River snail tail batch removing equipment for river snail processing

A field snail, batch technology, applied in the field of field snail tail batch removal equipment for field snail processing, can solve the problems of low work efficiency and labor, and achieve the effect of high work efficiency and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

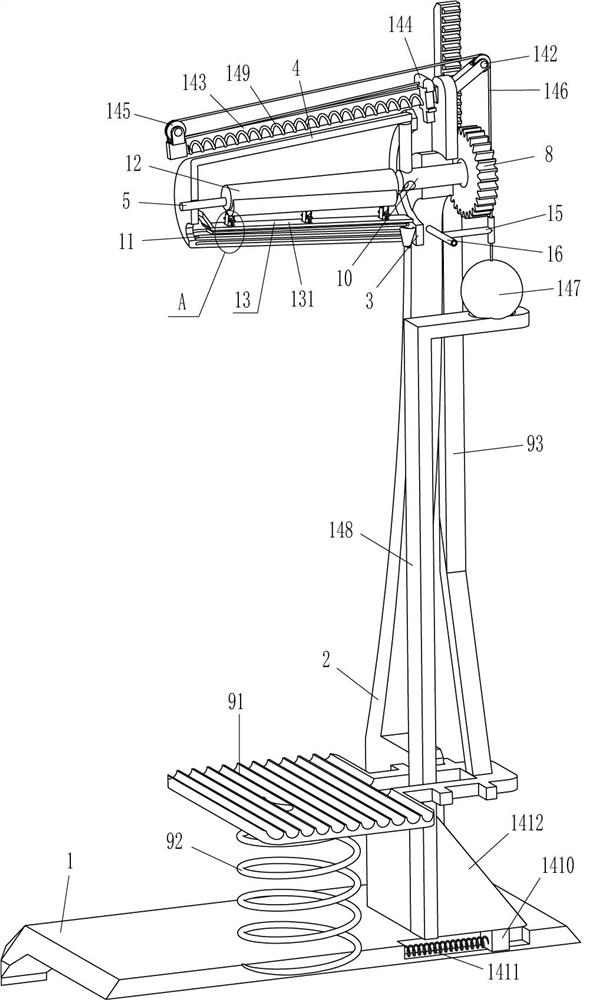

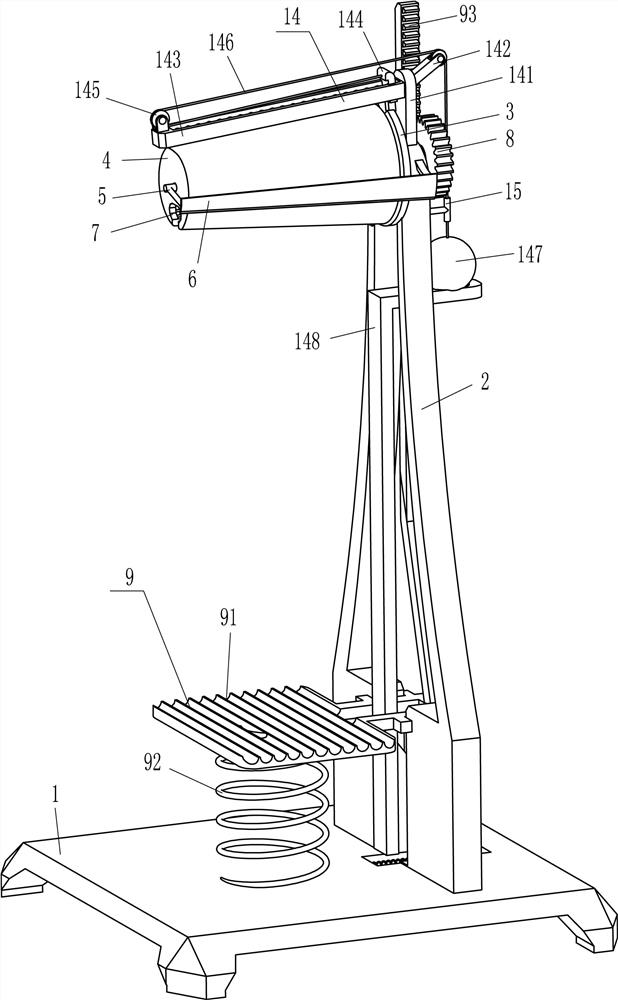

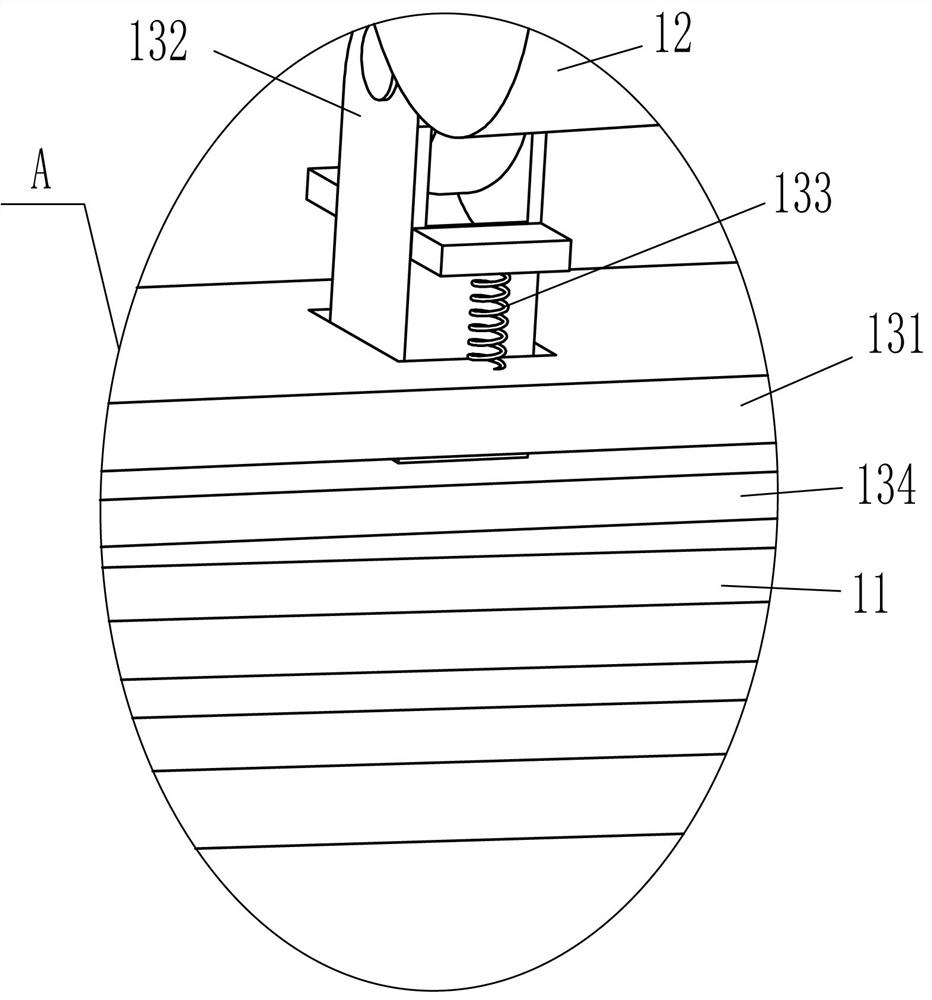

[0021] A kind of equipment for removing snail tails in batches for processing snails, such as Figure 1-Figure 3 As shown, it includes a base 1, a vertical plate 2, a notched annular plate 3, a conical cylinder 4, an L-shaped rod 5, a cutter 6, a gear 8, a driving mechanism 9, a rotating shaft 10, a limit rod 11, a camshaft 12 and A pressing mechanism 13, a riser 2 is fixedly connected in the middle of the top right side of the base 1, a driving mechanism 9 is provided between the riser 2 and the left side of the top of the base 1, and a rotating shaft 10 is connected in the middle of the upper part of the riser 2 in a rotating manner. The right end of 10 is fixedly connected with a gear 8 cooperating with the drive mechanism 9, the gear 8 is in contact with the drive mechanism 9, the left end of the rotating shaft 10 is fixedly connected with a conical cylinder 4, and the middle of the bottom of the conical cylinder 4 is horizontally provided with an opening 7 for placing snai...

Embodiment 2

