Horizontal paper cup handle sticking machine

A paper cup and horizontal technology, which is applied in the field of horizontal paper cup sticking machines, can solve the problems of high labor intensity, low production efficiency, and affect the neatness of workers, so as to improve processing efficiency and quality, reduce labor intensity, and improve aesthetics. The effect of degree and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

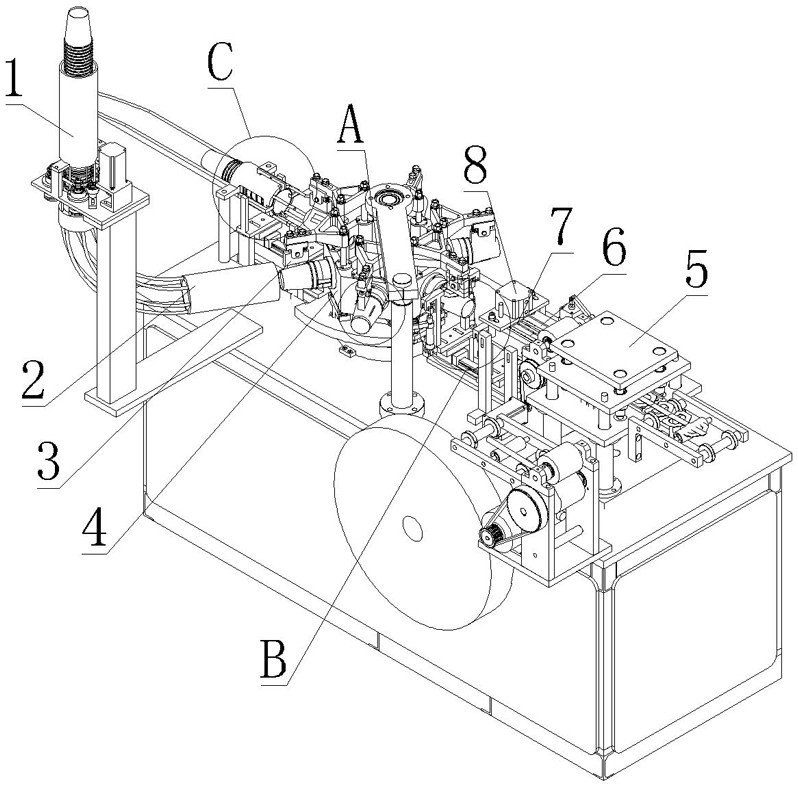

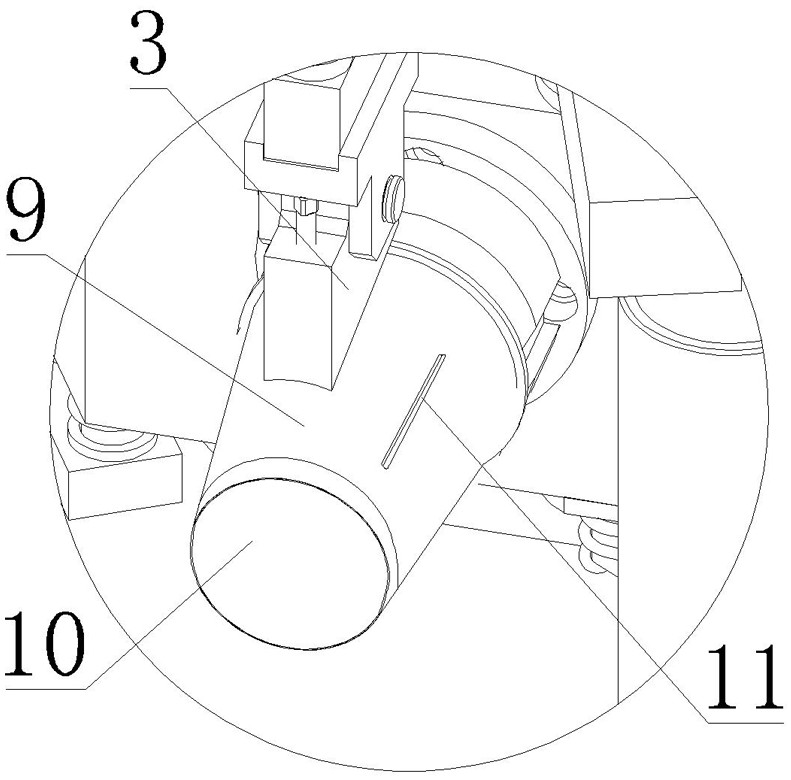

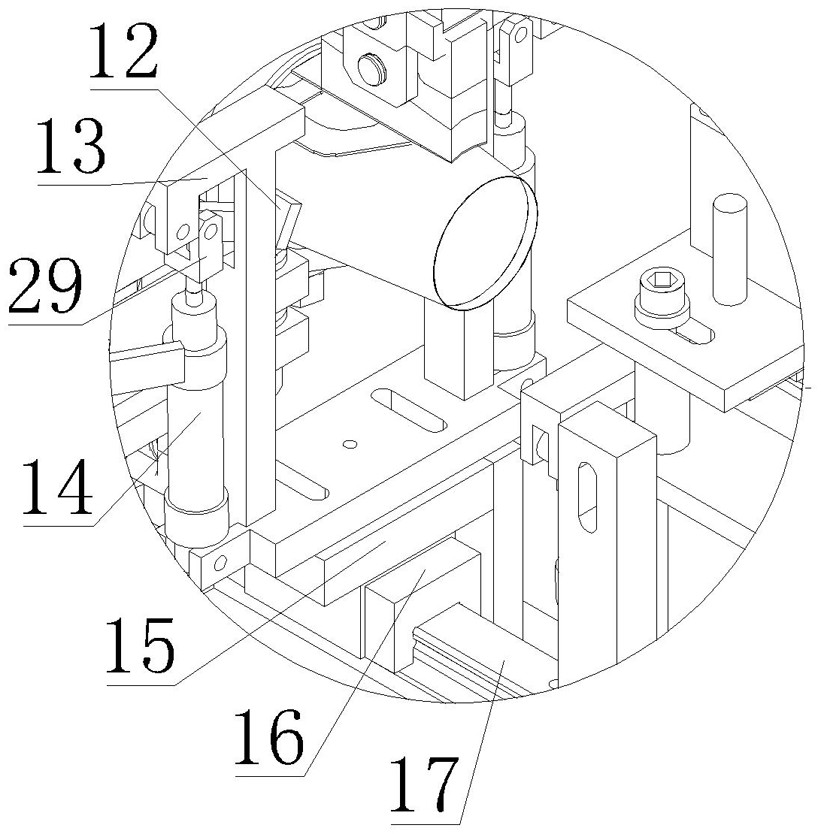

[0023] As shown in the figure, the horizontal paper cup sticking machine disclosed in the present invention includes a paper cup conveying mechanism and a turret 4. Specifically, the paper cup conveying mechanism includes a paper cup stacking rack 1, and a paper cup conveying path 2 is arranged at the bottom of the paper cup stacking rack 1 , the outer side wall of the turret 4 is surrounded by a cup mold 9 , and the discharge port of the paper cup conveying path 2 can be aligned with the cup mold 9 . Along the rotation path of the turret 4, a paper cup positioning and rotating mechanism and a cup handle forming and conveying mechanism are sequentially arranged. Specifically, the paper cup positioning and rotating mechanism includes a rotating pressure head 22, and the rotating pressure head 22 is connected with the driving motor 25. On the frame 23, the moving frame 23 is connected with the horizontal drive assembly, and the horizontal drive assembly includes a first swing blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com