Full-automatic highway-railway free conversion driving wheel

A driving wheel, fully automatic technology, applied in the direction of wheels, transportation and packaging, vehicle components, etc., can solve problems such as increasing the volume of the whole machine and increasing the complexity of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

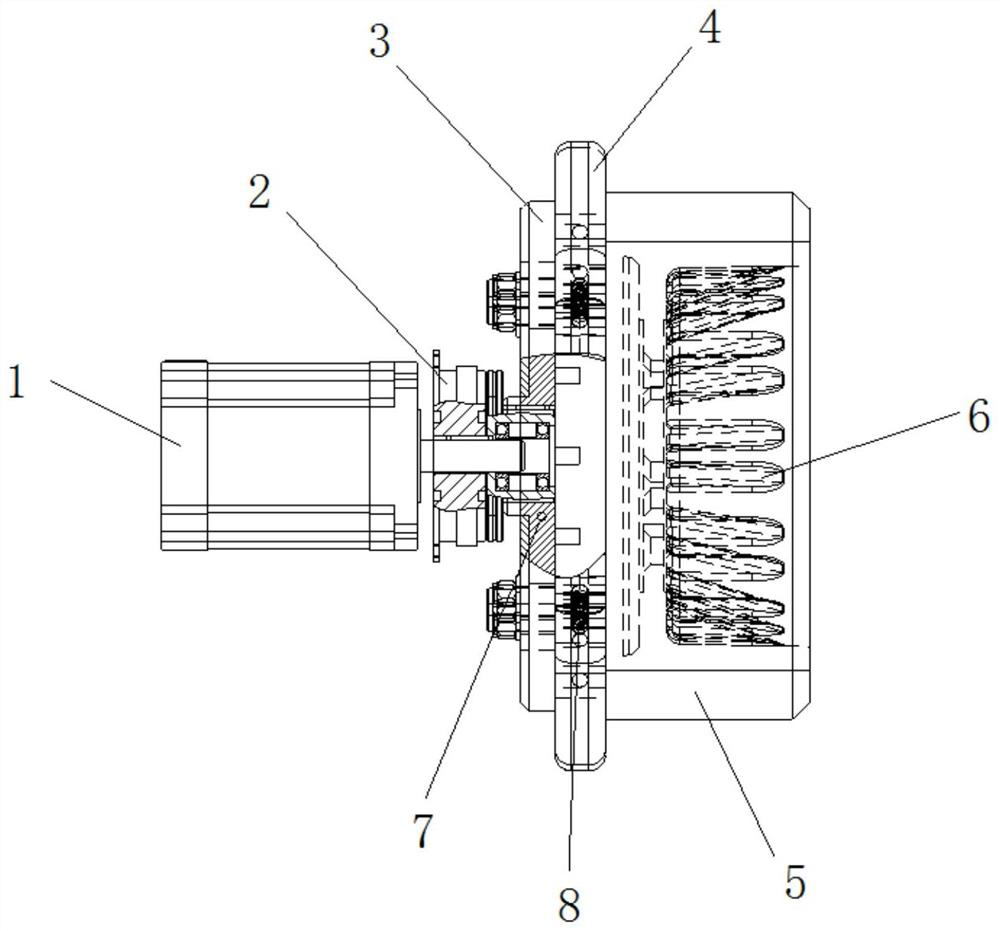

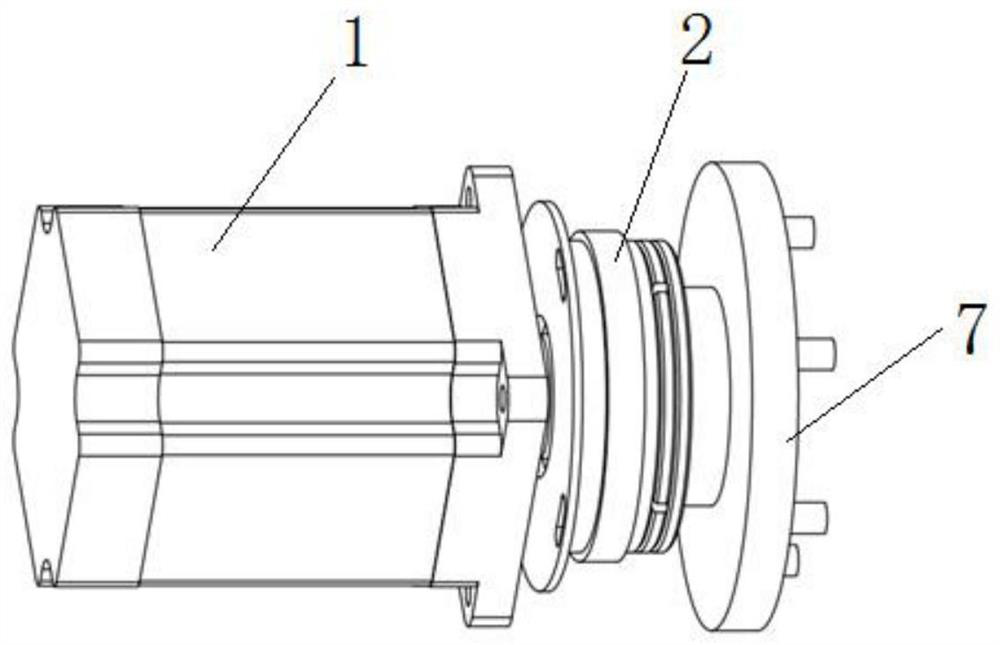

[0032] Specific implementation mode one: see Figure 1-13 This embodiment will be described. The fully automatic road-rail free switching driving wheel described in this embodiment includes a main driving part and a driving wheel, the main driving part drives the driving wheel to rotate, and the driving wheel can switch between road mode and railway mode;

