Labor-saving tossing pot and working method

A pot body and frying technology, which is applied to the structure of cooking utensils, cooking utensils, household utensils and other directions, can solve the problem that the bracket affects the appearance of the pot, and achieve the effect of saving design space, easy to master, and fewer accessories.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

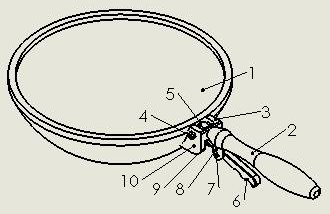

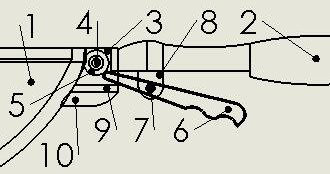

[0032] Such as figure 1 2, the handle; 3, the pot body is connected to the lug; 4, the connecting shaft; 5, the handle is connected to the lug; 6, the lever handle; 7, the lever connecting shaft; 8, the lever lug ; 9, the pot body paddle; 10, the limit device and other components.

[0033] Such as figure 2 As shown, the pot body 1 and the handle 2 are movably connected through the connecting shaft 4 through the pot body connecting lug 3 and the handle connecting lug 5, with the lever connecting shaft as the 7 fulcrums, a lever 6 is installed on the connecting shaft, and the front end of the lever 6 is connected to the pot. The plectrum 9 of body 1 contacts, and the plectrum 9 of pot body is fixed on the pot body, and the other end is a lever handle.

[0034] working principle:

[0035] In the present invention, the lever is used to pry the pot body to save labor, the lever connecting shaft 7 is used as the support point, the lever handle 6 is held, the front end of the lev...

Embodiment

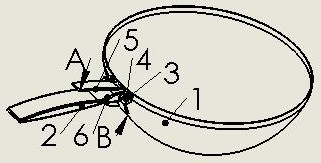

[0039] Such as image 3 As shown, the method is composed of 1. pot body; 2. handle; 3. pot body connecting lug; 4. connecting shaft; 5. L-shaped lever handle; 6. limit device.

[0040] Such as Figure 4 As shown, the pot body 1 and the handle 2 are movably connected through the connecting shaft 4 through the pot body connecting lug 3 and the handle lug 2, with the connecting shaft as the 4 fulcrums, an L-shaped lever 5 is installed on the connecting shaft 4, and the L-shaped lever 5 , B end is in contact with pot body 1.

[0041] working principle:

[0042] The present invention uses the lever to pry the pot body to save labor. Because the pot body 1 and the handle 2 are movable links, and the connecting shaft 4 is the support point, the A end of the L-shaped lever handle is held, and the B end of the L-shaped lever pushes the pot body to move the pot body 1. Pry up and let go of the L lever handle 5. The pot body falls back down under the action of gravity, so that the fry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com