Cam bearing cap tapping device and application method thereof

A technology of cam bearings and bevel gears, which is applied in the field of cam bearing cap tapping devices, can solve the problems of low degree of automation, difficulty in controlling the depth, and inapplicable batch processing of products, etc., so as to improve work efficiency, facilitate post-cleaning, and have a reasonable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

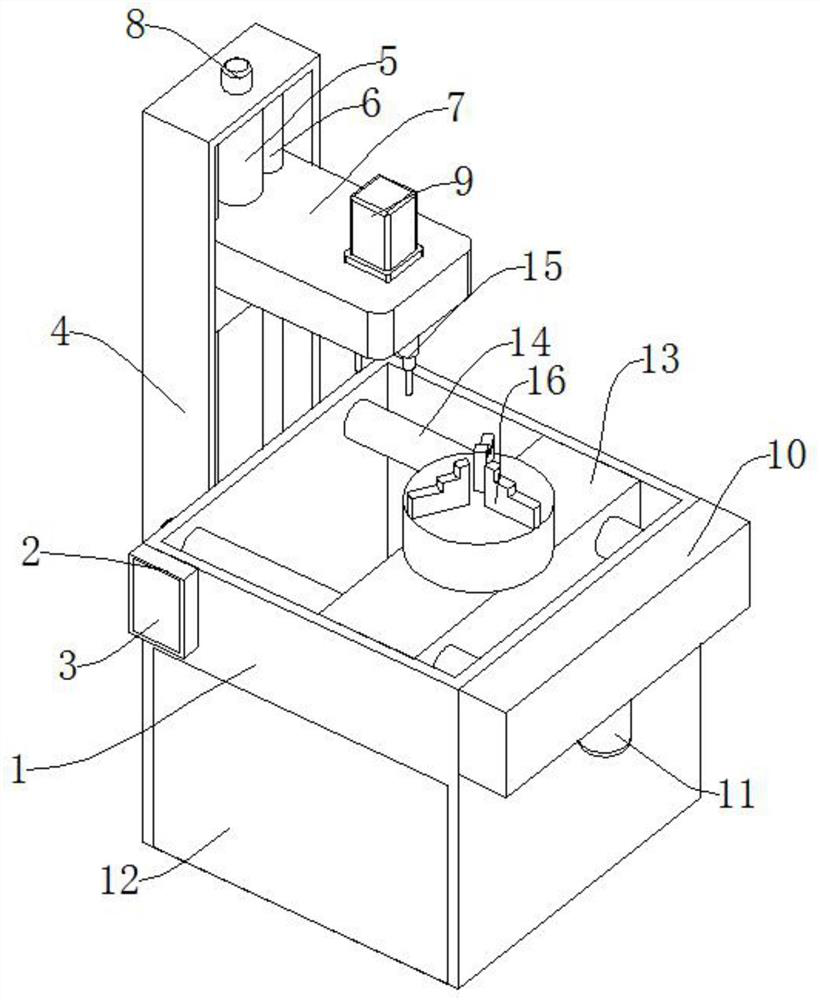

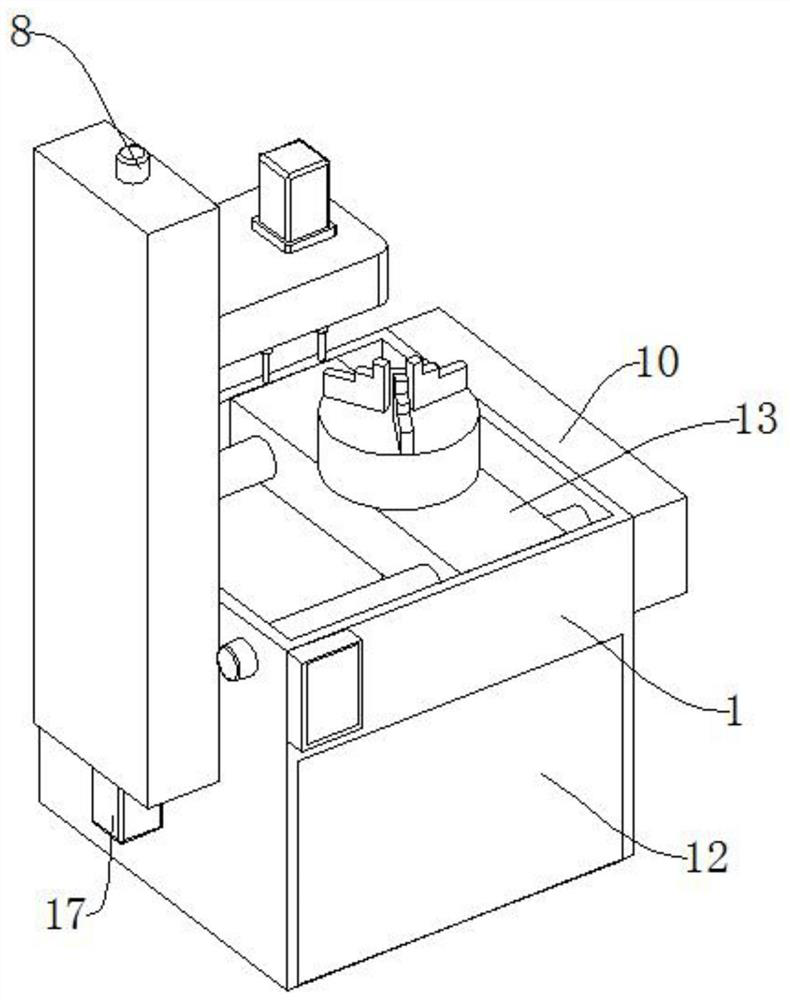

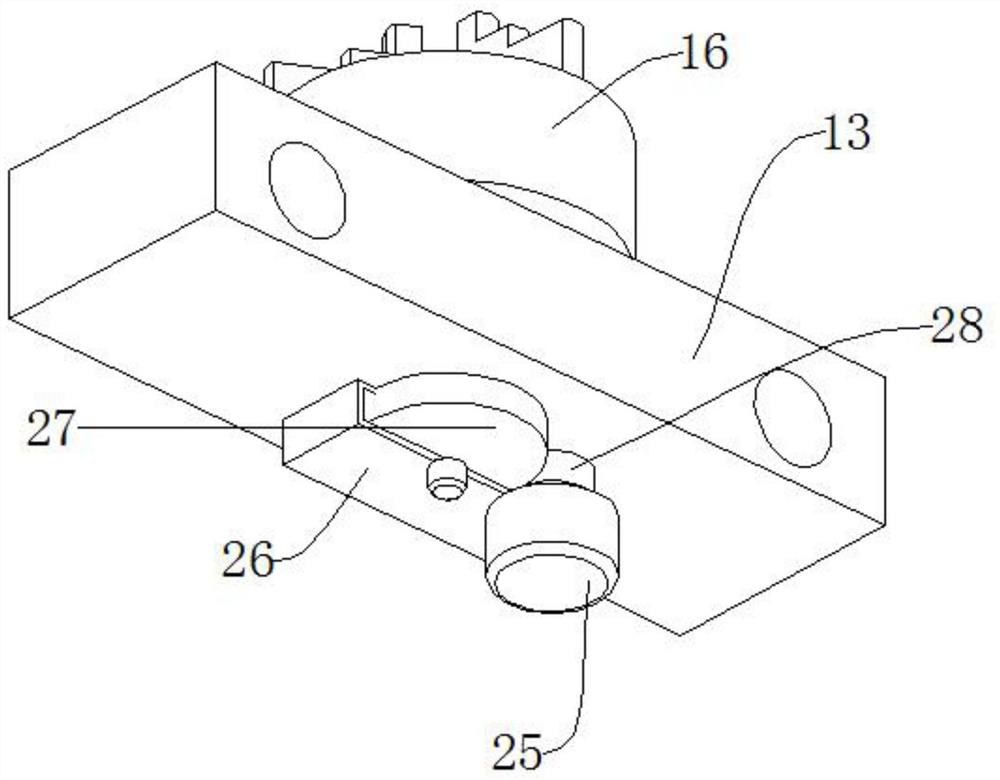

[0050] like Figure 1-Figure 7 As shown, a cam bearing cap tapping device includes a device housing 1, a lifting frame 7, a moving frame 13, and a recovery box 12. The front end of the device housing 1 is provided with a control box 2, and the control box 2 plays a protective role. The device housing The body 1 acts as a bearing, the control box 2 is provided with a control panel 3, the control panel 3 acts as a control, and the control box 2 is provided with a controller 24 inside;

[0051] The recovery box 12 is arranged on the inside of the device housing 1, and the recovery box 12 plays a collection role. The side of the device housing 1 is provided with a support column 4, and the support column 4 plays a supporting role. The lower end of the support column 4 is provided with a second servo motor 17. Two servo motors 17 play the role of energy supply, the inner side of the support column 4 is provided with a lifting screw 5, the front and rear sides of the lifting screw 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com