[0028] On the basis of Example 1, such as figure 1 and figure 2 Shown, also comprise pusher mechanism 14, pusher mechanism 14 comprises support plate 141, the first guide pulley 142, return type plate 143, push plate 144, the second guide pulley 145, backguy 146, steel ball 147, L Type support bar 148, the 3rd spring 149, slide block 1410, the 4th spring 1411 and inclined block 1412, vertical plate 2 outer top middle is fixedly connected with support plate 141, and support plate 141 left side surface top is fixedly connected with back type plate 143 The push plate 144 is slidingly connected in the back-shaped plate 143, the lower part of the push plate 144 is in contact with the tapered tube 4, and the push plate 144 is also matched with the opening 7. The third spring 149 is connected between the left sides, the push plate 144 left side upper part is connected with a backguy 146, the second guide wheel 145 is installed on the left side of the return plate 143 top, and the f...

Embodiment 3

[0031] On the basis of embodiment 1 and embodiment 2, such as figure 1 and figure 2 As shown, it also includes a wire conduit 15 and a support frame 16, a support frame 16 is fixedly connected between the upper and lower sides of the vertical plate 2, a wire conduit 15 is fixedly connected to the right end of the support frame 16, and a pull wire 146 passes through the wire conduit 15 and its Cooperate.

[0032] When the steel ball 147 drives the push plate 144 to move to the left through the backguy 146, the wire guide 15 guides the backguy 146, and when the operator pulls the steel ball 147 to move up and reset, the backguy 146 is loosened, and the wire guide 15 also guides the backguy 146. guide. In this way, the pull wire 146 can be prevented from freely swinging and contacting the gear 8 to affect its rotation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com