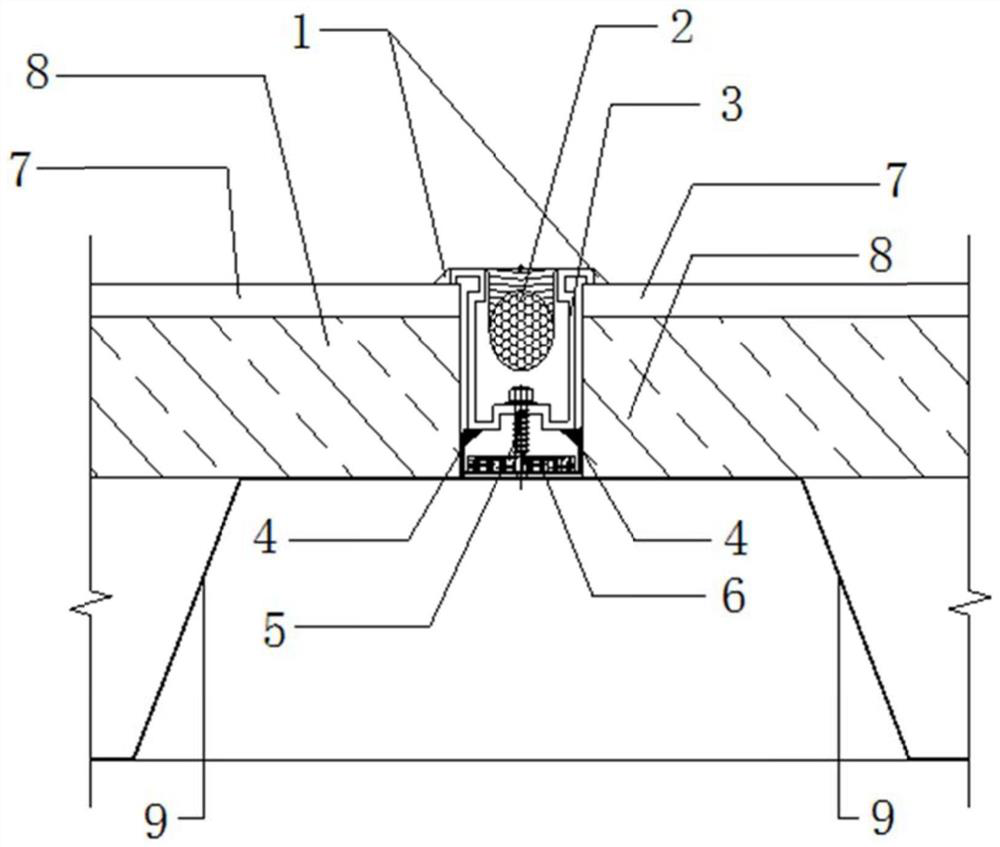

[0025] Such as figure 1 , a waterproof structure of assembled light steel keel composite wall panels, including a number of external wall panels composed of anti-crack mortar 7, XPS board 8 and profiled steel plate 9, the wall panels are spliced to form horizontal and vertical waterproof joints, The depth of the horizontal and vertical waterproof joints is 1 / 3-1 / 4 of the thickness of the light steel keel composite wallboard, and the waterproof joints in the two directions are sealed with the same cavity waterproof structure.

[0026] The waterproof structure is a cavity waterproof structure, and a sealed box 3 is arranged in the cavity waterproof structure; the upper part of the sealed box 3 is provided with an open opening with an edge, and the edge of the upper part of the sealed box 3 is connected with the light steel keel composite wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com