Feeding device for squeezer

A technology of feeding device and press, which is applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problem that the suction fan cannot better control the feeding speed, adjust and control the feeding speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

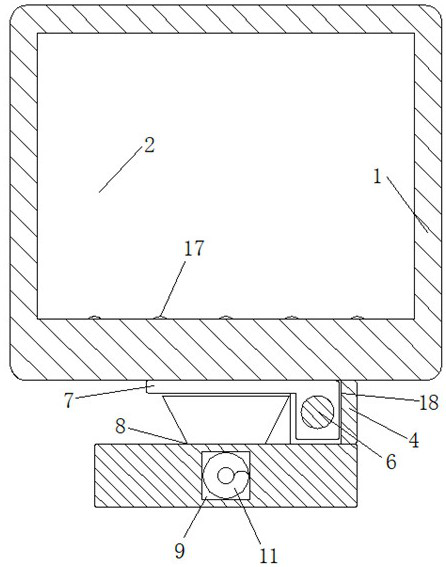

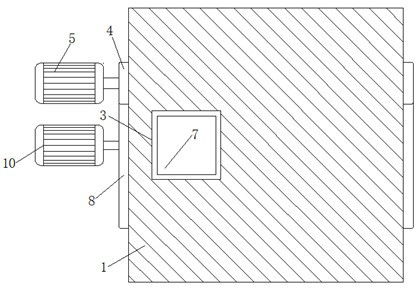

[0020] Such as Figure 1-3 As shown, the present invention provides a feeding device for a press machine, which includes a box body 1, a material trough 2 is provided inside the box body 1, and a discharge chute is provided at one end of the trough wall at the bottom of the material trough 2 3. A connection block 4 is fixedly connected to the lower surface of the box body 1. A groove 18 is provided on the surface of the connection block 4. One end of the connection block 4 is provided with a first motor 5. The output of the first motor 5 The end passes through the outer wall of the connecting block 4 and extends into the groove 18, and the end of the first motor 5 located in the groove 18 is fixedly connected with a screw mandrel 6, and the end of the screw mandrel 6 away from the first motor 5 is connected to the groove 18. The groove wall is connected by bearing rotation, and an L-shaped baffle 7 is threaded on the rod wall of the screw rod 6 corresponding to the position of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com