Self-locking mute roller pin wrench

A self-locking, needle-rolling technology, which is applied in the field of wrenches, can solve the problems of large rotation angle and low efficiency, and achieve the effect of reducing the rotation angle, reducing the contact gap, improving the accuracy and the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

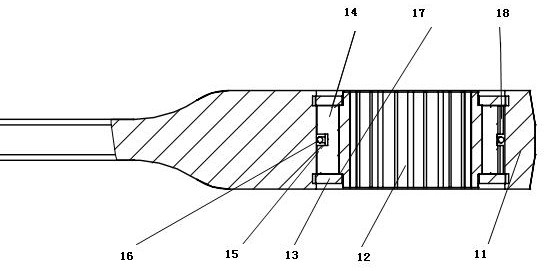

[0027] The specific technical solution of the present invention will be described below with reference to the drawings. The orientation is described with the inner hole of the annular body 11 in a horizontal state in the vertical direction. For example, the vertical direction refers to the vertical direction of the inner hole of the annular body 11.

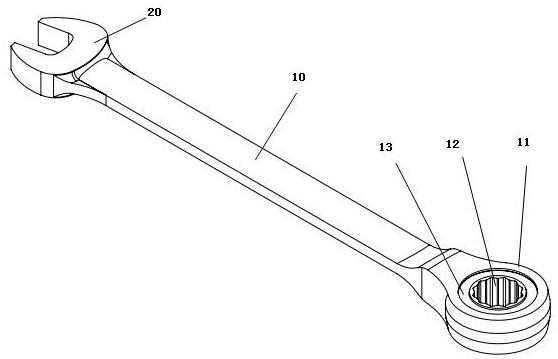

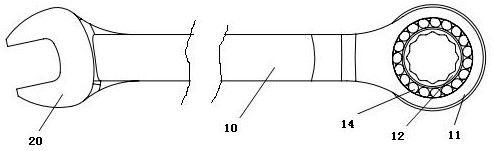

[0028] The positive effect of the present invention is a self-locking mute needle roller wrench, figure 1 Is a schematic diagram of the three-dimensional structure of the present invention, figure 2 It is a schematic diagram of the clothing structure without the ring card 13, image 3 It is a schematic diagram of the cross-sectional structure along the longitudinal direction of the ring body 11. Figure 4 Is the end view of the needle roller in polar coordinates, Figure 5 It is a schematic diagram of the structure of the end surface of the needle roller. The silent needle roller wrench includes a wrench handle 10, the end of the ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com