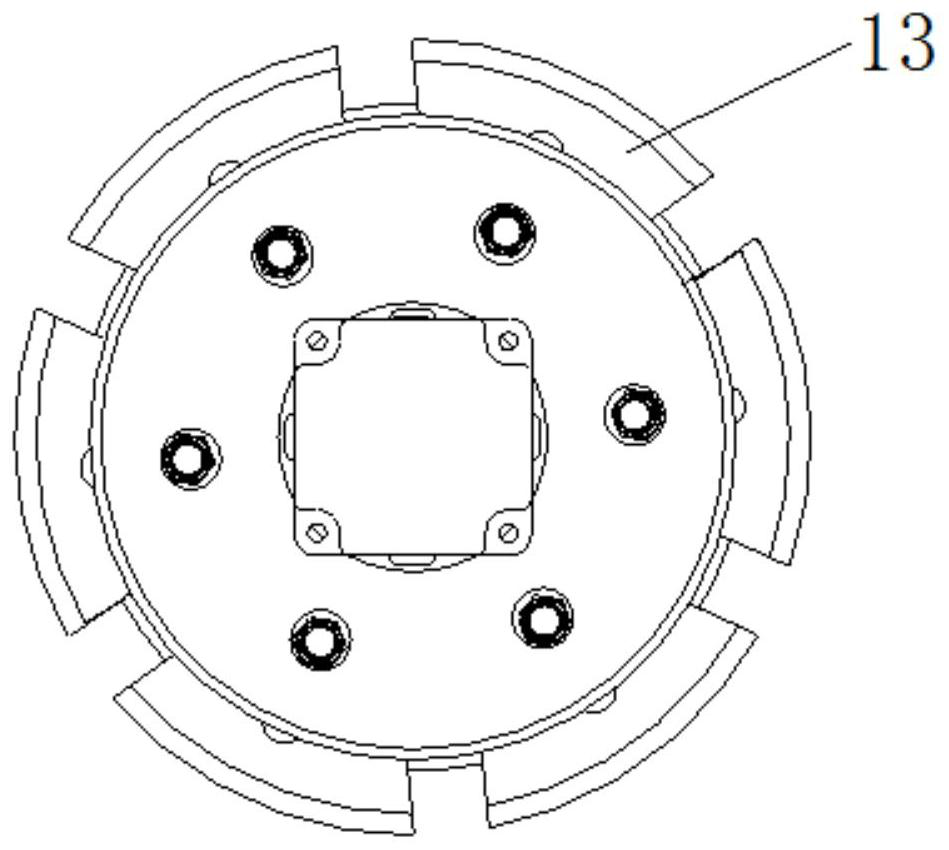

[0033] The driving wheel comprises a pressure plate 3, a wheel rim 4, a wheel surface 5, a wheel hub 6, six deadbolt assemblies 8 and a guide column 9, and the wheel hub 6 outer periphery is wrapped with a wheel surface 5, and the wheel hub 6 is installed with six guide columns 9, the upper part of the guide column 9 is a threaded column, which is connected with the pressure plate 3 and tightened by screws to play a locking role. The threaded column on the top of the guide column 9 is fixedly connected, and six dead bolt assemblies 8 are respectively installed in the six guide columns 9,

[0034] The wheel rim 4 includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com