Skid-mounted liquid additive accurate adding device and method

A liquid additive, adding device technology, applied in the direction of using electrical device flow control, instrumentation, control/regulation system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

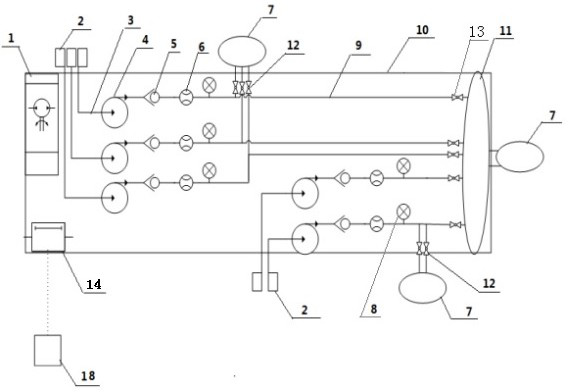

[0034] This embodiment relates to a skid-mounted liquid additive precise adding device, such as figure 1 As shown, it includes at least a skid frame 10 on which a variable frequency motor 1, a liquid storage tank 2, a liquid addition pump group and a liquid addition skid mixing manifold 11 are installed, and the liquid addition pump group is composed of a plurality of liquid addition pumps. The pumps 4 are formed in parallel, the liquid inlet of each liquid filling pump 4 is connected with the liquid storage tank 2 respectively, and the liquid outlet of each liquid filling pump 4 is divided into two paths, one of which is directly connected to the sand mixer or the sand mixer through the discharge manifold 9. The upper liquid manifold 7 of the mixing truck, the other way is connected to the liquid inlet of the mixing manifold 11 through the discharge manifold 9, and the liquid outlet of the mixing manifold 11 is connected to the sand mixer or the mixing truck. Liquid manifold ...

Embodiment 2

[0037] On the basis of Example 1, further, as figure 1 As shown, a control system 14 is also installed on the skid frame 10 , and the variable frequency motor 1 , the liquid filling pump 4 , the first automatic control valve 12 , and the second automatic control valve 13 are respectively electrically connected to the control system 14 . It is worth mentioning that the control system 14 adopts the control method of self-adaptive negative feedback. It only needs to adjust the addition and displacement of one liquid filling pump, and the system will adjust the discharge and displacement of other liquid filling pumps in real time according to different liquid formulas. .

[0038] Further, a flow control valve 5 , a mass flow meter 6 and a pressure transmitter 8 are installed on the discharge manifold 9 . The flow control valve 5 is a one-way valve, and the liquid can only pass in one direction, which can prevent the backflow of the liquid in the sand mixer or the upper liquid man...

Embodiment 3

[0043] Further, as figure 1 As shown in the figure, the skid-mounted liquid additive precise adding device also includes a remote data acquisition system 18, which is connected to the control system 14 in communication, and adopts the RS485 communication protocol to ensure data transmission during the working process. Stable and normal. The control system 14 completes the flow control of the liquid filling pump 4 and the on-off control of the first automatic control valve 12 and the second automatic control valve 13, and simultaneously controls the high-precision mass flowmeter 6 and the pressure transmitter on the discharge manifold. The value of the instrument is collected in real time and transmitted to the remote data collection system 18 of the instrument vehicle.

[0044] It is worth mentioning that the remote data acquisition system mainly collects and displays the data of liquid additives added to the device in real time in the instrument car, and can display the flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com